A kind of fermentation production method of C19~C21 long-chain dibasic acid

A long-chain dibasic acid and production method technology, applied in the field of biotechnology and biological fermentation, can solve the problems of increased production cost, low substrate conversion rate, unfavorable energy saving and emission reduction, etc., and achieve conversion efficiency improvement, efficient fermentation production, Reduce the effect of controlling low temperature hydropower resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Stability Verification of Example 1 Candida tropicalis 10468

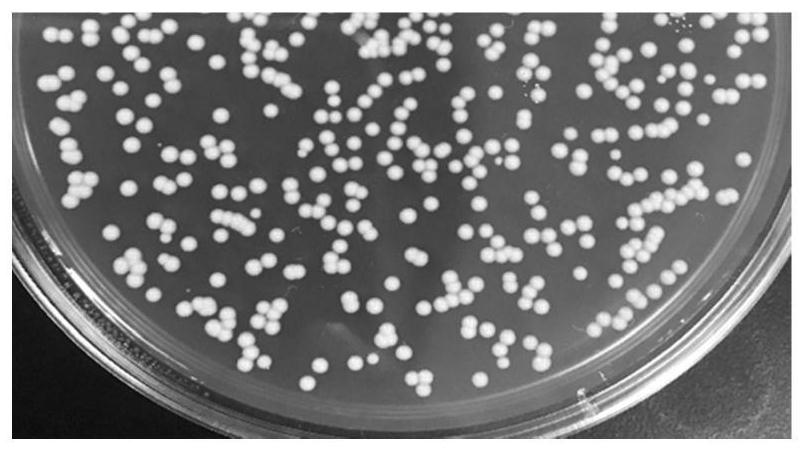

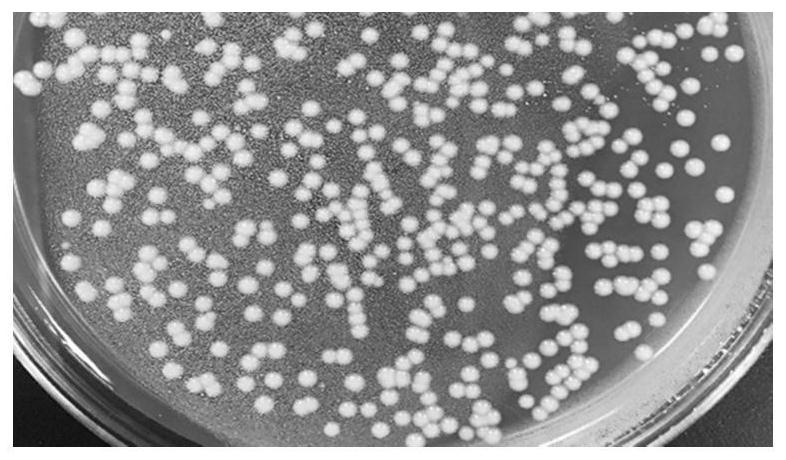

[0056] The Candida tropicalis 10468 of the present invention has good stability in shape, growth and production performance as verified by continuous passage experiments. After five passages, there was no obvious change in the colony morphology: the surface of the colony was smooth and moist, milky white, shiny, round, and the edges were neat (such as figure 1 and figure 2 shown). The results showed that the passage stability of Candida tropicalis 10468 was good.

[0057] This embodiment also provides a method for fermenting Candida tropicalis 10468 to produce dodecanedioic acid (DC12), specifically as follows:

[0058] The first-generation and sixth-generation strains were subjected to shake-flask fermentation to verify the performance of producing DC12. Take a glycerol tube seed of Candida tropicalis 10468 and insert it into the YPD activation medium, cultivate it for 24 hours and then inoculate it in...

Embodiment 2

[0061] This example provides a method for fermenting Candida tropicalis 10468 to produce DC19, specifically as follows:

[0062] Take a glycerol tube seed of Candida tropicalis 10468 and put it into the YPD activation medium, cultivate it for 24 hours, then put the culture solution into the seed medium. The formula of the seed medium is as follows: sucrose 20g / L, corn steep liquor 2g / L, yeast extract 6g / L, potassium dihydrogen phosphate 8g / L, urea 2g / L, n-C19 33mL / L; After culturing for 48 hours, the OD of the seed solution was measured 620 When it reached 0.8 (measured after 30-fold dilution), the seed solution was inoculated into the shake flask containing the fermentation medium. The fermentation medium includes the formula as follows: sucrose 40g / L, corn steep liquor 5g / L, yeast extract 5g / L, potassium dihydrogen phosphate 8g / L, potassium nitrate 4g / L, sodium chloride 1.5g / L, urea 0.5g / L L. The substrate n-alkane n-C19 was added to the fermentation medium in an amount o...

Embodiment 3

[0064] This example provides a method for fermenting Candida tropicalis 10468 to produce DC19, specifically as follows:

[0065] Take a glycerol tube seed of Candida tropicalis 10468 and put it into the YPD activation medium, cultivate it for 24 hours, then put the culture solution into the seed medium. The formula of the seed medium is as follows: sucrose 20g / L, corn steep liquor 2g / L, yeast extract 6g / L, potassium dihydrogen phosphate 8g / L, urea 2g / L, n-C19 33mL / L; After culturing for 48 hours, the OD of the seed solution was measured 620 When it reached 0.8 (measured after 30-fold dilution), the seed solution was inoculated into the shake flask containing the fermentation medium. The formula of the fermentation medium is as follows: sucrose 40g / L, corn steep liquor 5g / L, yeast extract 5g / L, potassium dihydrogen phosphate 8g / L, potassium nitrate 4g / L, sodium chloride 1.5g / L, urea 0.5g / L . The substrate n-alkane n-C19 was added to the fermentation medium in an amount of 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com