Preparation of functionalized organic magnesium salt and application of functionalized organic magnesium salt in preparation of polyester composite material

A polyester composite material and composite material technology, applied in the field of preparation of functional organic magnesium salts, can solve the problems of high addition amount, poor matrix compatibility, and affecting the mechanical properties of the matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

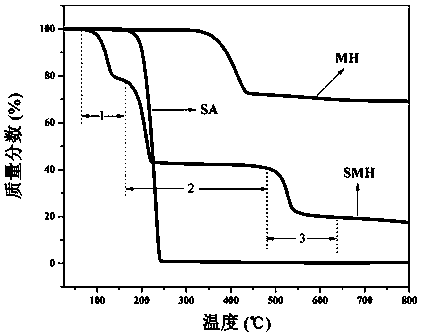

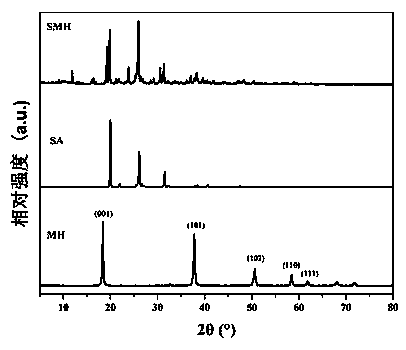

[0029] (1) Organic functionalization of magnesium hydroxide: Dissolve 16.28g of succinic acid in 300mL of distilled water, add 4g of magnesium hydroxide after the succinic acid is completely dissolved, stir magnetically at 90°C for 2 hours, remove the distilled water, and dry in vacuum to obtain The white powdery solid is the functionalized organic magnesium salt SMH;

[0030] (2) Preparation of flame-retardant polyester (PET) composite material: Take 830.65g of terephthalic acid, 403.44g of ethylene glycol, 0.29g of antimony trioxide, and 24.6g of SMH, and mix them into a 1.5L reactor. Check the airtightness of the instrument, slowly pass in nitrogen to remove the air in the kettle, and control the temperature at 200°C for esterification reaction. When the column top temperature is lower than 100°C, the esterification reaction is completed and drained. Then the system enters the polycondensation stage. After the first semi-vacuum polycondensation for 0.5h, the temperature is ...

Embodiment 2

[0033] (1) Organic functionalization of magnesium oxide: Take 34g of p-aminobenzoic acid and dissolve it in 500mL of distilled water; after the p-aminobenzoic acid is completely dissolved, add 5g of magnesium oxide, stir magnetically at 80°C for 3h, remove the distilled water, and dry in vacuum. The resulting white powdery solid is the functionalized organic magnesium salt PMO;

[0034] (2) Preparation of flame-retardant polyester (PET) composite material: Take 830.65g of terephthalic acid, 403.44g of ethylene glycol, 0.29g of antimony trioxide, and 50g of PMO, and mix them into a 1.5L reactor. Check the airtightness of the instrument, slowly pass in nitrogen to remove the air in the kettle, and control the temperature at 220°C for esterification reaction. When the column top temperature is lower than 100°C, the esterification reaction is completed and drained. Then the system enters the polycondensation stage. After the semi-vacuum polycondensation for 0.5h, the temperature i...

Embodiment 3

[0037] (1) Organic functionalization of magnesium carbonate: Dissolve 11.25g of pimelic acid in 500mL of distilled water. After the pimelic acid is completely dissolved, add 3g of magnesium carbonate, stir magnetically at 90°C for 5h, remove the distilled water, and dry in vacuum to obtain The white powdery solid is organic magnesium salt PMC;

[0038] (2) Preparation of flame-retardant polyester (PET) composite material: Take 830.65g of terephthalic acid, 403.44g of ethylene glycol, 0.29g of antimony trioxide, and 74g of PMC, and mix them into a 1.5L reactor. Check the airtightness of the instrument, slowly pass in nitrogen to remove the air in the kettle, and control the temperature at 240°C for esterification reaction. When the column top temperature is lower than 100°C, the esterification reaction is completed and drained. Then the system enters the polycondensation stage. After polycondensation in semi-vacuum for 1.0h, the temperature is slowly raised to 280°C for high-va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| peak heat release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com