A kind of supported metallocene catalyst and its preparation method and application

A metallocene catalyst and metallocene compound technology, applied in the field of metallocene catalysts, can solve problems such as inability to prepare bimodal polyethylene, and achieve the effects of improving catalytic polymerization activity, high polymerization activity, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

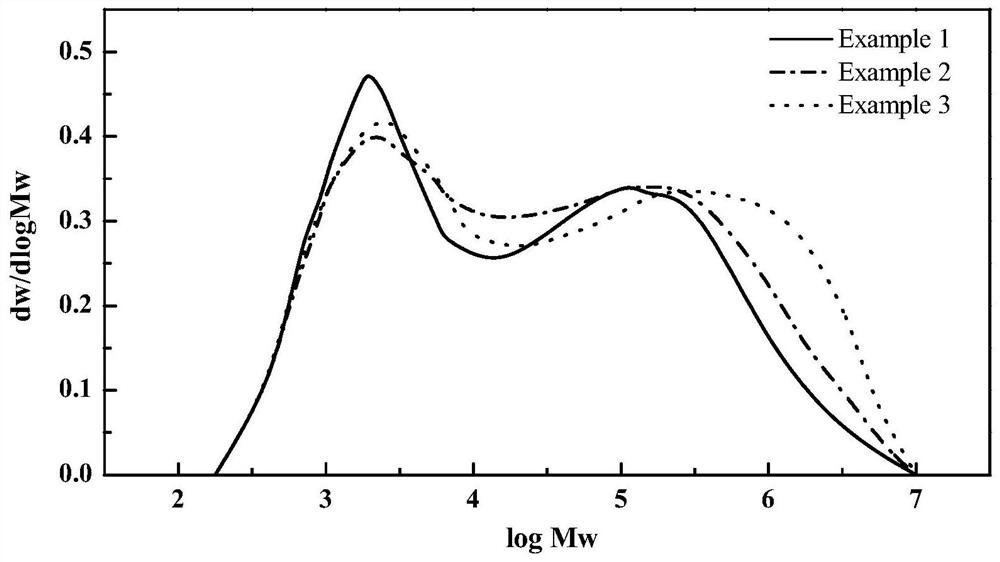

Image

Examples

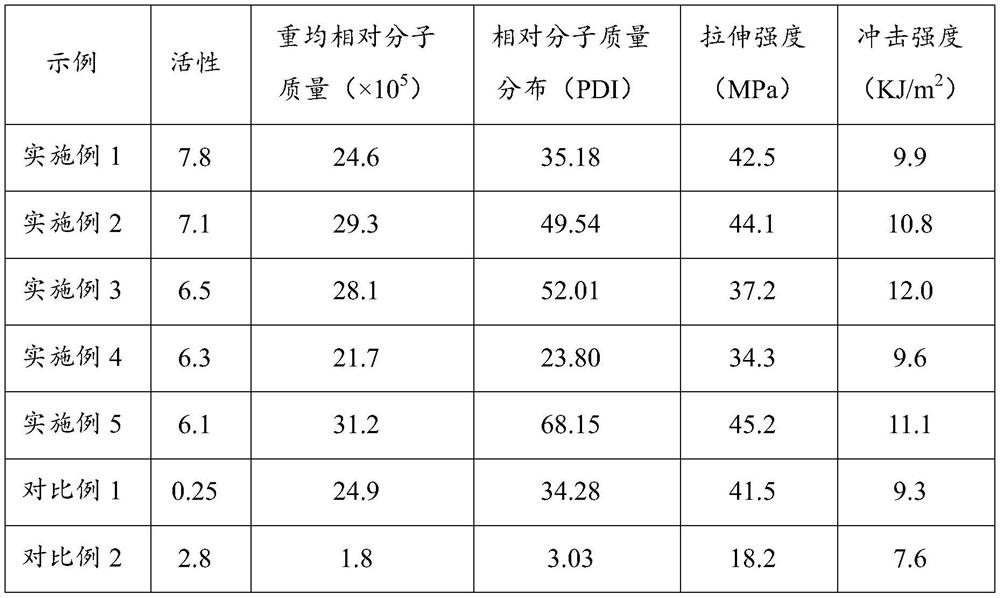

Embodiment 1

[0046] This embodiment provides a supported metallocene catalyst and its preparation method, specifically,

[0047] Preparation of the first carrier: under nitrogen protection, add 0.65g antimony trichloride and 400ml tetrahydrofuran (THF) to the reactor, start stirring, add 13.77g silica gel (parameter: specific surface area is 220m 2 / g, the pore volume is 0.75cm 3 / g, with an average particle size of 75 μm), heated to 70°C and stirred for 2 hours, then heated to 80°C to evaporate and remove the solvent to obtain a white solid powder; the white solid powder was first vacuum-dried at 100°C for 2 hours, and then dried at 300°C After vacuum drying for 10 hours, the antimony chloride / silica carrier was obtained; under the protection of nitrogen, 4.66g of antimony chloride / silica carrier was added to the reactor, 70ml of toluene was added to disperse into a suspension, and 2.44g of triethyl base aluminum, heated to 40° C., stirred for 6 h, then washed three times with toluene, t...

Embodiment 2

[0051] This embodiment provides a supported metallocene catalyst and its preparation method, specifically,

[0052] Preparation of the first carrier: under nitrogen protection, add 0.48g antimony pentachloride and 350ml THF in the reactor, start stirring, add 7.28g silica gel in the reactor (parameter: specific surface area is 380m 2 / g, the pore volume is 1.02cm 3 / g, with an average particle size of 58 μm), heated to 65°C and stirred for 3 hours, then heated to 80°C to evaporate and remove the solvent to obtain a white solid powder; the white solid powder was first vacuum-dried at 100°C for 2 hours, and then dried at 300°C After vacuum drying for 10 hours, the antimony chloride / silica carrier was obtained; under the protection of nitrogen, 4.75g of antimony chloride / silica carrier was added to the reactor, 60ml of toluene was added to disperse into a suspension, and 1.57g of triiso Butylaluminum was heated to 60° C., stirred for 3 hours, washed three times with toluene, was...

Embodiment 3

[0056] This embodiment provides a supported metallocene catalyst and its preparation method, specifically,

[0057] Preparation of the first carrier: under nitrogen protection, add 2.49g antimony pentachloride and 350ml THF in the reactor, start stirring, add 5.31g silica gel in the reactor (parameter: specific surface area is 490m 2 / g, the pore volume is 1.30cm 3 / g, the average particle size is 50 μm), heated up to 80°C and stirred for 0.5h, then evaporated to remove the solvent to obtain a white solid powder; the white solid powder was first vacuum-dried at 100°C for 2h, and then vacuum-dried at 300°C for 10h Finally, the antimony chloride / silica carrier was obtained; under the protection of nitrogen, 2.76g of antimony chloride / silica carrier was added to the reactor, and after adding 60ml of toluene to disperse into a suspension, 2.76g of monochlorodiethyl aluminum, heated to 50° C., stirred for 4 hours, washed three times with toluene, then washed with hexane, and dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com