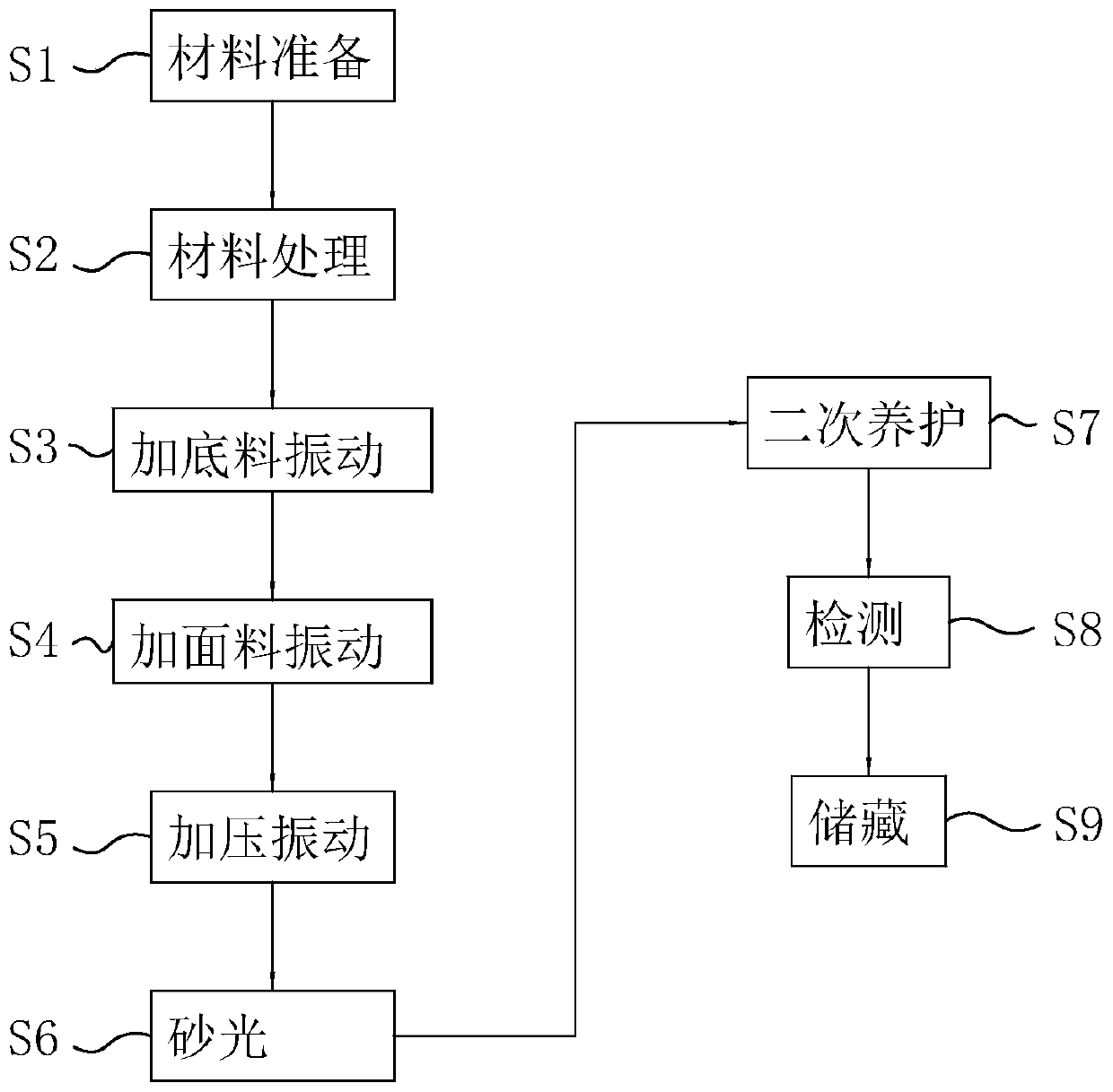

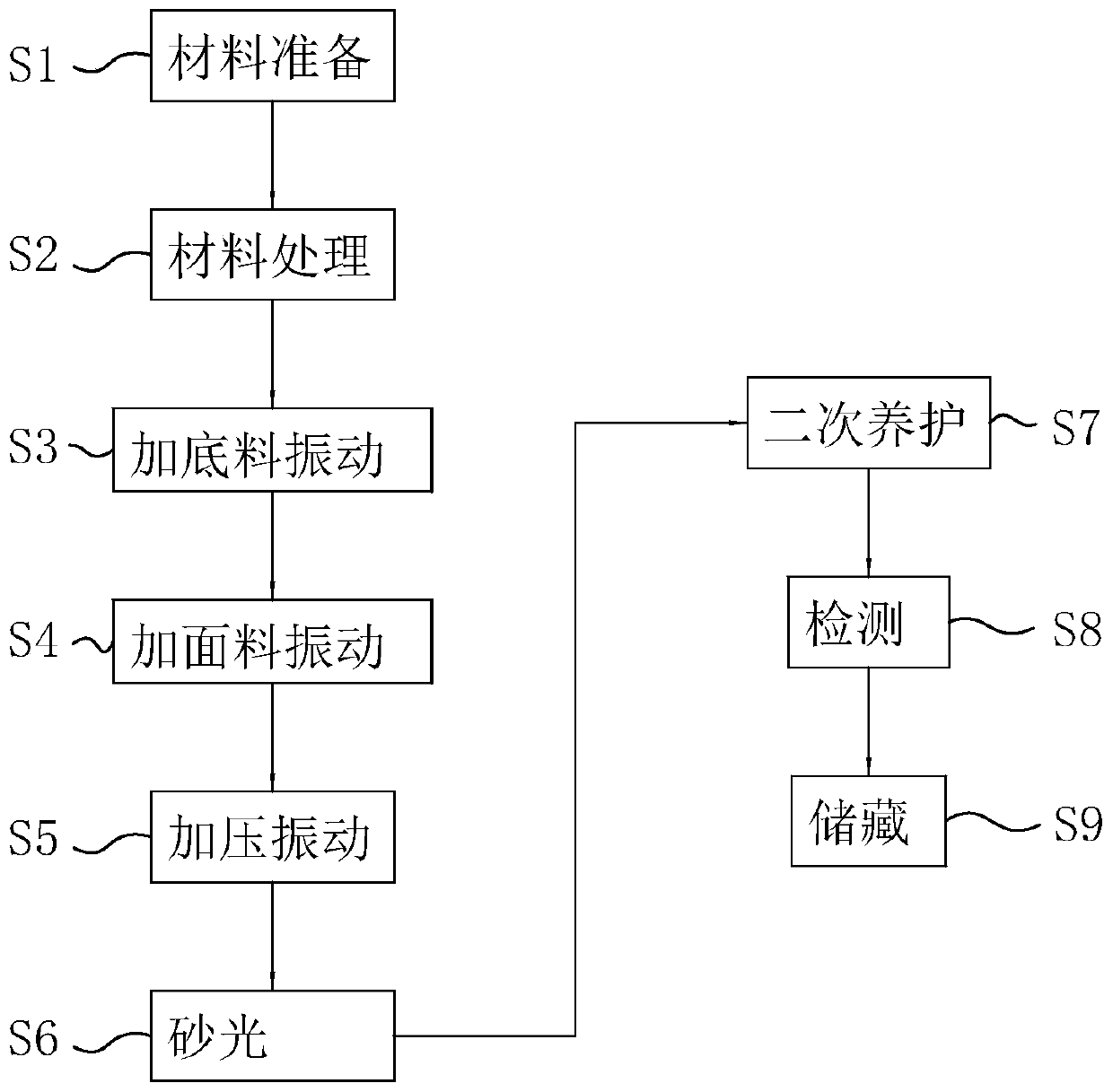

Process for preparing reclaimed concrete pavement bricks

A recycled concrete and preparation technology, which is applied to roads, roads, and pavements paved with prefabricated blocks, etc., can solve the problems that construction waste cannot be effectively used, and building materials cannot meet the performance requirements of use, so as to achieve good water retention and permeability. Permeability, elimination of performance defects, excellent effect of isotropic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: A kind of preparation technology of regenerated concrete pavement brick, comprises base material and lining, and base material comprises the raw material of following parts by weight:

[0054] Construction waste recycled aggregate: 42 parts;

[0055] Gravel 0-5mm: 10 parts;

[0056] Mixed slag: 20 parts;

[0057] Cement P.C32.5: 10 parts;

[0058] Fly ash: 8 parts;

[0059] Gelling agent: 3 parts;

[0060] Water-swellable inorganic: 4.5 parts;

[0061] Polycarboxylate superplasticizer powder 1.5%;

[0062] Sulfamate superplasticizer powder 0.6%;

[0063] 0.4 parts of dispersant;

[0064] Wherein the material of the gelling agent comprises the following weight proportions: 30% of light magnesium oxide, 9% of ferrous sulfate, 12% of magnesium sulfate, 9% of magnesium chloride, 4% of sulfuric acid, 0.15% of dispersant, 0.15% of sodium gluconate, water 35.7%. Under the premise of keeping all physical indicators unchanged, it has good water retention, ...

Embodiment 2

[0082] Example 2: The difference from Example 1 is that the bottom material includes the following raw materials in parts by weight: 47.4 parts of recycled aggregate from construction waste, 12 parts of gravel 0-5mm, 18 parts of mixed water slag, cement P.C32. 5 10 parts, 5 parts of fly ash, 5 parts of gelling agent, 1.5 parts of water-swellable inorganic, 0.6% of polycarboxylate superplasticizer powder, 0.3% of sulfamate superplasticizer powder, and 0.2 part of dispersant.

[0083] The gelling agent comprises the following raw materials in parts by weight: light magnesium oxide 35%, ferrous sulfate 9%, magnesium sulfate 8%, magnesium chloride 3%, ammonium sulfate 2%, dispersant 0.05%, sodium gluconate 0.05%, water 39.9%.

[0084] The fabric includes the following raw materials in parts by weight: 68% of fine sand, 22.5% of white cement, 5% of quartz sand, 2% of pigment, and 2.5% of water-reducing and color-retaining agent.

Embodiment 3

[0085] Embodiment 3: The difference from Example 1 is that the base material includes the following raw materials in parts by weight: 55 parts of construction waste recycled aggregate, 10.4 parts of crushed stone 0-5mm, 14 parts of mixed water slag, cement P.C32 .5 10 parts, 5 parts of fly ash, 3 parts of gelling agent, 1.5 parts of water-swellable inorganic, 0.6% of polycarboxylate superplasticizer powder, 0.3% of sulfamate superplasticizer powder, and 0.2 parts of dispersant.

[0086] The gelling agent comprises the following raw materials in parts by weight: 40% of light magnesium oxide, 9% of ferrous sulfate, 8% of magnesium sulfate, 3% of magnesium chloride, 2% of ammonium sulfate, 0.05% of dispersant, 0.05% of sodium gluconate, water 37.9%.

[0087] The fabric includes the following raw materials in parts by weight: 60% of fine sand, 30% of white cement, 5% of quartz sand, 2.5% of pigment, and 2.5% of water-reducing and color-retaining agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com