Metal pipe rolling machine

A metal tube and winding machine technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of easy scratching of metal tubes, uneven tube arrangement, etc. The tubes are evenly arranged to reduce the effect of gravity extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

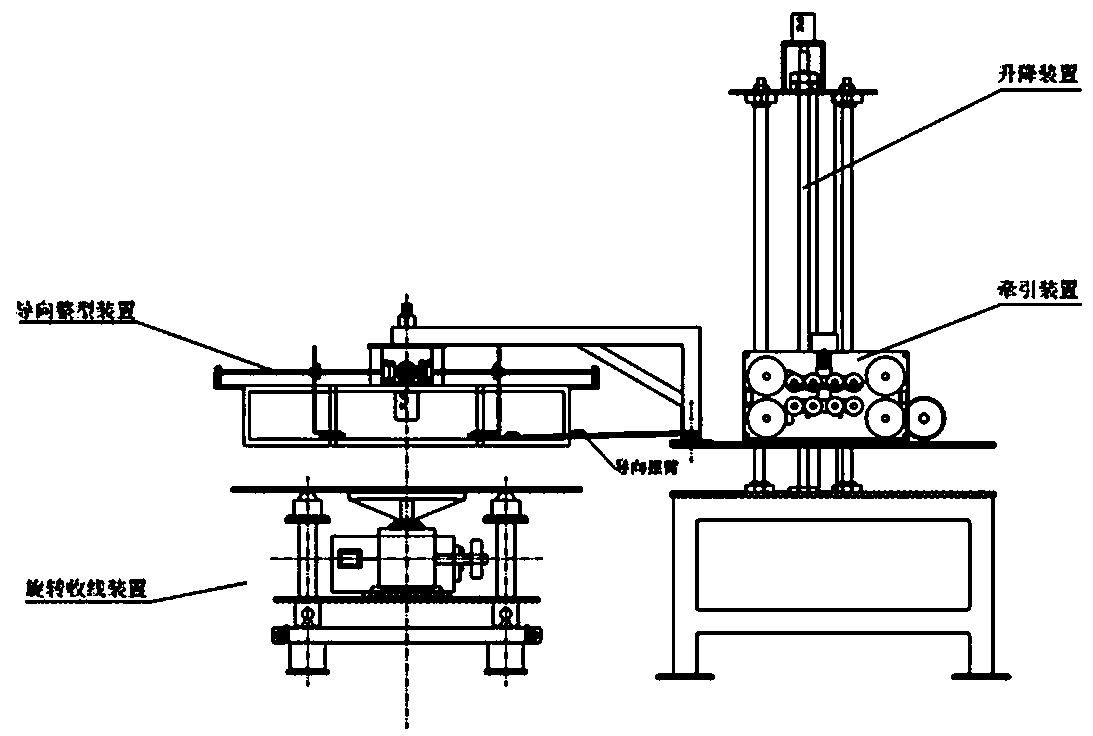

[0025] A metal tube winding machine, such as figure 1 As shown, it includes a lifting device, a guide rounding device, a traction device 130, and a rotating wire take-up device. The guiding rounding device and the traction device 130 are both fixed on the lifting device, and the rotating wire take-up device is arranged on one side of the lifting device, and the guiding rounding device is directly below. After the metal tube passes through the traction device 130, it passes through a guide swing arm around the guide to form a round device. After the guide to form a round device, it is pre-bent and falls on the rotating wire take-up device. The lifting device drives the guiding and forming device to move up and down. The rotating wire take-up device winds the metal tube into a disc body by rotating.

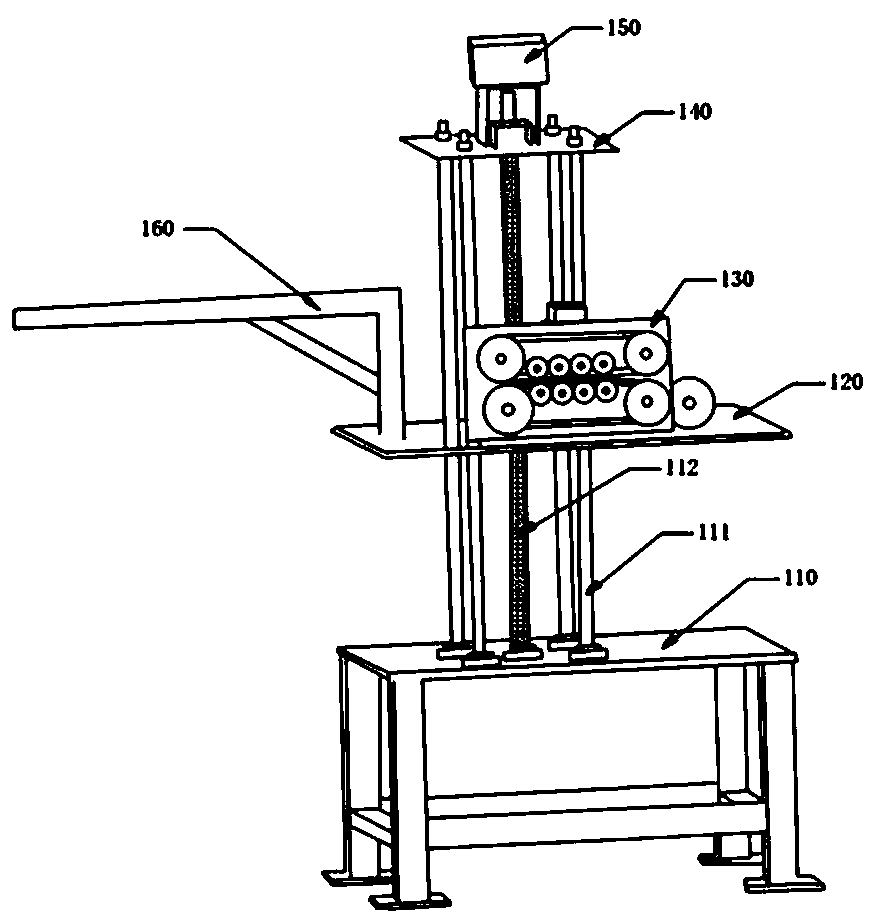

[0026] Such as figure 2 As shown, the lifting device includes a base 110, a screw 112 vertically arranged on the base 110, a lifting plate 120, a top plate 140, and a first motor 150...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com