A production method for improving sintered gas permeability of thick material layer

A production method and thick material layer technology, which is applied in the field of iron and steel metallurgy, can solve the problems of reducing the specific gravity of the lower material layer stack, increasing the cost, and wearing and tearing the support device, so as to achieve the effect of saving transformation costs and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

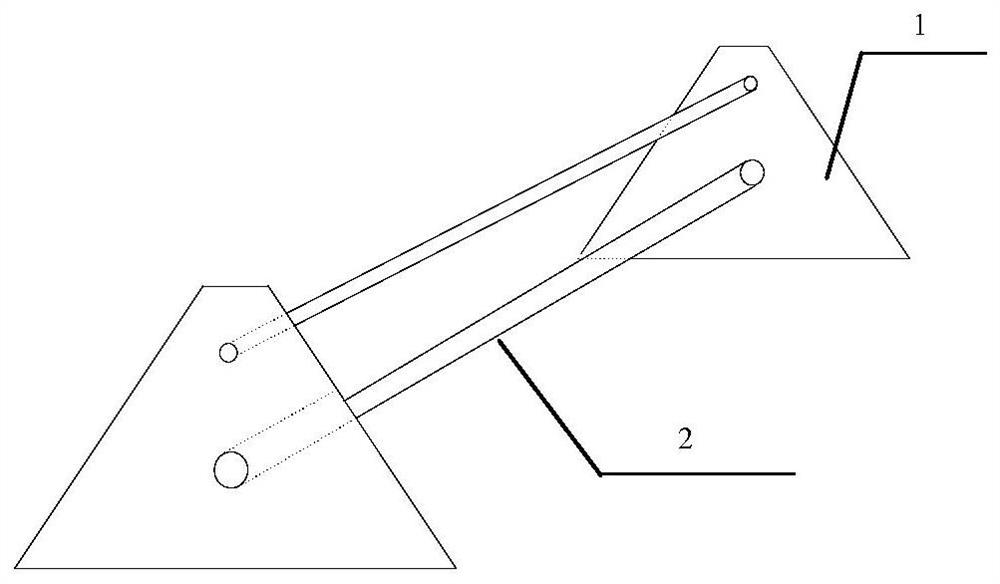

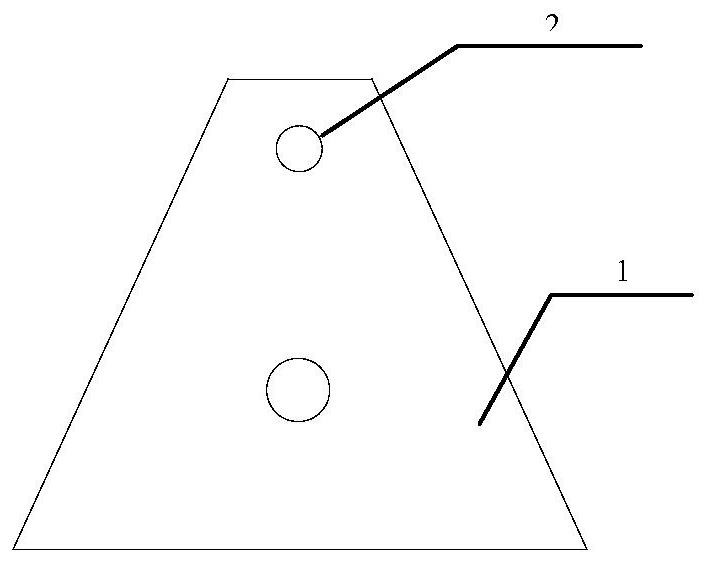

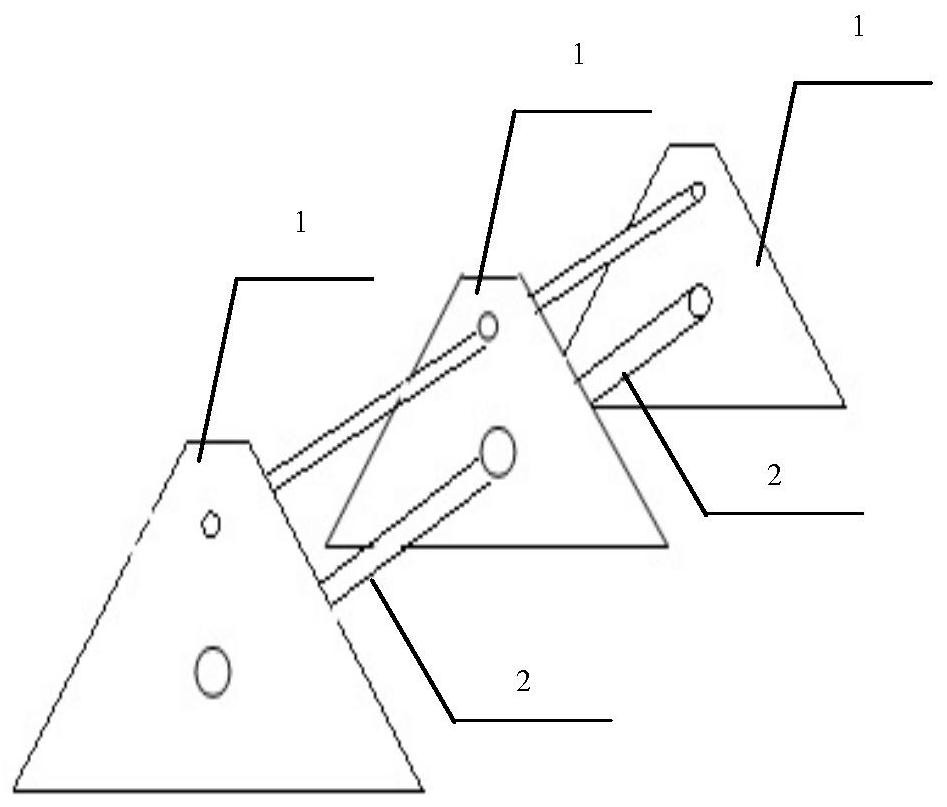

Embodiment 1

[0019] When a 260 square meter sintering machine is produced, the height of the trolley baffle is 750mm, the concentrate is more than 70%, the height of the support device is 260mm, and the support device is composed of 2 separate supports, and the material of the support is 25% ore return , 25% steelmaking converter slag, 10% sintering dust, 10% iron oxide powder and 30% cement, the width between two supports is 1100mm, and the length of each support is 500mm. Before sintering the cloth, a set of supporting devices is dropped into the middle of the sintering trolley. The interior of the supporting devices is connected by wood-based materials. After the sintering process, at the tail of the sintering machine, the supporting device and the sintered ore are crushed by a single-toothed roller, and then enter the ring cooler for cooling, and then the finished ore is screened and then enters the blast furnace.

Embodiment 2

[0021] When a sintering machine of 405 square meters is produced, the height of the baffle plate of the trolley is 900mm, and the height of the support device is 450mm. The support device is composed of 3 separate supports, and the material of the supports is 20% reclaimed ore and 20% steelmaking converter slag , 5% sintering dust, 10% iron oxide powder and 45% cement, the width between the two brackets is 1200mm, and the length of each bracket is 400mm. Before sintering and distributing, 2 sets of supporting devices are dropped into the middle of the sintering trolley. The interior of the supporting devices is connected by wood-based materials. After the sintering process, at the tail of the sintering machine, the supporting device and the sintered ore are crushed by a single-toothed roller, and then enter the ring cooler for cooling, and then the finished ore is screened and then enters the blast furnace.

Embodiment 3

[0023] When a 600 square meter sintering machine is produced, the height of the trolley baffle is 1200mm, and the height of the supporting device is 650mm. The supporting device is composed of 4 individual supports, and the material of the supports is 20% reclaimed ore and 15% steelmaking converter slag , 5% sintering dust, 5% iron oxide powder and 55% cement, the width between the two brackets is 1000mm, and the length of each bracket is 600mm. Before sintering the cloth, three sets of supporting devices are dropped into the middle of the sintering trolley. The interior of the supporting devices is connected by wood-based materials. After the sintering process, at the tail of the sintering machine, the supporting device and the sintered ore are crushed by a single-toothed roller, and then enter the ring cooler for cooling, and then the finished ore is screened and then enters the blast furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com