Raw coal feeding and screening technique

A raw coal and process technology, which is applied in the field of raw coal feeding and screening technology, can solve the problems of high labor intensity, large gangue volume, and conveying bandwidth, etc., and achieve the effect of improving the purity of raw coal, ensuring the quality of rough selection, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

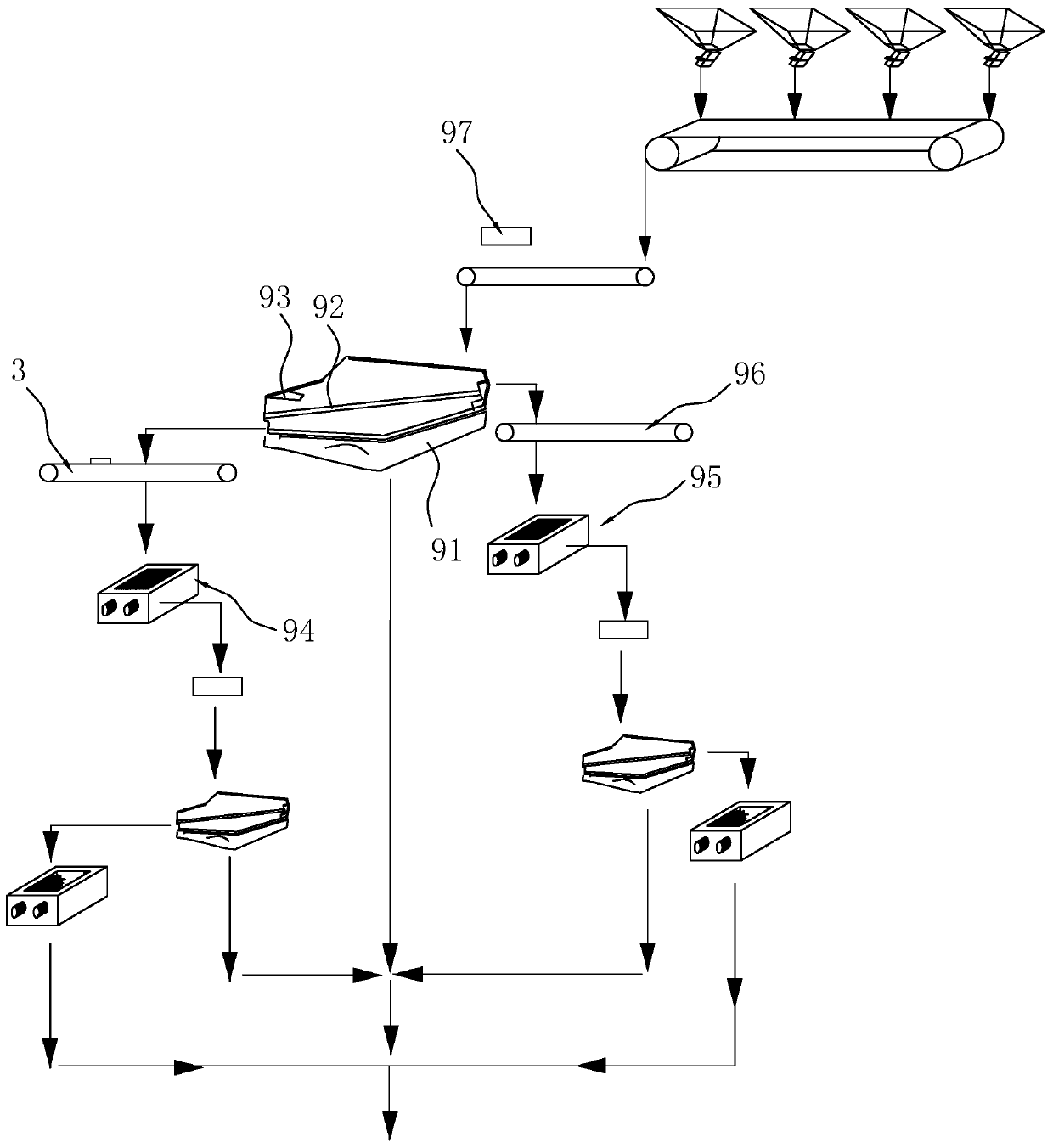

[0044] Embodiment: a kind of raw coal feeding screening process, such as figure 1 shown, including the following steps:

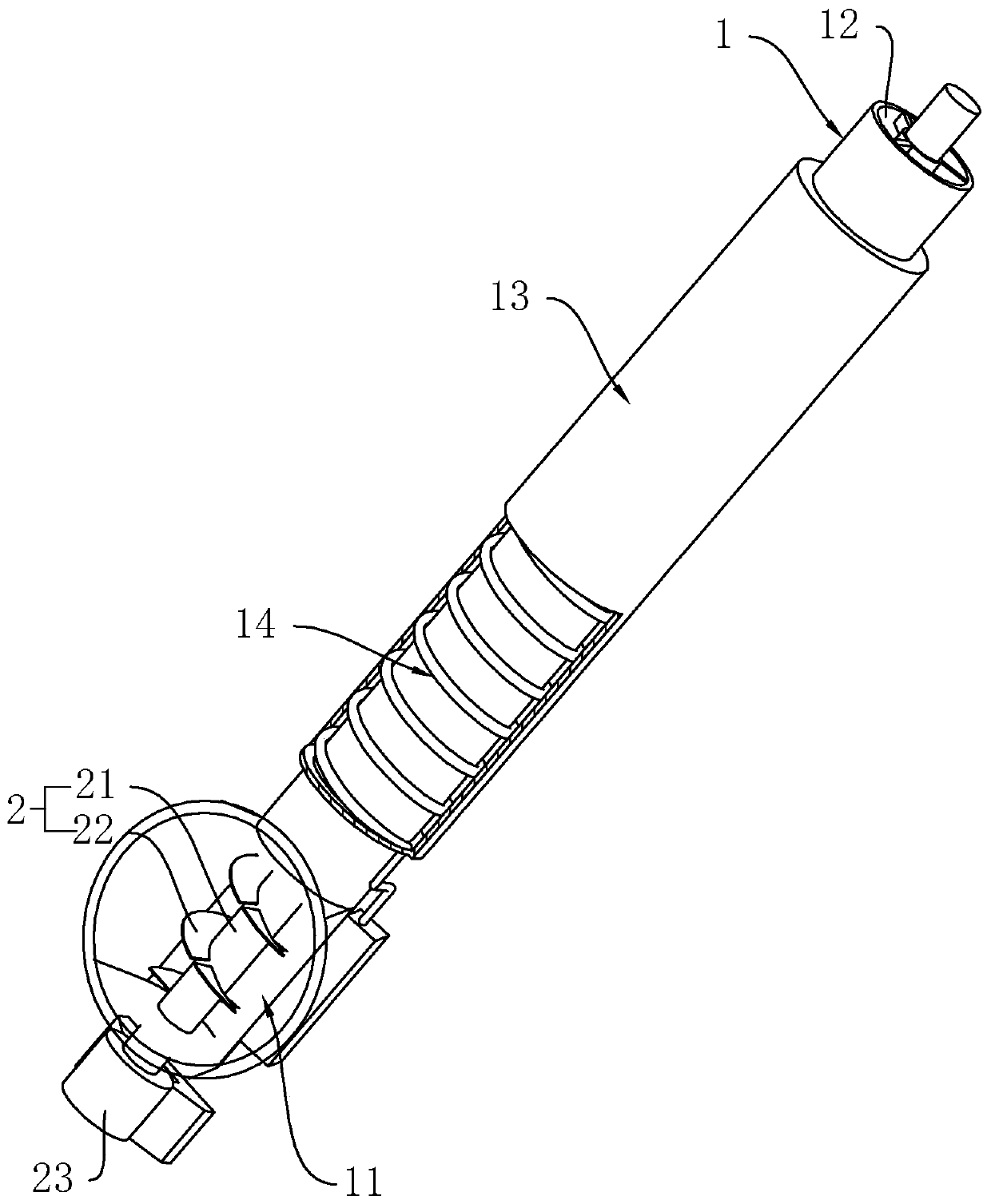

[0045] Step 1, Raw coal feeding: transfer the raw coal to the dispersing heating feeding equipment, heat, disperse and complete the conveying of the raw coal, realize raw coal feeding, and the heating temperature is 40-55°C;

[0046] Step 2, primary magnetic screening of raw coal: performing magnetic screening through the iron remover 97 to initially separate the iron-containing impurities in the raw coal that has been loaded in step 1;

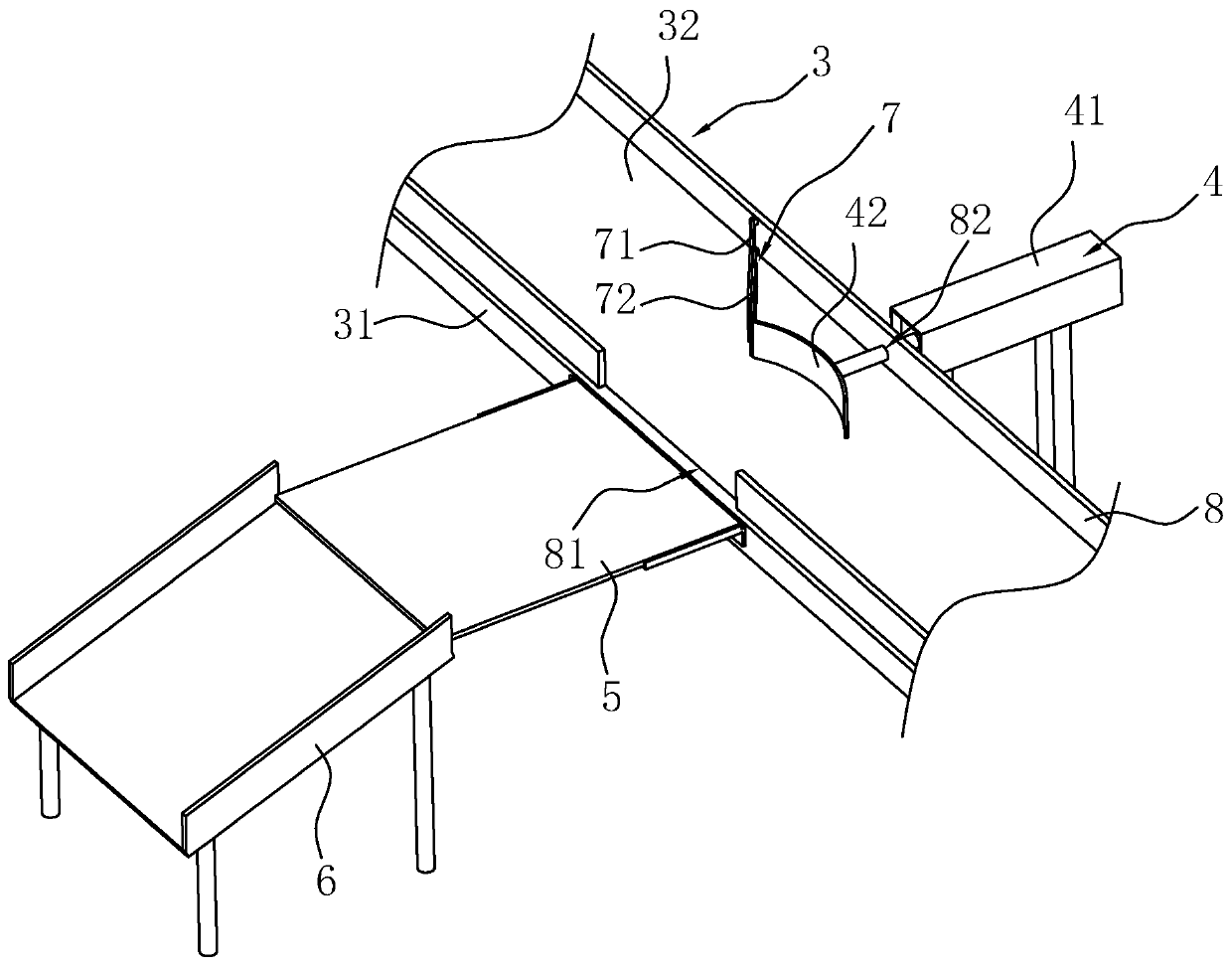

[0047] Step 3, primary grading of raw coal: sieve the raw coal processed in step 2 through the first screener 9 to obtain the coarse sieve, heavy materials containing gangue and light materials, wherein the particle size of the coarse sieve is 0 -50mm, the heavy material containing gangue includes gangue and raw coal A with a particle size greater than 110mm, and the light material is raw coal B with a particle size of 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com