Graphene antibacterial mask filter material and preparation method and application thereof

A technology of filter material and antibacterial material, which is applied in the field of graphene antibacterial mask filter material and its preparation, can solve problems such as the complexity of the collection process, and achieve the effects of good mechanical properties, enhanced structural strength, and good adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

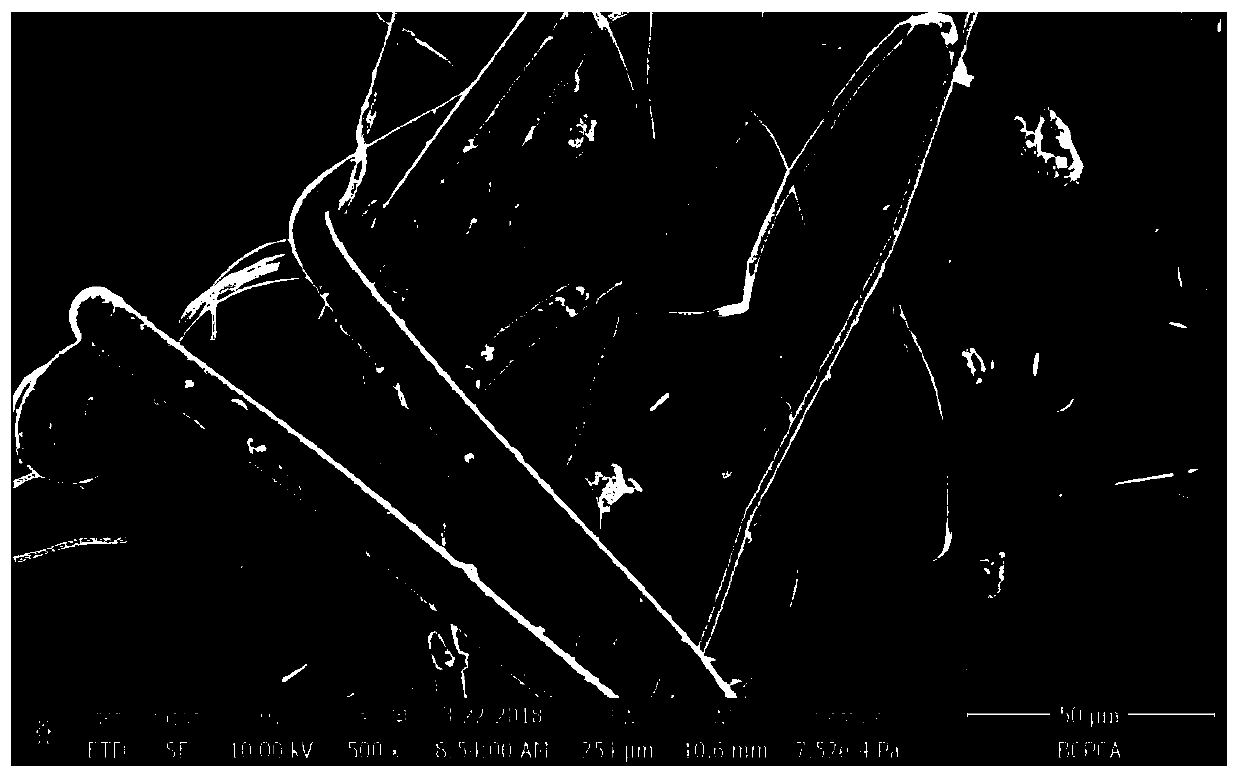

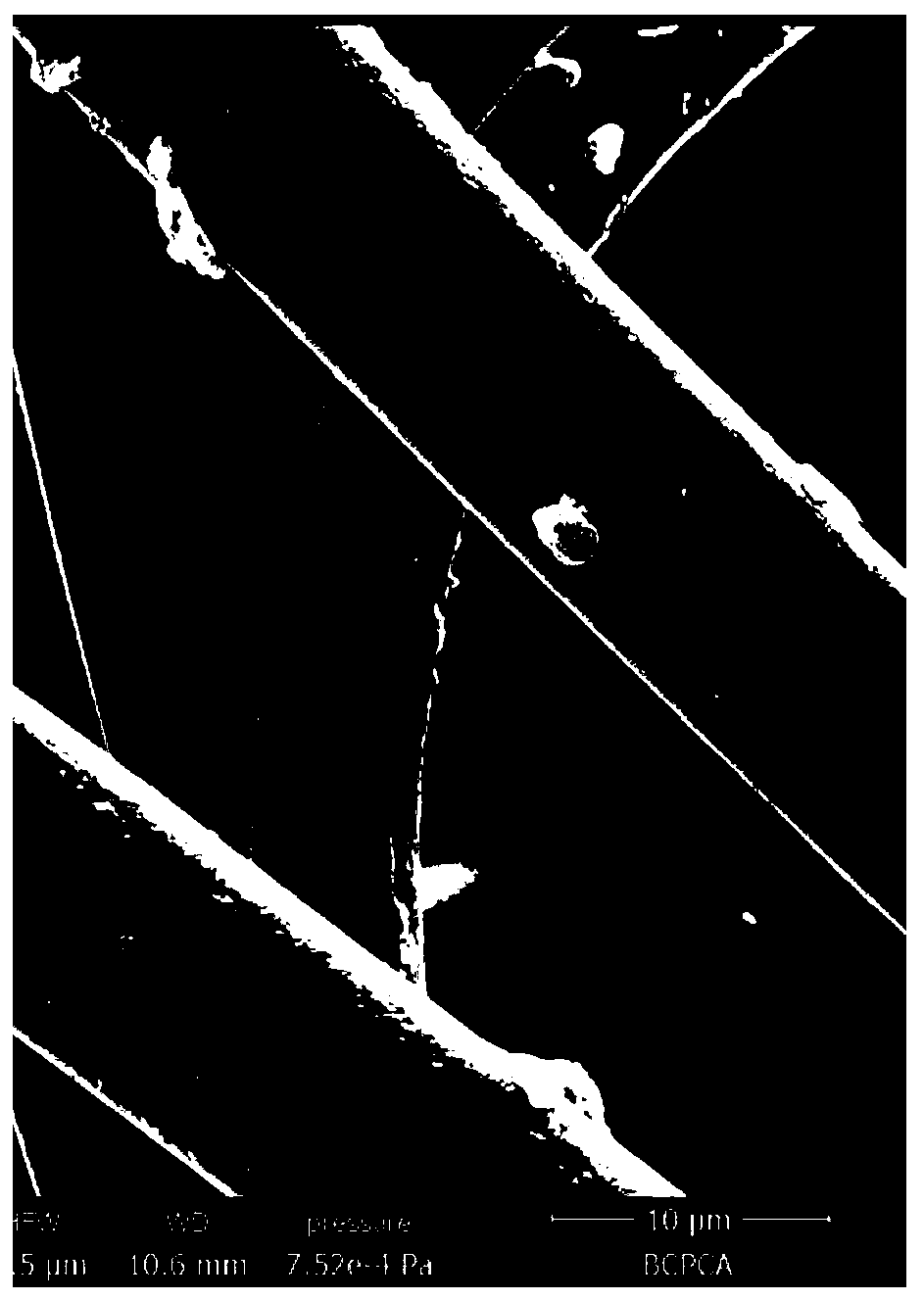

Image

Examples

Embodiment 1

[0023] A preparation method of graphene mask antibacterial material, comprising the steps of:

[0024] (1) Preparation of antibacterial primary masterbatch: Weigh 0.5g of graphene nanosheets, 3g of dispersant, and 95g of pp resin material, and mix the three raw materials evenly, and then add the mixture to the twin-screw extruder , and set the temperature of each section of the extruder to 230°C, start the extruder to extrude the filaments, then cool, granulate, and dry to obtain the antibacterial primary masterbatch;

[0025] (2) Melt-blown process: Take 10g of the antibacterial primary masterbatch prepared in step (1) and 90g of polypropylene resin material, mix the two materials evenly, and send them to the melt-blown equipment for melt-blown spinning. The temperature is 250°C, and the receiving distance is: 18cm; the melt is sprayed from the screw to the spinning assembly and then to the spinneret, and is drawn by high-temperature and high-speed air to make melt-blown ultr...

Embodiment 2

[0028] A preparation method of graphene mask antibacterial material, comprising the steps of:

[0029] (1) Preparation of antibacterial primary masterbatch: Weigh 1g of graphene nanosheets, 3g of dispersant, and 96g of pp resin material, and mix the three raw materials evenly, and then add the mixture to the twin-screw extruder , and set the temperature of each section of the extruder to 240°C, start the extruder to extrude the filaments, then cool, granulate, and dry to obtain the antibacterial primary masterbatch;

[0030] (2) Melt-blown process: get 12g of antibacterial primary masterbatch prepared in step (1) and 88g of polypropylene resin material, mix the two materials uniformly and send them into melt-blown equipment for melt-blown spinning, and melt-blown spinning The temperature is 250°C, and the receiving distance is: 18cm; the melt is sprayed from the screw to the spinning assembly and then to the spinneret, and is drawn by high-temperature and high-speed air to mak...

Embodiment 3

[0033] A preparation method of graphene mask antibacterial material, comprising the steps of:

[0034] (1) Preparation of antibacterial primary masterbatch: Weigh 0.8g of graphene nanosheets, 2g of dispersant, and 97g of pp resin material, and mix the three raw materials evenly, and then add the mixture to the twin-screw extruder , and set the temperature of each section of the extruder to 250°C, start the extruder to extrude the filaments, then cool, granulate, and dry to obtain the antibacterial primary masterbatch;

[0035] (2) Melt-blown process: get 15g of antibacterial primary masterbatch prepared in step (1) and 85g of polypropylene resin material, mix the two materials uniformly and send them into melt-blown equipment for melt-blown spinning, and melt-blown spinning The temperature is 250°C, and the receiving distance is: 18cm; the melt is sprayed from the screw to the spinning assembly and then to the spinneret, and is drawn by high-temperature and high-speed air to m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com