Medical pipe and sinus tract rinser

A technology for outer tubes and channels, applied in the field of medical tubes and cavity flushers, can solve problems such as fracture failure, potential safety hazards, difficulties in bending and adjustment, etc., and achieve the effect of improving service life and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

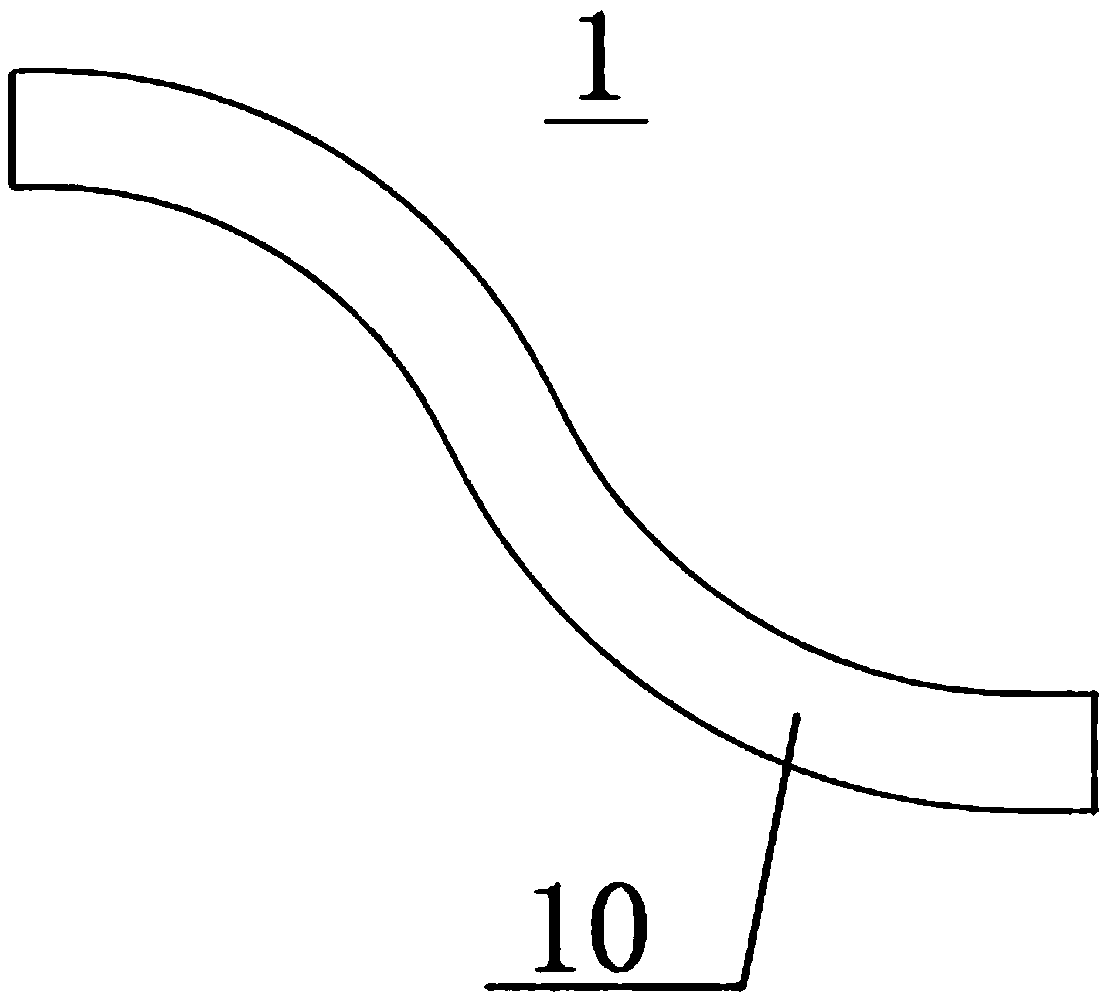

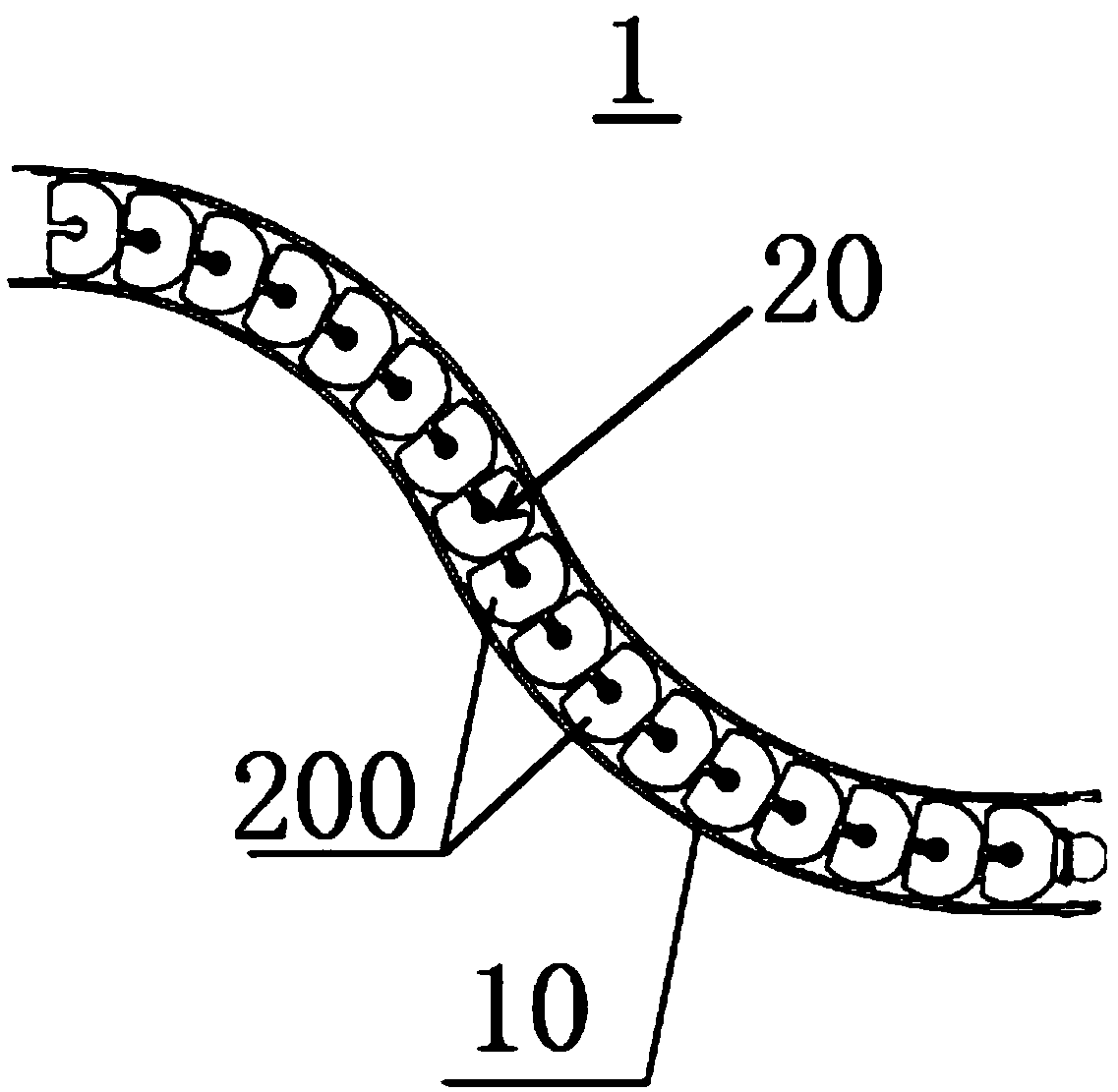

[0062] Figure 1A It is a schematic diagram of the appearance of a medical tube according to Embodiment 1 of the present invention, Figure 1B yes Figure 1A A schematic diagram of the internal structure of the medical tube shown. refer to Figure 1A with Figure 1B , the medical tube 1 includes an outer tube 10 and a bending mechanism 20 . A detailed description will be given below.

[0063] In this embodiment, the bending mechanism 20 includes a plurality of movable units 200 with channels in series, wherein the angle between two adjacent movable units is variable along any direction and the channels of the two are connected, so that the bending mechanism 20 Bending can take place as a whole and keep the channel clear along the extension direction of the bending mechanism 20 . The outer tube 10 surrounds the bending mechanism 20 in a circumferential direction, and changes in shape as the shape of the bending mechanism 20 changes. In a preferred implementation of this emb...

Embodiment 2

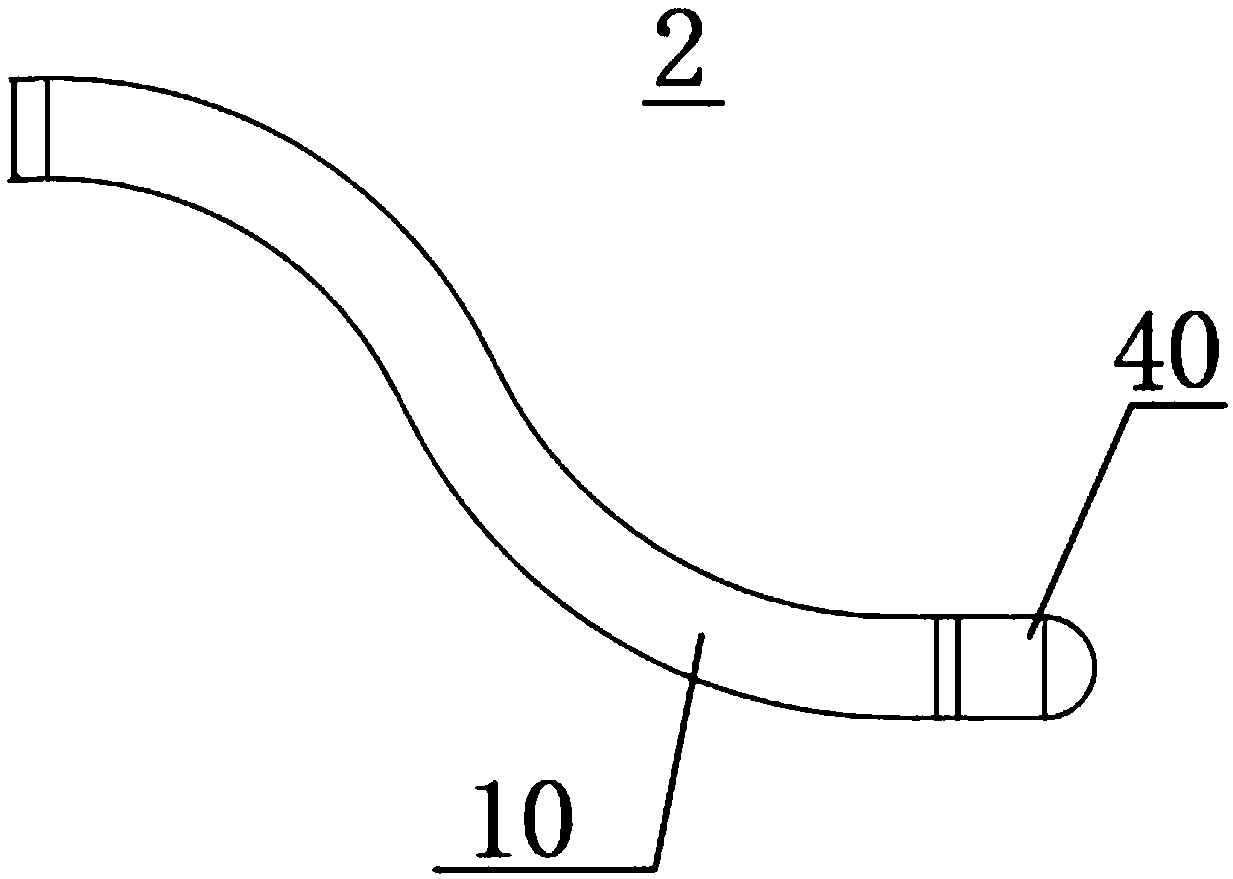

[0071] Figure 2A It is a schematic diagram of the appearance of a medical tube according to Embodiment 2 of the present invention, Figure 2B yes Figure 2A A schematic diagram of the internal structure of the medical tube shown. refer to Figure 2A with Figure 2B , the medical tube 2 may have any one or more of the following structures in addition to the outer tube 10 and the bending mechanism 20 .

[0072] Optionally, in an implementation of this embodiment, the movable unit a at the outlet end and / or the movable unit b at the inlet end of the bending mechanism 20 may be fixedly connected to the outer tube 10; in another embodiment of the present embodiment In the implementation manner, a stopper can be provided at the outlet end and / or the inlet end of the outer tube 10, for example, the stopper X1 (for example, can be a snap ring) arranged at the outlet end and the stopper arranged at the inlet end as shown X2. The limiters are preferably arranged at both ends of t...

Embodiment 3

[0078] Figure 3A It is a schematic diagram of the appearance of a medical tube according to Embodiment 3 of the present invention, Figure 3B yes Figure 3A A schematic diagram of the internal structure of the medical tube shown. refer to Figure 3A with Figure 3B , the medical tube 3 may include an inner tube 30 in addition to the structure described in Embodiment 1 or Embodiment 2. The inner tube 30 extends along the channel of each movable unit 200 in the bending mechanism 20 , that is, the inner tube 30 can adapt to the shape change of the bending mechanism 20 and keep the inner tube 30 unblocked for fluid circulation. In a preferred implementation of this embodiment, the inner tube 30 in this embodiment is a flexible inner tube.

[0079] Using the medical tube 3 provided in this embodiment, in addition to having the advantages of the medical tube 1 provided in Embodiment 1, the inner tube 30 is also conducive to the stable and concentrated delivery of the fluid.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com