Preparation method for marten hair-simulating shell fabric

A production method and fabric technology, applied in the processing of textile materials, manufacturing tools, elongation of fabrics, etc., can solve the problems of softness, bulkiness, poor smoothness, color and feel that are far from real wool, imitation mink. Wool fabrics have problems such as weak thick feeling, etc., to achieve the effect of strong thick feeling, high degree of automation and consistent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Embodiment: a kind of manufacture method of imitation mink wool fabric of this example is characterized in that described method comprises:

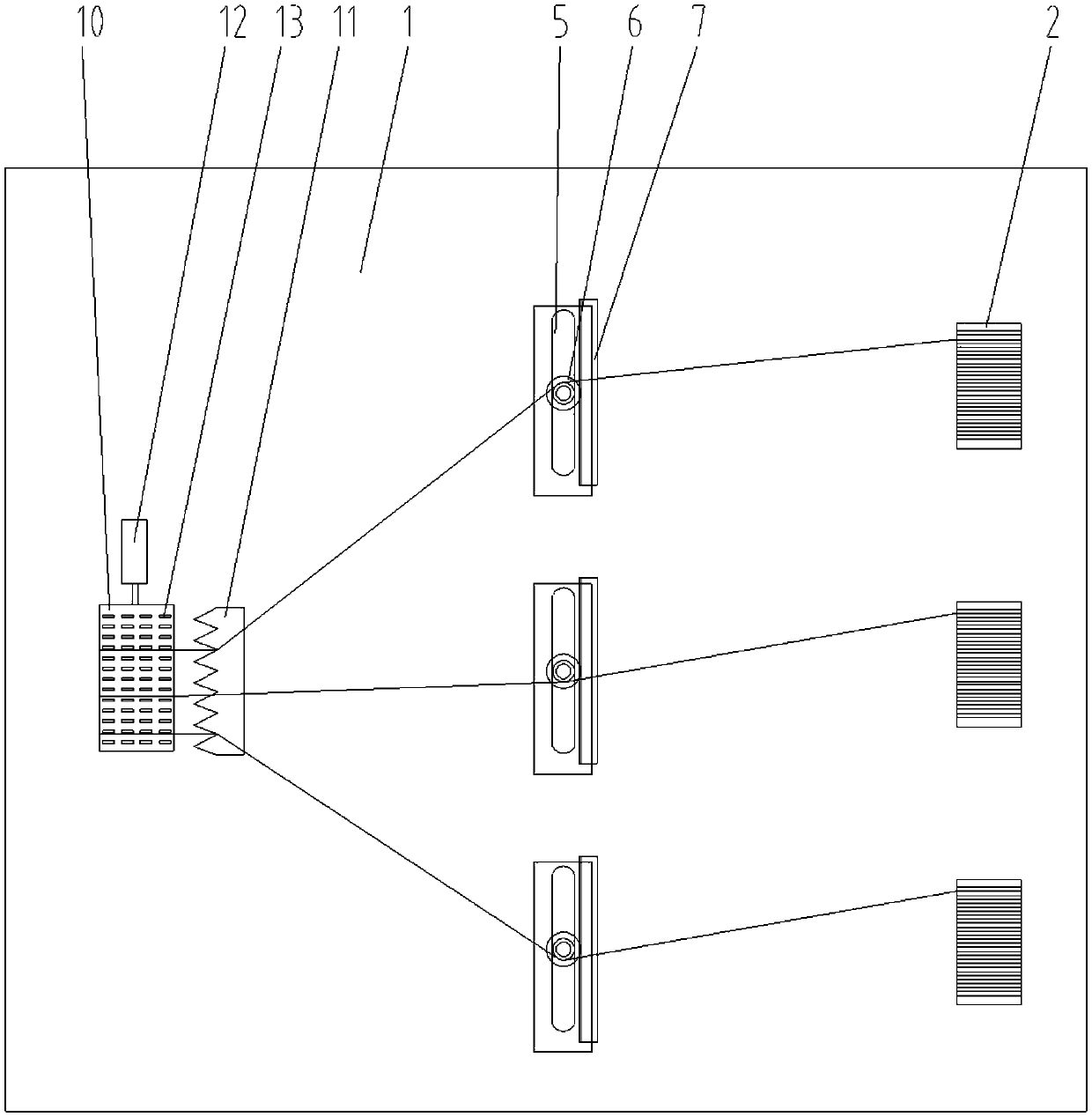

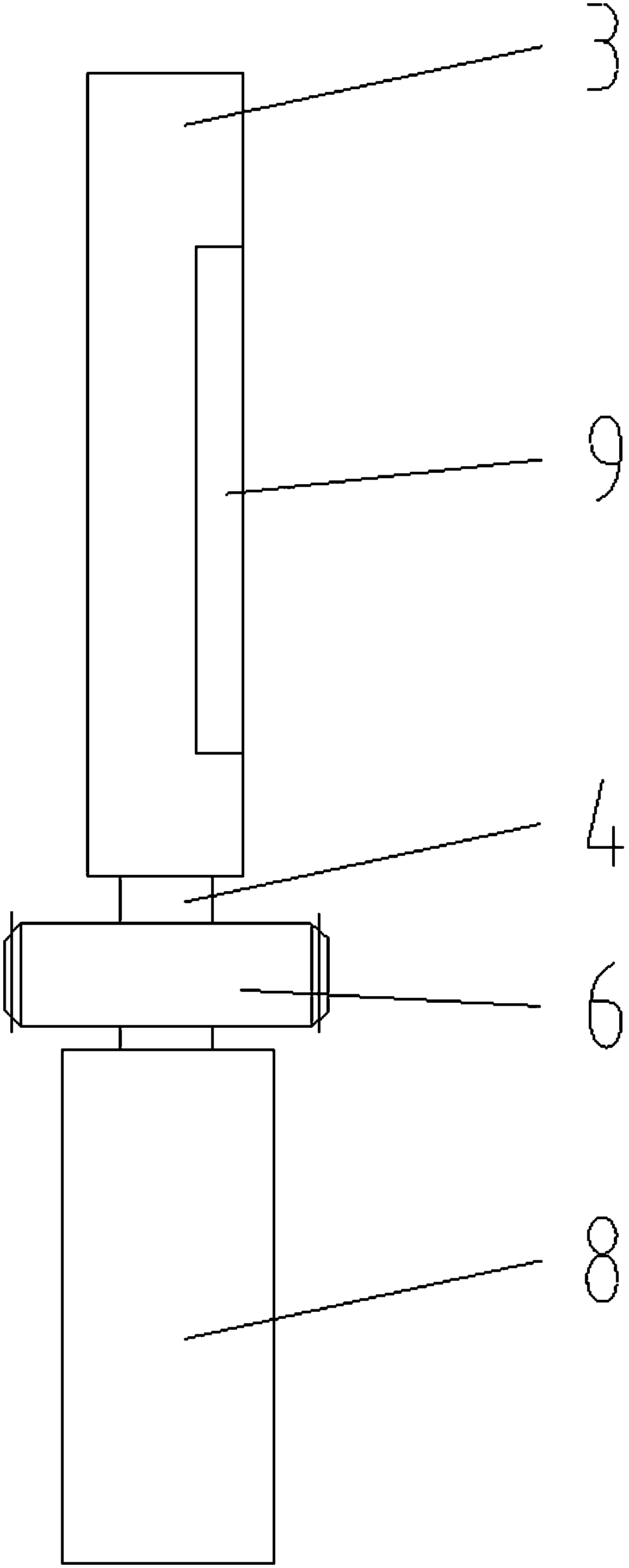

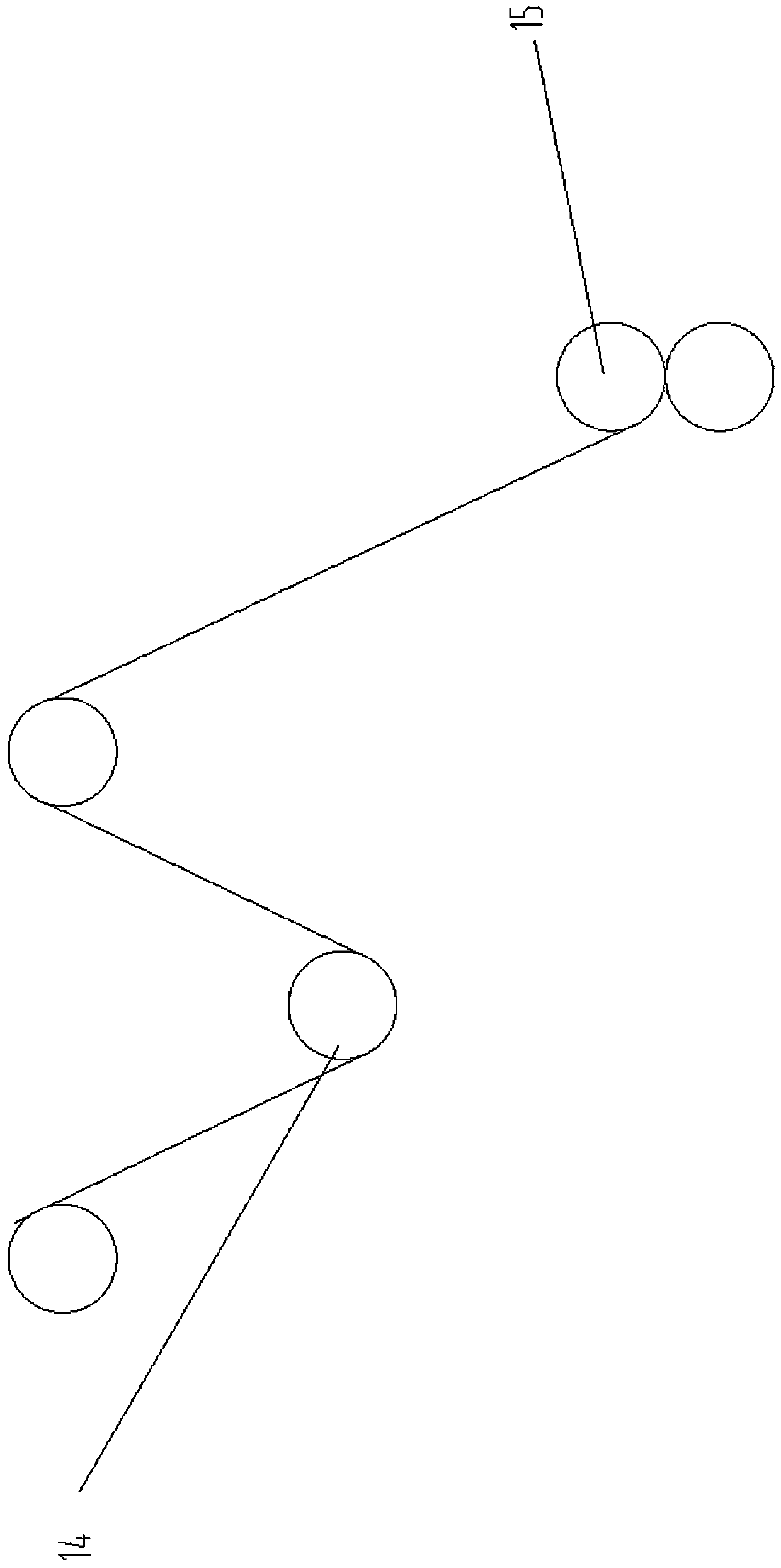

[0034] a. Warp the velvet yarn and bottom yarn on the warping mechanism, then use the warp knitting mechanism to weave, and finally obtain the gray cloth after cutting the width and inspecting the cloth; the warping mechanism is as follows: figure 1 , including a warping frame 1, a number of yarn feeding reels 2 are provided on the warping frame, and a yarn management roller 3 is provided at the exit direction of the yarn feeding reels, such as figure 2 , the spinning roller is fixed with a rotating shaft 4, the rotating shaft is connected in the chute 5, the lower part of the rotating shaft is connected with a gear 6, the gear is meshed with a rack 7, the rotating shaft is connected with the yarn management motor 8, and the yarn management roller is provided with a pressure sensor 9, The pressure sensor is connected to the yarn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com