Yarn winding machine

A winder and yarn technology, applied in the field of yarn processing, can solve the problems of long working hours, large batches, low efficiency, etc., and achieve the effects of saving time, facilitating processing and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

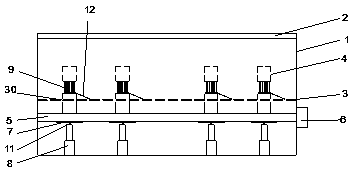

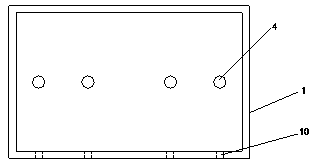

[0020] The invention as Figure 1-3 Shown, comprise box body 1, described box body is provided with dividing plate 3, and described dividing plate is evenly provided with a plurality of through holes 30, and described through hole is provided with winding shaft 4, and described moving around shaft is located at inside the through hole;

[0021] The bottom of the partition in the box is provided with a horizontally arranged worm 5, the outside of the box is provided with a motor 6 for driving the worm 5, and the bottom of the shaft is provided with a worm wheel 7, and the worm meshes with the worm ,

[0022] The lower part of the winding shaft is provided with a lifting rod 8, and the lifting rod is an electric push rod or a hydraulic cylinder, which can reliably support the winding shaft;

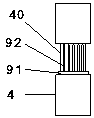

[0023] A chute 40 is provided on the winding shaft, and a flexible retaining ring is movable in the chute, and the flexible retaining ring includes an annular body and some branches, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com