Brush printing film making device and nano film printing method based on the same

A printing method and nano-film technology, applied in the manufacture of microstructure devices, nanotechnology, nanotechnology, etc., can solve the problems of uneven force, large liquid consumption, and inability to brush the film over a long distance, to ensure uniformity and adaptability. Sex-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

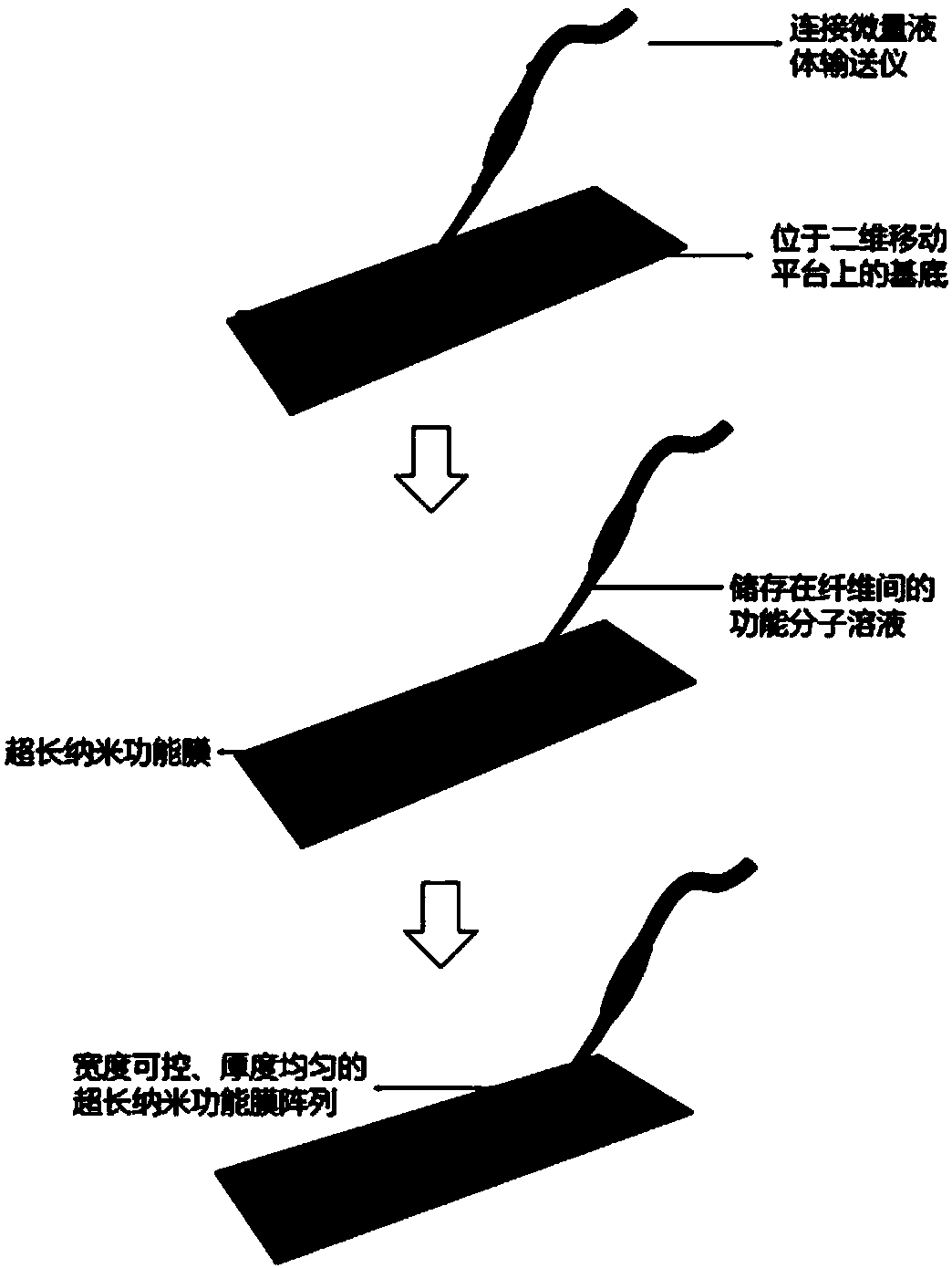

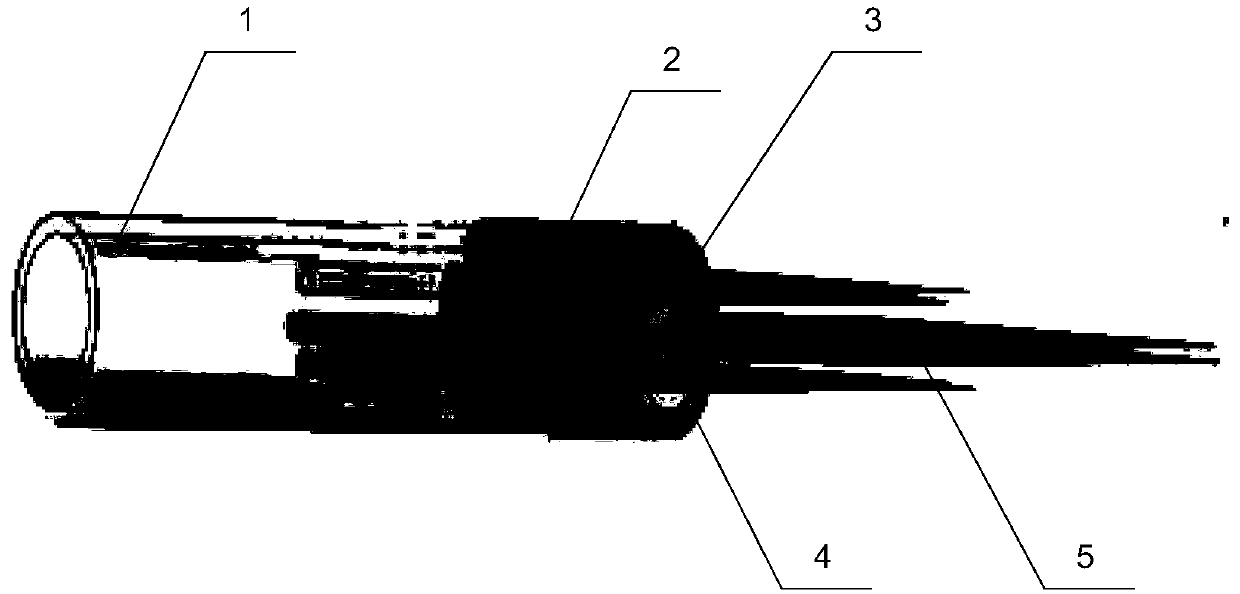

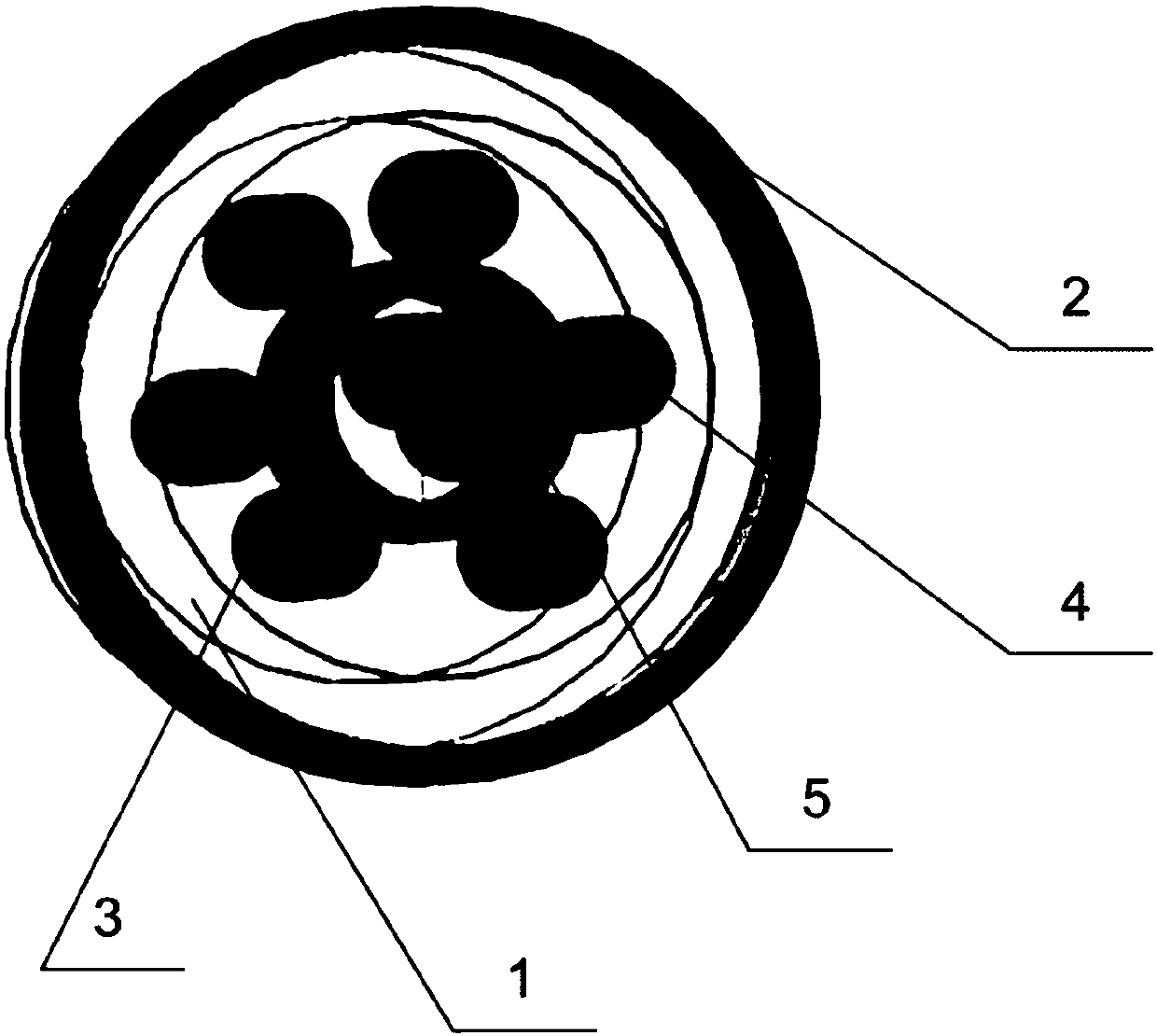

[0051] refer to Figure 1-Figure 4 , Divide the two wolf hairs into two parts and fix them on the opposite inner wall of the inner liquid supply pipe through the double hair fixing point on the inner liquid supply pipe, so that the distance between the tips of the two wolf hairs and the head of the inner liquid supply pipe 11mm, so that the protruding brush hairs are close together at the tip, and 250 wolf hairs are fixed on the outer wall of the inner liquid supply tube as liquid storage hairs, so that the distance between the tip of the liquid storage hairs and the head of the inner liquid supply tube is 10mm, and the outer wall of the liquid storage hair Install the outer liquid supply pipe, and then fix the outer liquid supply pipe and the inner liquid supply pipe with liquid storage hairs and protruding brush bristles through the fastening tube, and the diameters of the liquid storage hairs and protruding brush hairs are both ≤ 100 μm. The prepared brush device was ultras...

Embodiment 2

[0053] refer to figure 1 with figure 2 Divide 10 chemical cilia into two parts and fix them on the opposite inner wall of the inner liquid supply pipe through the double-hair fixing point on the inner liquid supply pipe, so that the distance between the tip of the 10 chemical cilia and the head of the inner liquid supply pipe is 17mm, Make the chemical cilia intersect and close together at the tip, fix 300 wolf hairs on the outer wall of the inner liquid supply pipe as liquid storage hairs, make the distance between the tip of the liquid storage hairs and the head of the inner liquid supply pipe 15mm, and put them on the outer wall of the liquid storage hair coat. The liquid supply pipe, and the outer liquid supply pipe and the inner liquid supply pipe fixed with liquid storage hairs and protruding brush hairs are fixed by fastening tubes, and the diameters of the liquid storage hairs and protruding brush hairs are both ≤ 100 μm. The prepared brush device was ultrasonically ...

Embodiment 3

[0055] refer to figure 1 with figure 2 , Divide the 6 stone badger hairs into two parts, and fix them on the opposite inner wall of the inner liquid supply pipe through the double hair fixing points on the inner liquid supply pipe, so that the distance between the tips of the six stone badger hairs and the head of the inner liquid supply pipe is 4mm , so that the stone badger hairs are close together at the tip, and 5 stone badger hairs are fixed on the outer wall of the inner liquid supply pipe as liquid storage hairs, so that the distance between the tip of the liquid storage hairs and the head of the inner liquid supply pipe is 4mm, and the outer wall of the liquid storage hair The liquid supply pipe, and the outer liquid supply pipe and the inner liquid supply pipe fixed with liquid storage hairs and protruding brush hairs are fixed by fastening tubes, and the diameters of the liquid storage hairs and protruding brush hairs are both ≤ 100 μm. The prepared brush printing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com