High-efficiency continuous machine tea refining automation production line

A technology of automatic production line and continuous machine, applied in the direction of tea processing before extraction, can solve the problems of inability to automatically configure process parameters, difficult tea quality, low level of standardization and intelligence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

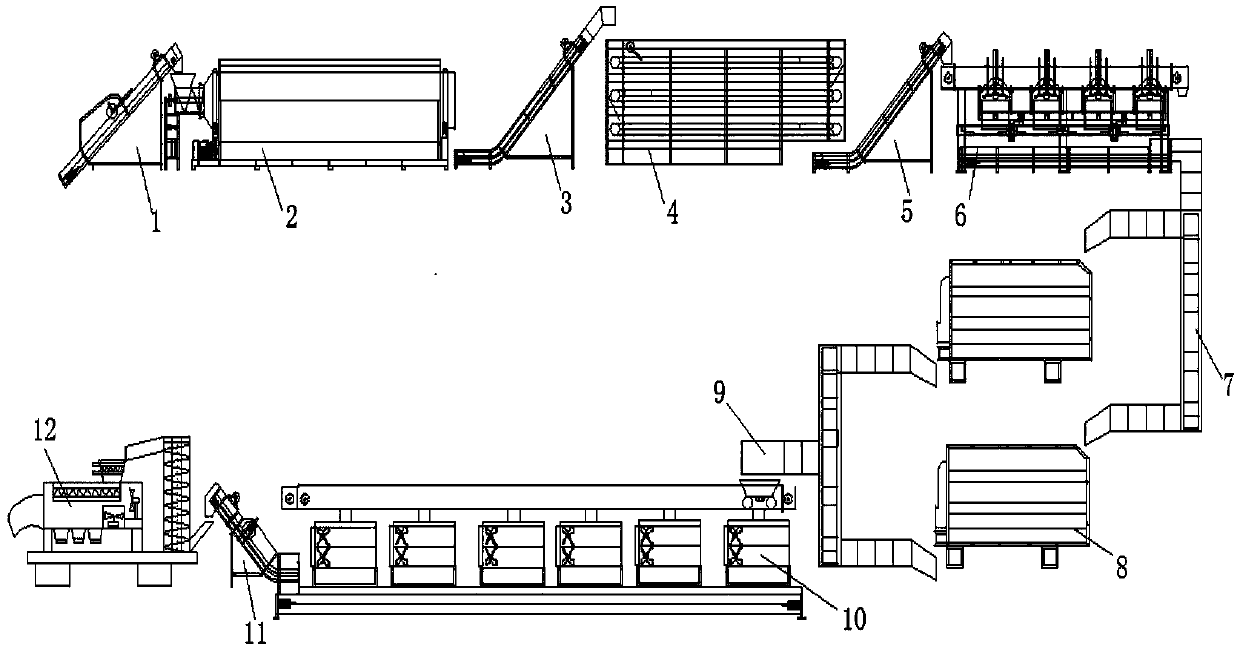

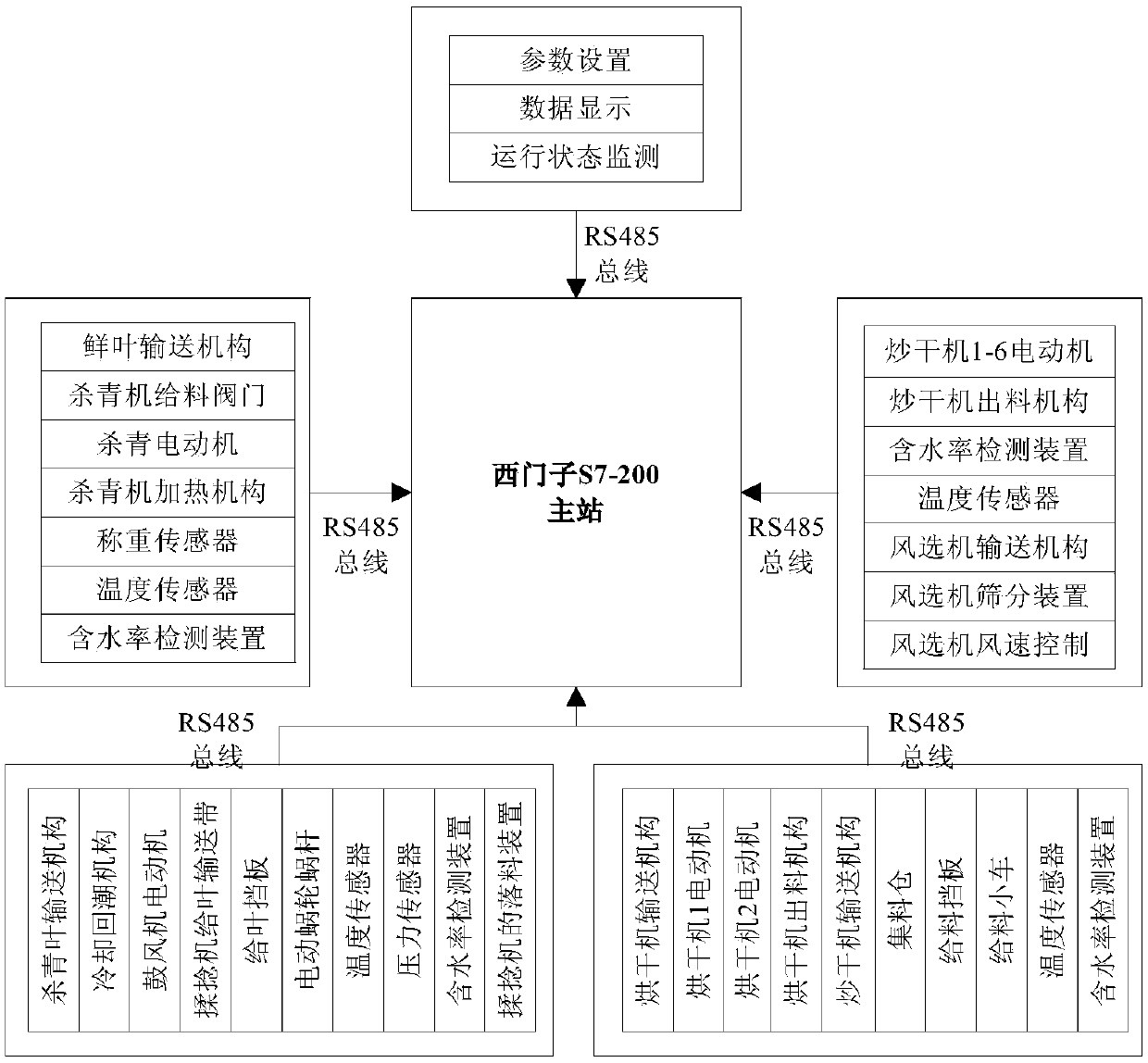

[0026] Such as figure 1 As shown, the mechanical parts of the whole machine-picked tea refining production line are composed of fresh leaf conveying mechanism 1, greening machine 2, greening leaf conveying mechanism 3, cooling and moisture regaining machine 4, kneading machine to leaf conveying mechanism 5, four-machine linkage kneading machine 6, drying Dryer feeding and conveying mechanism 7, drying machine 8, frying and drying machine feeding and conveying mechanism 9, frying and drying machine 10, winnowing machine feeding and conveying mechanism 11, winnowing machine 12, tea leaves are graded in the process of processing Conveying, fresh leaves first enter the degreening machine 2, then enter the cooling and dampening machine 3, rolling machine 6, drying machine 8, frying and drying machine 10, and finally enter the winnowing machine 12. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com