A kind of preparation method of silver sheet for fuse

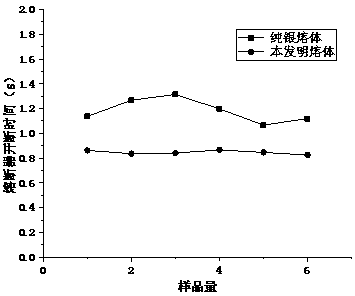

A technology of fuses and silver sheets, which is used in the manufacture of fuses, emergency protection devices, electrical components, etc., can solve the problem that the circuit overload protection cannot be well realized, the cost of electrical products remains high, and the arc-extinguishing ability of pure silver materials is weak. and other problems, to achieve the effect of reducing the breaking time of fault current, reducing the filling of arc extinguishing medium, and excellent self-extinguishing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

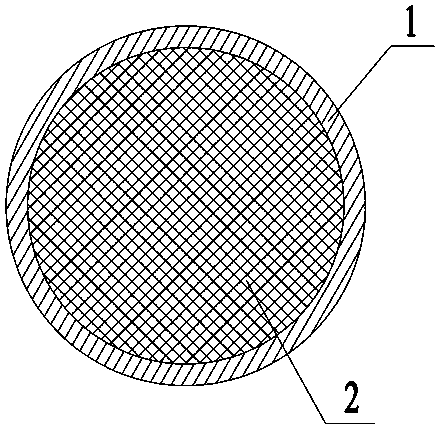

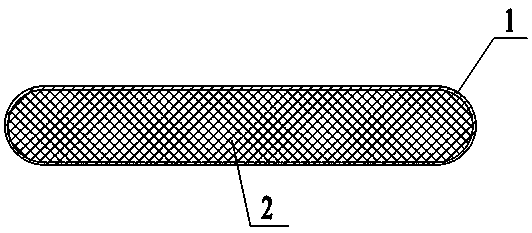

[0028] A method for preparing a silver sheet for a fuse, comprising silver alloy 1 in the outer layer and pure silver 2 in the core, the pure silver material in the core has good electrical conductivity and undertakes the conductive function of the circuit, and the silver alloy in the outer layer is mainly responsible for arc extinguishing and The function of reducing the melting point of the molten material; the silver alloy includes the following raw materials in mass percentage: 5% CdO powder, 1% Ni powder, 94% silver-copper alloy powder, wherein the purity of the pure silver is 99.99%; The silver-copper alloy powder is mixed by Ag and Cu at a mass ratio of 72:28. Cu and Ag are smelted to form the eutectic material Ag72Cu. The alloy material has a lower melting point than pure silver and good fluidity. It melts first when overloaded. The metallurgical effect is used to wrap the pure silver melt in the core, and the silver and copper penetrate into each other to form a silver...

Embodiment 2

[0038] A method for preparing a silver sheet for a fuse, comprising silver alloy 1 in the outer layer and pure silver 2 in the core, the pure silver material in the core has good electrical conductivity and undertakes the conductive function of the circuit, and the silver alloy in the outer layer is mainly responsible for arc extinguishing and The function of reducing the melting point of the melt material; the silver alloy includes the following raw materials in mass percentage: 10% CdO powder, 2.5% Ni powder, 87.5% silver-copper alloy powder, wherein the purity of the pure silver is 99.99%; The silver-copper alloy powder is mixed with Ag and Cu at a mass ratio of 72:28. Cu and Ag are smelted to form a eutectic material Ag72Cu. The alloy material has a lower melting point than pure silver and good fluidity. It melts first when overloaded. Metallurgical effects are used to wrap the pure silver melt in the core, and silver and copper penetrate each other to form a silver-copper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com