A preparation method of free-cutting high-strength multi-phase non-quenched and tempered steel

A non-quenched and tempered steel, high-strength technology, applied in the field of high-strength multi-phase non-quenched and tempered steel preparation, can solve the problems of low mechanical properties, adverse effects on performance, and easy to become a source of cracks, etc., to achieve obvious microstructure grain refinement, Improve tissue uniformity, the effect of tissue uniformity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

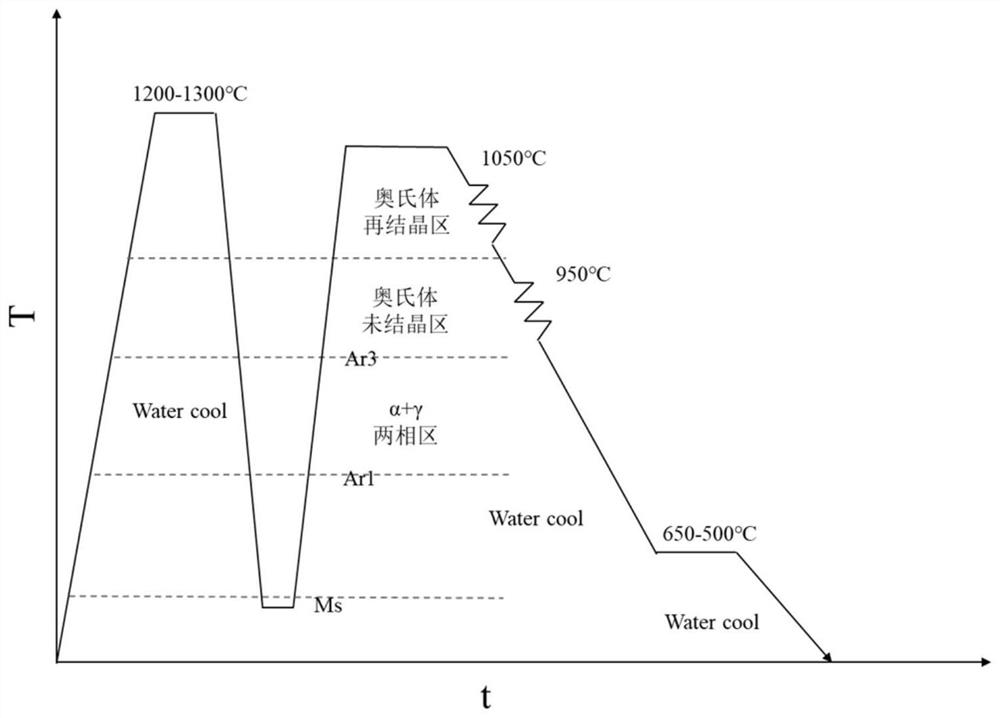

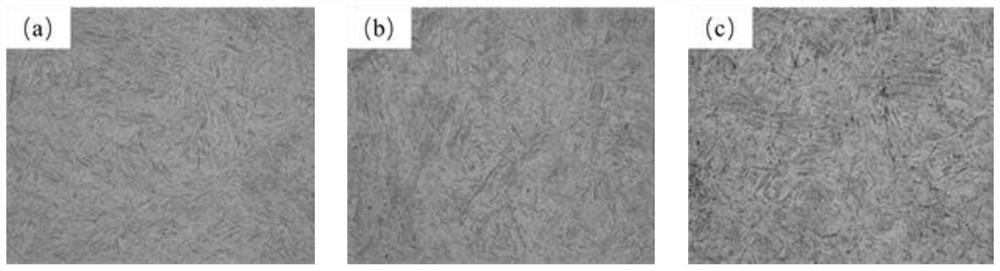

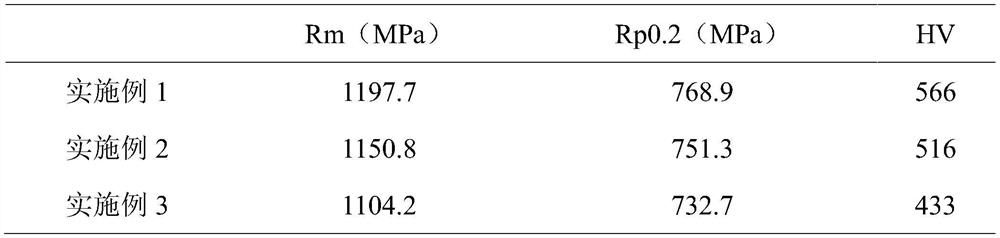

[0017] Example 1: Non-quenched and tempered steel FAS2225, in the pre-heat treatment, the tapping temperature is 1220℃, ultra-fast water cooling to 248℃ by water cooling equipment, the method proposed in the present invention is used for rolling, the thickness of the slab is 110mm, and the slab thickness is 110mm. ℃, heat preservation for 25min, rapid cooling through water cooling device to remove surface oxide scale, preliminary rolling at 1045℃, final rolling (finishing) temperature of 946℃. After water cooling, the upper cooling bed temperature is 598℃, and finally the water is cooled to room temperature.

example 2

[0018] Example 2: Non-quenched and tempered steel FAS2225, in the pre-heat treatment, the tapping temperature is 1260℃, it is ultra-fast water cooled to 327℃ by water cooling equipment, and the method proposed by the present invention is used for rolling. The thickness of the slab is 110mm, and the slab thickness is 110mm. ℃, heat preservation for 30min, rapid cooling through water cooling device to remove surface oxide scale, preliminary rolling at 1048℃, and final rolling (finishing) temperature of 937℃. After water cooling, the upper cooling bed temperature is 628℃, and finally the water is cooled to room temperature.

example 3

[0019] Example 3: Non-quenched and tempered steel FAS2225, in the pre-heat treatment, the tapping temperature is 1250℃, ultra-fast water cooling to 362℃ by water cooling equipment, and the method proposed in the present invention is used for rolling, the slab thickness is 110mm, and the slab thickness is 110mm. ℃, heat preservation for 30min, rapid cooling by water cooling device to remove surface oxide scale, preliminary rolling at 1052℃, final rolling (finishing) temperature of 953℃. After water cooling, the upper cooling bed temperature is 581℃, and finally water cooling to room temperature.

[0020] Table 1 Mechanical properties

[0021]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com