Separation system of saturated hydrocarbon cracking gas and utilization method of rich ethane/propane saturated hydrocarbon

A separation system and hydrocarbon cracking technology, applied in the field of saturated resource utilization in refineries, can solve the problems of low investment recovery rate, waste, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

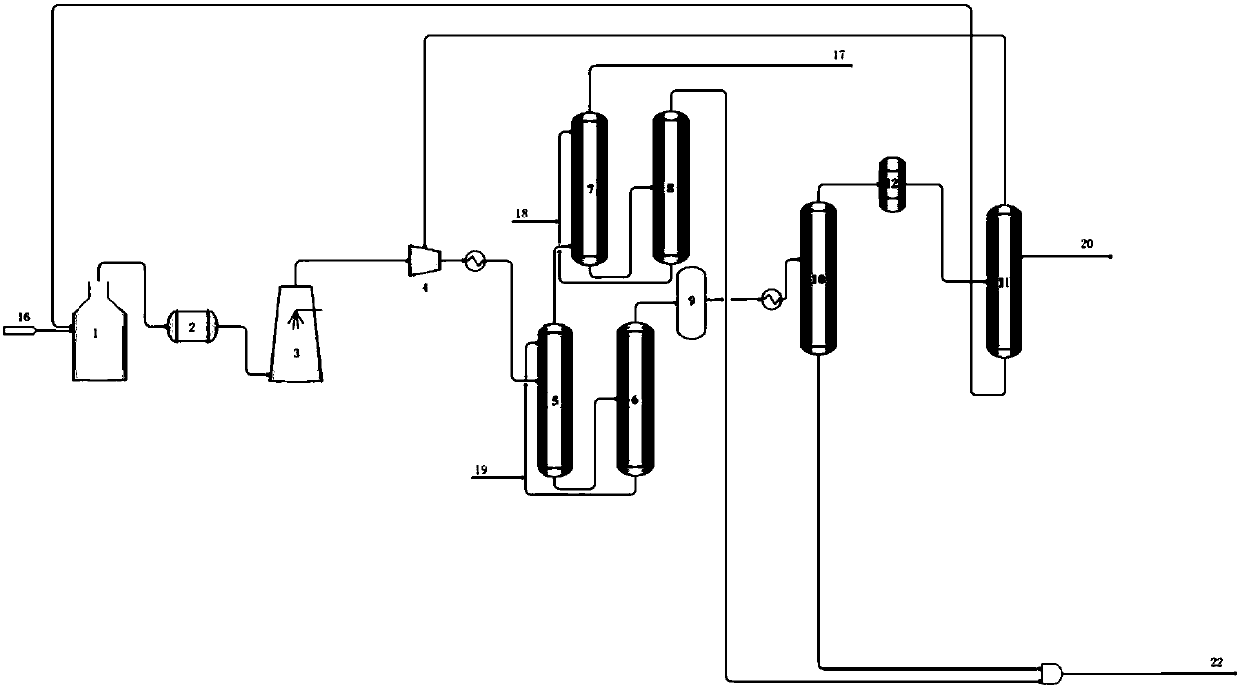

[0069] use as figure 1 A saturated hydrocarbon cracking gas separation system shown includes: cracking furnace 1, waste heat boiler 2, quenching water tower 3, compressor 4, absorption tower 5, desorption tower 6, reabsorption tower 7, gasoline stabilization tower 8, drying tower 9. Deethanizer 10, ethylene rectification tower 11, C2 hydrogenation reactor 12.

[0070] The pyrolysis furnace 1 is connected to the waste heat boiler 2, the quenching water tower 3, and the compressor 4 successively to the middle part of the absorption tower 5, the top of the absorption tower 5 is connected to the reabsorption tower 7, and the tower kettle is connected to the desorption tower 6; The kettle is connected to the gasoline stabilization tower 8, the top of the gasoline stabilization tower 8 is connected to the liquefied gas production line, and the tower kettle is connected to the top of the reabsorption tower 7; the top of the desorption tower 6 is connected to the drying tower 9 and t...

Embodiment 2

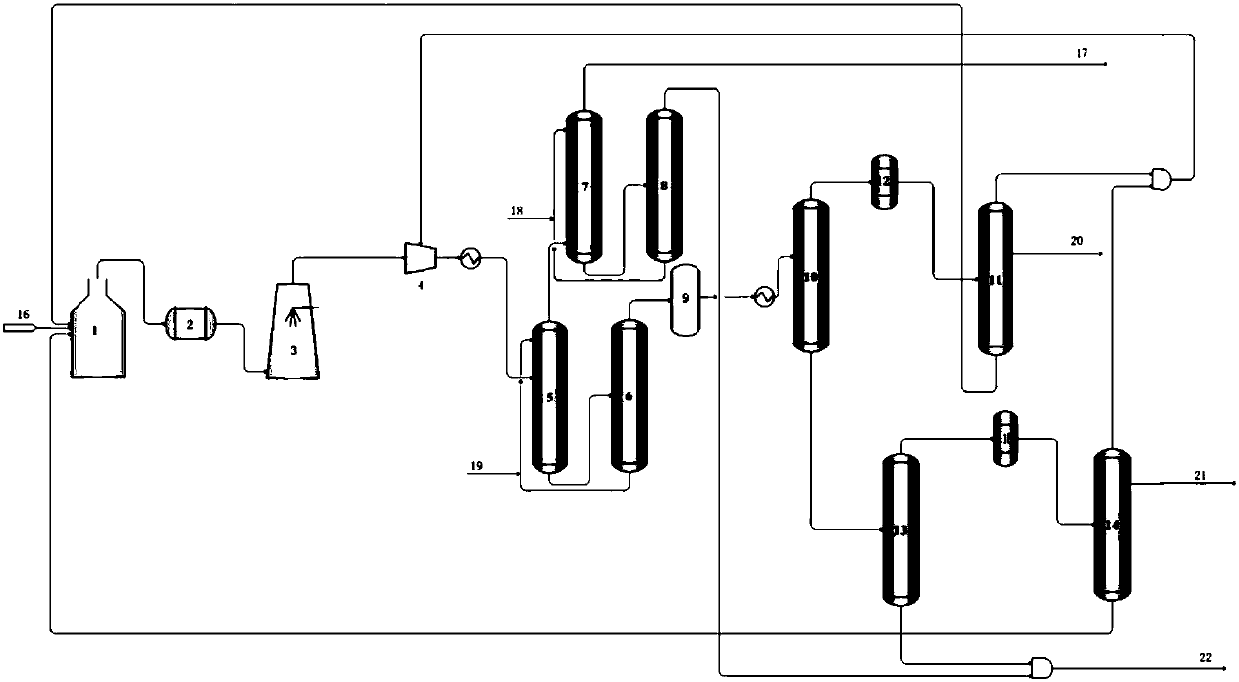

[0089] use as figure 2 A saturated hydrocarbon cracking gas separation system shown includes: cracking furnace 1, waste heat boiler 2, quenching water tower 3, compressor 4, absorption tower 5, desorption tower 6, reabsorption tower 7, gasoline stabilization tower 8, drying tower 9. Deethanizer 10, ethylene rectification tower 11, C2 hydrogenation reactor 12, depropanizer 13, propylene rectification tower 14, C3 hydrogenation reactor 15.

[0090]The pyrolysis furnace 1 is connected to the waste heat boiler 2, the quenching water tower 3, and the compressor 4 successively to the middle part of the absorption tower 5, the top of the absorption tower 5 is connected to the reabsorption tower 7, and the tower kettle is connected to the desorption tower 6; The kettle is connected to the gasoline stabilization tower 8, the top of the gasoline stabilization tower 8 is connected to the liquefied gas production line, and the tower kettle is connected to the top of the reabsorption tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com