Seepage-proofing and air-permeable sand with super-hydrophobicity and high durability and preparation method of seepage-proofing and air-permeable sand

A super-hydrophobic and air-permeable sand technology, which is applied in the field of environmental engineering, can solve the problems of poor anti-seepage effect, poor durability, and easy adhesion of the surface of anti-permeation air sand, so as to improve the long-term effect, improve the impermeability, and improve the preparation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

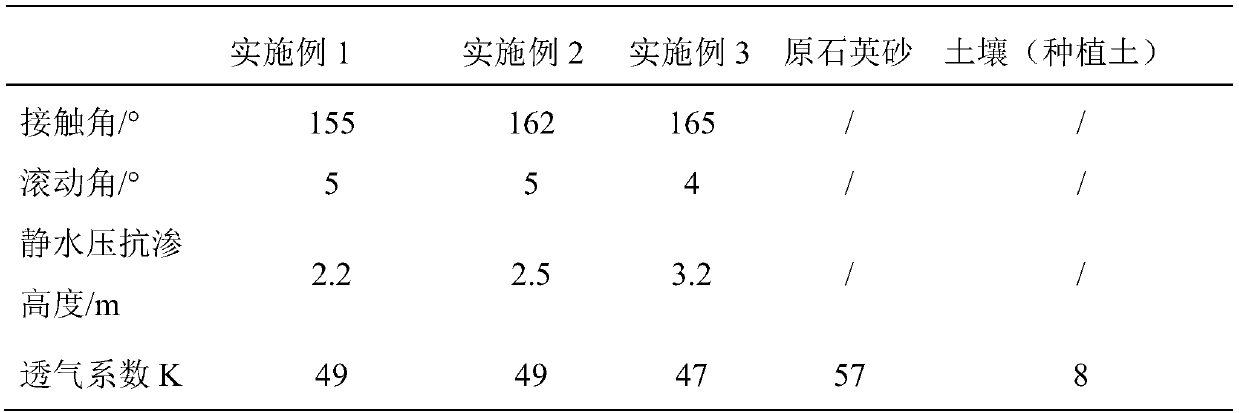

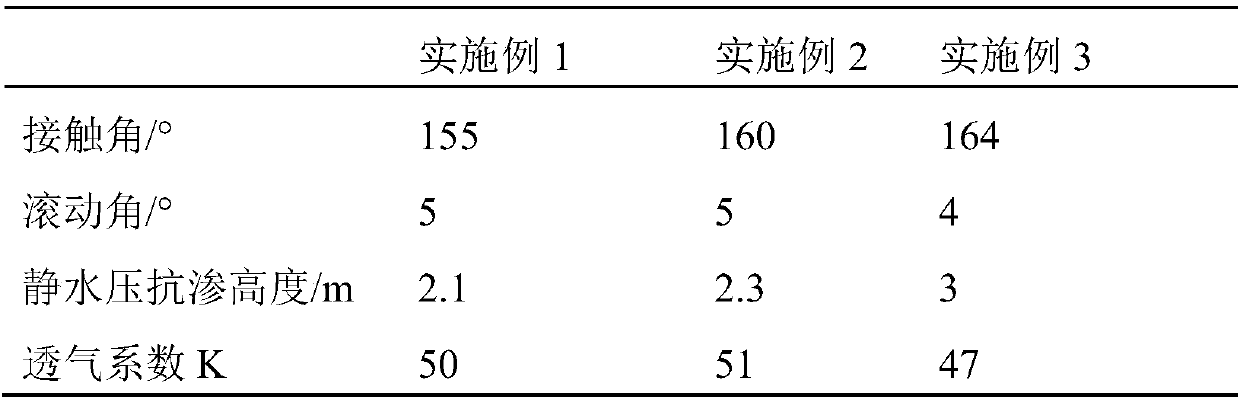

Embodiment 1

[0022] Heat 94 parts of quartz sand to 200°C, remove the moisture on the surface, and let it stand still; when it cools to 90°C, add it to the stirring pot, and add 4 parts of methyl silicone resin and 0.4 parts of diethylenetriamine Stir well; then add 1.2 parts of polytetrafluoroethylene and 0.4 parts of nano-SiO 2 , Stir evenly to produce super-hydrophobic, highly durable anti-permeation air sand.

Embodiment 2

[0024] Heat 93 parts of quartz sand to 180°C, remove the moisture on its surface, and let it stand still; when it cools to 80°C, add it to the stirring pot, and add 4 parts of phenolic resin and 0.4 parts of hexamethylenetetramine Stir well; then add 2 parts of polytetrafluoroethylene and 0.6 parts of nano-SiO 2 , Stir evenly to produce super-hydrophobic, highly durable anti-permeation air sand.

Embodiment 3

[0026] Heat 92 parts of quartz sand to 170°C, remove the moisture on the surface, and let it stand; when it cools to 70°C, add it to the stirring pot, and add 4.5 parts of polyamide modified epoxy resin and 0.45 parts of ethyl alcohol Stir the diamine evenly; then add 2.4 parts of polytetrafluoroethylene and 0.65 parts of nano-SiO 2 , Stir evenly to produce super-hydrophobic, highly durable anti-permeation air sand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com