Preparation method of hollow carbon nanosphere

A technology of nanospheres and hollow carbon, which is applied in nanocarbon, nanotechnology, nanotechnology, etc., can solve the problems of complex preparation process, poor repeatability, and difficult control of parameters, and achieve the effect of simple preparation method, regular structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1 A preparation method of hollow carbon nanospheres

[0038] This embodiment is a preparation method of hollow carbon nanospheres, which is carried out in sequence according to the following steps:

[0039] (11) Disperse 0.8 kg of acorn kernel powder with a particle size of 5-10 μm in distilled water to form solution A1, dissolve 1.0 kg of nickel acetate in distilled water to form solution B1, slowly drop solution B1 into solution A1, and stir vigorously 1h, forming solution C1;

[0040] (12) Slowly add an aqueous solution containing 0.3kg of potassium hydroxide dropwise to solution C1, stir vigorously for 30 minutes (rotation speed: 500r / min), heat and evaporate at 85°C to remove water, and obtain product D1;

[0041] (13) Put the product D1 in a closed reactor, calcinate at 700°C for 2 hours, and cool it down to room temperature naturally after the reaction, to obtain the product E1;

[0042] (14) Wash the product E1 with distilled water to neutrality to obt...

Embodiment 2-5

[0046] The preparation method of embodiment 2-5 hollow carbon nanosphere

[0047]Examples 2-5 are a preparation method of hollow carbon nanospheres, the preparation steps are similar to those of Example 1, the only difference is that the corresponding technical parameters in the preparation process are different, as shown in the following table.

[0048]

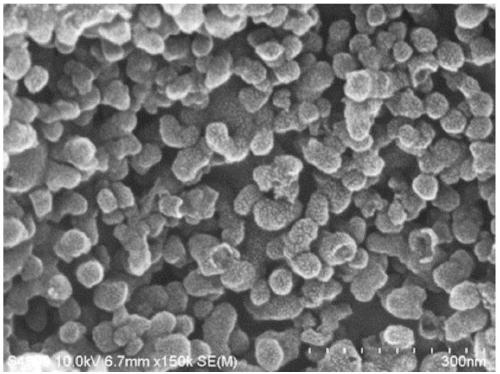

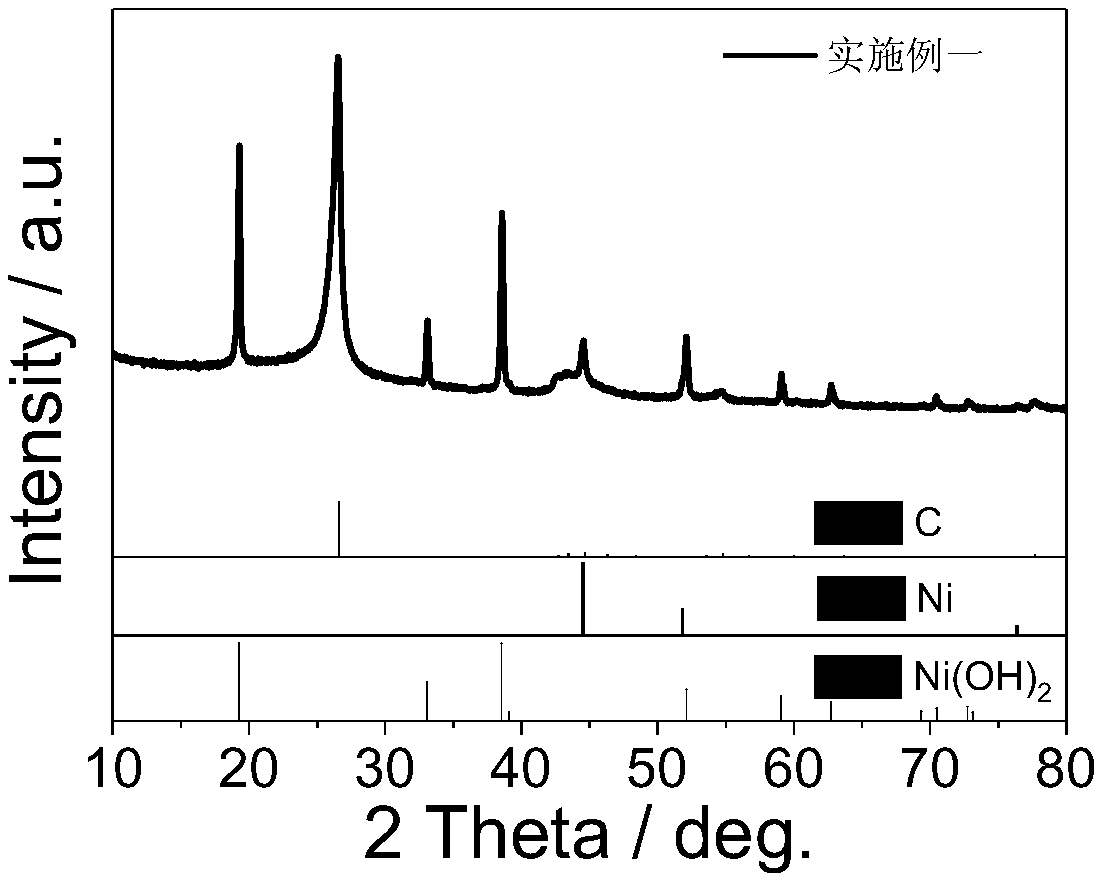

[0049] SEM, TEM and XRD tests of the hollow carbon nanospheres prepared in Examples 2-5 show that the prepared hollow carbon nanospheres have a uniform structure and a porous structure.

Embodiment 6

[0050] Example 6 Effects of different carbon sources on the properties of hollow carbon nanospheres

[0051] The choice of carbon source has a great influence on the formation process of hollow carbon nanospheres. In order to explore the influence of different carbon sources on the properties of hollow carbon nanospheres, this example carried out experiments on different carbon sources. The preparation process of hollow carbon nanospheres and Example 1 is similar, except that the carbon source is different, as follows.

[0052] Group A: the acorn kernel powder provided by embodiment 1;

[0053] Group B: glucose;

[0054] Group C: corn starch;

[0055] Group D: licorice residue.

[0056]

[0057] It can be seen from the above table that only the acorn kernel powder provided by the present invention can prepare carbon nanospheres with regular structure and uniform particle size. The particle size of the product is 30-50nm, with strong adsorption and large specific surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com