Wood modifying agent with surface activity as well as preparation method and application thereof

A surface-active and modifier technology, applied in wood treatment, wood impregnation, wood impregnation, etc., can solve the problems of single modification effect, discoloration and deformation of wood, etc., and achieve strong hydrophobicity, reduced moisture absorption rate, and good smoke suppression effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a kind of preparation method of the wood modifier with surface activity, comprising the following steps:

[0037] At a temperature of -5 to 5°C, cyanuric chloride and n-octylamine undergo the first substitution reaction in toluene to generate the first intermediate;

[0038] At a temperature of 45-55°C, the first intermediate and γ-aminobutyric acid undergo a second substitution reaction in ethanol to generate a second intermediate;

[0039] At a temperature of 85-95 DEG C, the second intermediate and 3-mercapto-1,2,4-triazole undergo a third substitution reaction in lye to obtain a surface-active wood modifier.

[0040] At the temperature of -5-5°C, cyanuric chloride and n-octylamine undergo the first substitution reaction in toluene to generate the first intermediate.

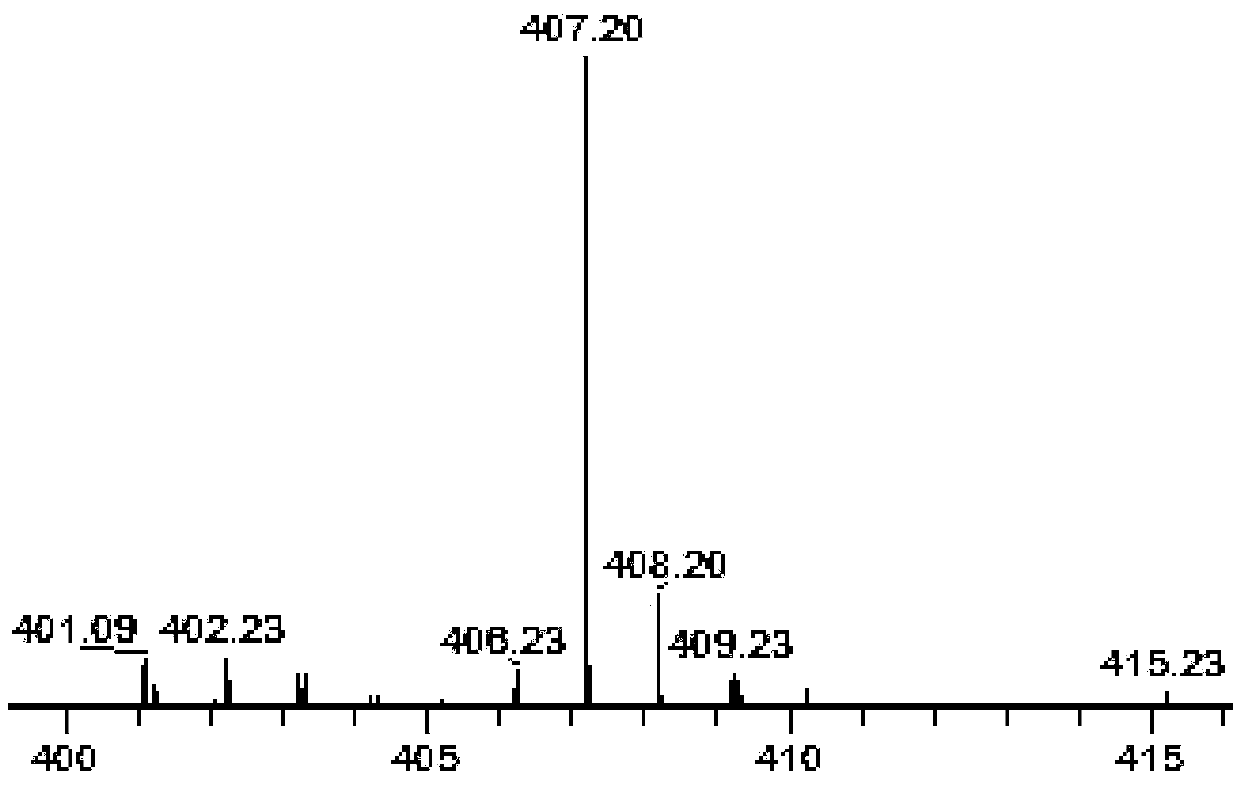

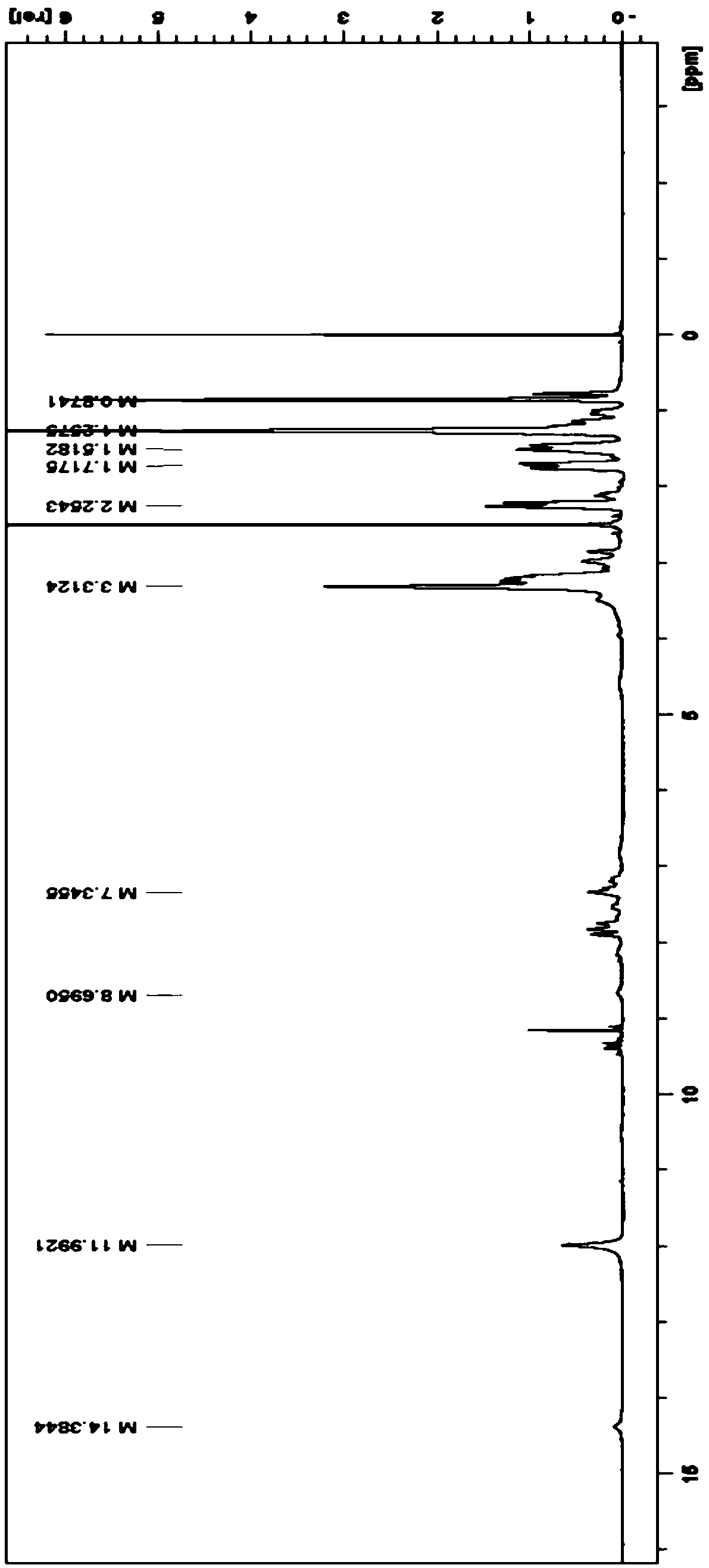

[0041] The reaction process of the first substitution reaction of the present invention is shown in formula (1):

[0042]

[0043] In the present invention, the...

Embodiment 1

[0071] Dissolve 0.1mol cyanuric chloride in 300ml toluene and transfer it to a four-necked bottle, which has been placed in a low-temperature cooling circulation pump at -5°C in advance to ensure that the reaction temperature between cyanuric chloride and n-octylamine is - 5°C. Under the condition of stirring, 100 ml of toluene solution containing 0.5 mol of n-octylamine was slowly dropped into the four-necked flask through a constant pressure dropping funnel, the dropping speed was 2 to 3 seconds / drop, and dissolved in water with sodium hydroxide (0.5 mol / L) solution to maintain the pH of the reaction at 8. The end point of the reaction (that is, the complete disappearance of the point of cyanuric chloride) was monitored by thin-layer chromatography (the developer was toluene:methanol=2:1). After the reaction for 5 hours, the filtrate was placed in a separatory funnel, and the filtrate was obtained by suction filtration under reduced pressure. The filtrate was washed succes...

Embodiment 2

[0089] Dissolve 0.2mol cyanuric chloride in 300ml toluene and transfer it to a four-neck bottle, which has been placed in a low-temperature cooling circulation pump at 0°C in advance to ensure that the reaction temperature between cyanuric chloride and n-octylamine is 0°C . Under the condition of stirring, slowly drop 200ml of toluene solution containing 0.6mol n-octylamine into the four-necked flask through the constant pressure dropping funnel, the dropping speed is 2~3 seconds / drop, and dissolve it with sodium hydroxide (0.5mol / L) solution to maintain the pH of the reaction at 9. The end point of the reaction (that is, the point of cyanuric chloride completely disappears) was monitored by thin-layer chromatography (developing agent: toluene:methanol=4:2). After the reaction for 4 hours, the filtrate was placed in a separatory funnel, and the filtrate was obtained by suction filtration under reduced pressure. The filtrate was washed successively with 0.5 mol / L hydrochloric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total smoke output | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com