Carbon-based ZIF (zeolitic imidazolate framework) composite catalyst as well as preparation method and application thereof in electrocatalytic reduction of carbon dioxide

A composite catalyst and carbon-based technology, applied in the field of electrocatalysis, can solve the problems of not being able to meet the application requirements, not being widely used, and having no catalytic activity, etc., and achieve excellent electrocatalytic carbon dioxide reduction performance, easy promotion, and outstanding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

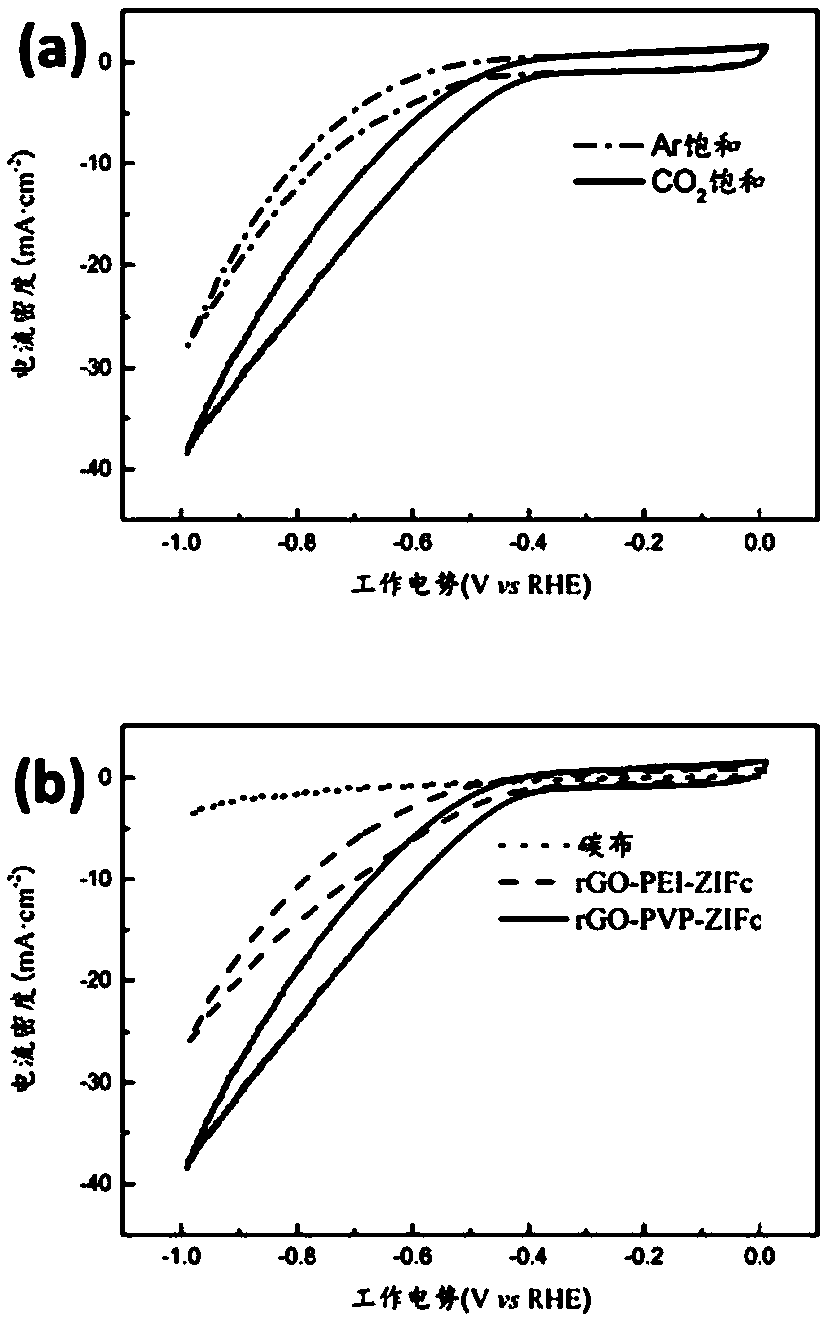

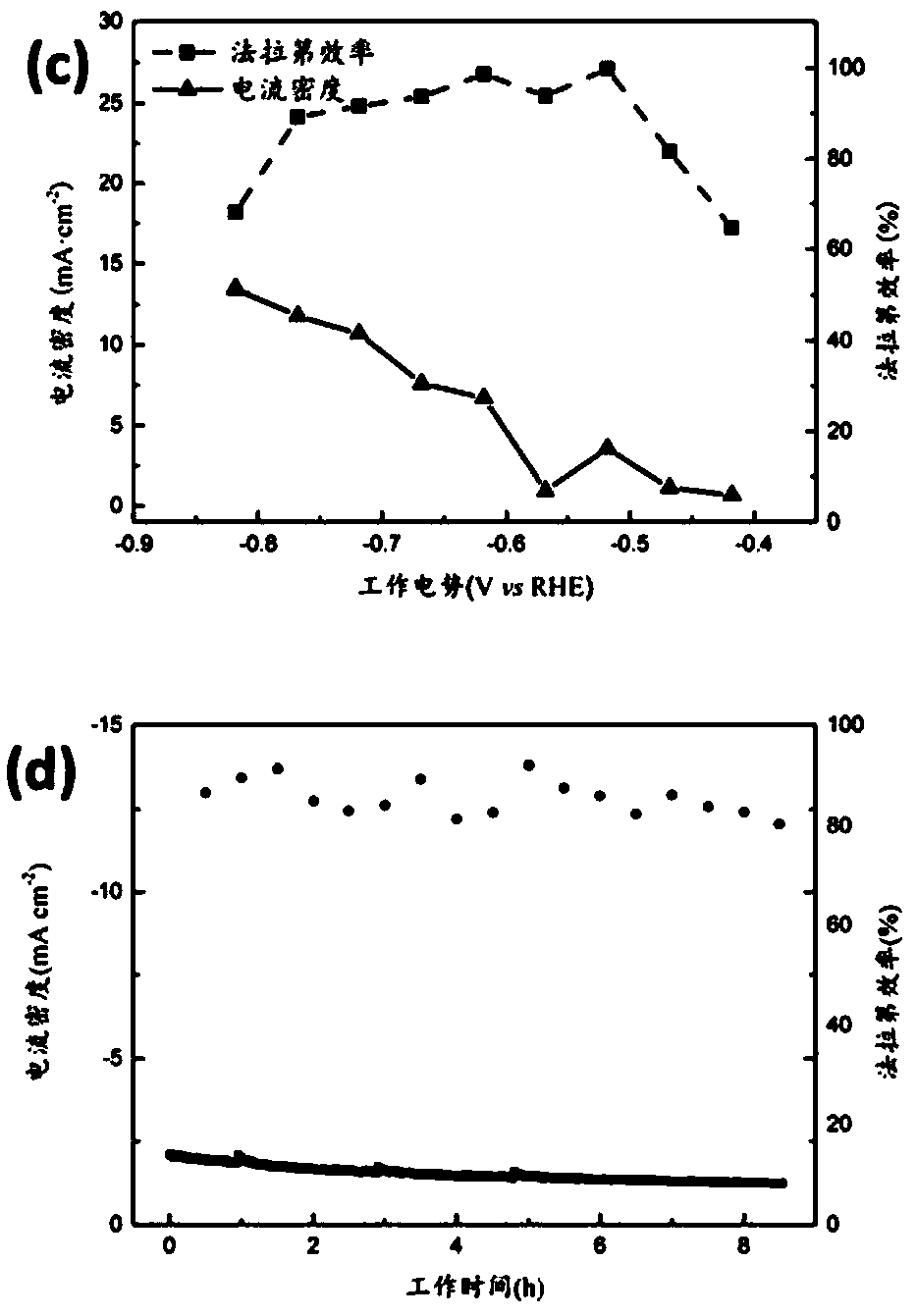

[0029] The present invention selects ZIF as a precursor, uses the method of induced growth to compound it with carbon materials, and then undergoes high-temperature carbonization to form a rich mesoporous pore structure, and constructs an active center of Fe-N-C, which can convert carbon dioxide into carbon monoxide. . In order to realize the efficient catalytic carbon dioxide reduction of the catalyst, the present invention mainly optimizes the catalytic performance of the carbon dioxide reduction by selecting different transition metal salts, different binders and different carbon materials. The present invention combines ZIF with rich pore structure and carbon material to realize high-efficiency catalytic carbon dioxide conversion. The preparation method of carbon-based composite ZIF includes the following three steps: (1) purification and pretreatment of carbon material; (2) carbon dioxide The material and the binder are added to the ZIF precursor solution, and the ZIF is ...

Embodiment 1

[0051] 1. Graphene oxide pretreatment: Wash the prepared graphene oxide with a large amount of 0.1M dilute hydrochloric acid to remove impurities contained therein, and then wash it with a large amount of water until it is nearly neutral;

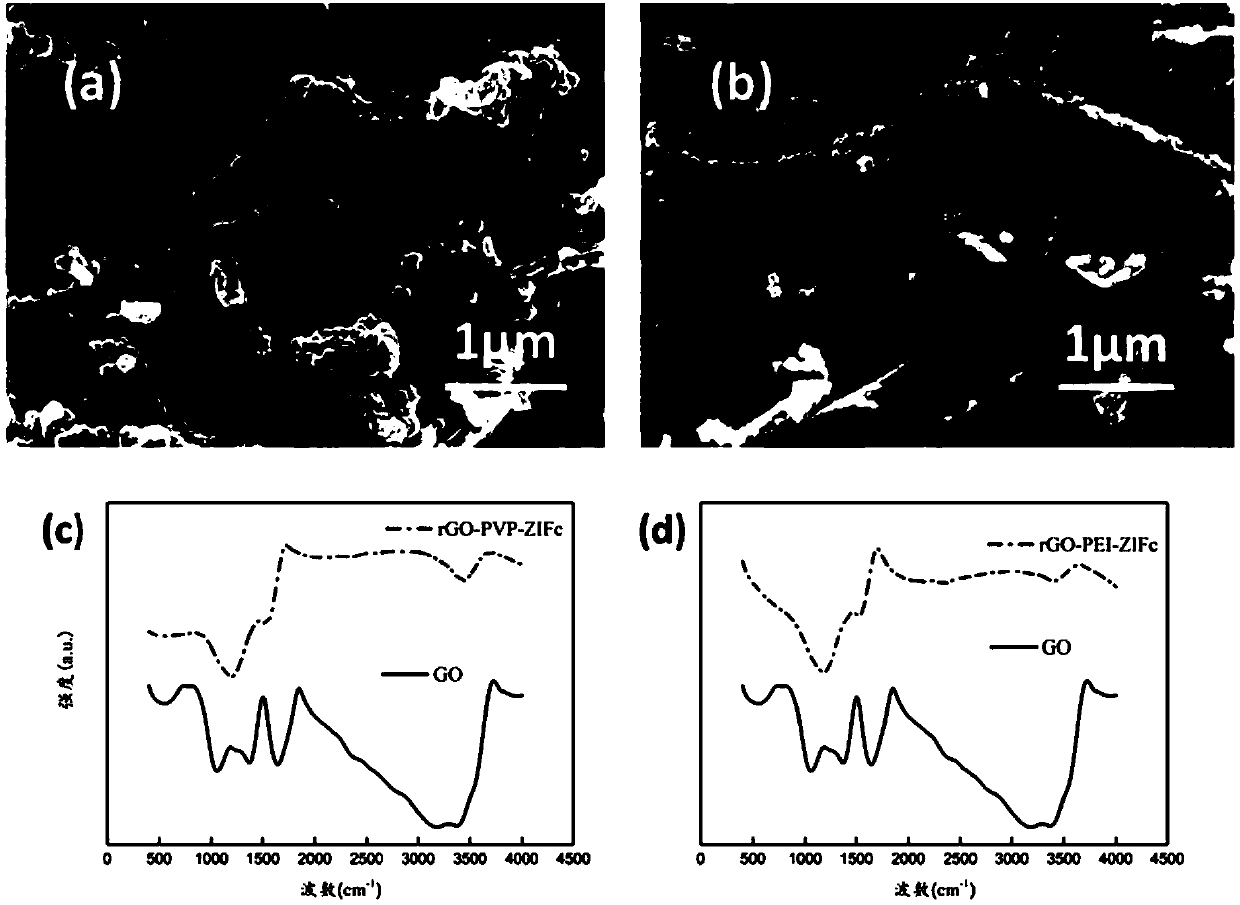

[0052] 2. Preparation of graphene-based ZIF composite catalyst: disperse the pretreated graphene oxide into deionized water (concentration about 7mg / mL); weigh 7.3g of zinc nitrate and 0.34g of ferrous sulfate, and dissolve them in 800mL of methanol And stir evenly, then add 0.5g polymethylpyrrolidone (PVP) and 10mL carbon material dispersion liquid, after stirring evenly again, add 8.5g 2-methylimidazole, keep stirring at 25°C for 24h. After the stirring was completed, the supernatant was separated by centrifugation, and the precipitate was washed three times with methanol, then transferred to a vacuum drying oven, and dried under vacuum at 70° C. overnight. After drying, high-temperature carbonization was carried out in an argon atmospher...

Embodiment 2

[0058] 1. Graphene oxide pretreatment: Wash the prepared graphene oxide with a large amount of 0.1M dilute hydrochloric acid to remove impurities contained therein, and then wash it with a large amount of water until it is nearly neutral.

[0059] 2. Preparation of graphene-based ZIF composite catalyst: disperse the pretreated graphene oxide into deionized water (concentration about 7mg / mL); weigh 7.3g of zinc nitrate and 0.34g of ferrous sulfate, and dissolve them in 800mL of methanol And stir evenly, then add 0.5g polyethyleneimine (PEI) and 10mL carbon material dispersion liquid, after stirring evenly again, add 8.5g 2-methylimidazole, keep stirring at 25°C for 24h. After the stirring was completed, the supernatant was separated by centrifugation, and the precipitate was washed three times with methanol, then transferred to a vacuum drying oven, and dried under vacuum at 70° C. overnight. After drying, high-temperature carbonization was carried out in an argon atmosphere, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com