Feedstuff for enhancing mating capability of rams and preparation method thereof

A feed and ability technology, applied in the field of animal and veterinary medicine, can solve the problems of undetermined and improved effects, and achieve the effects of strong body, improved taste of feed, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

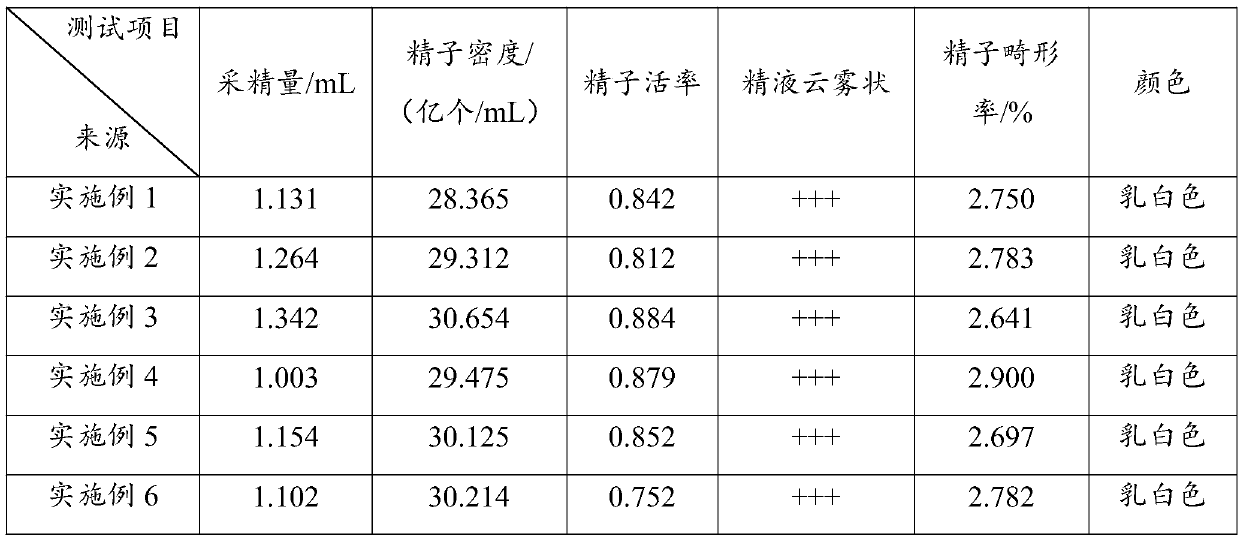

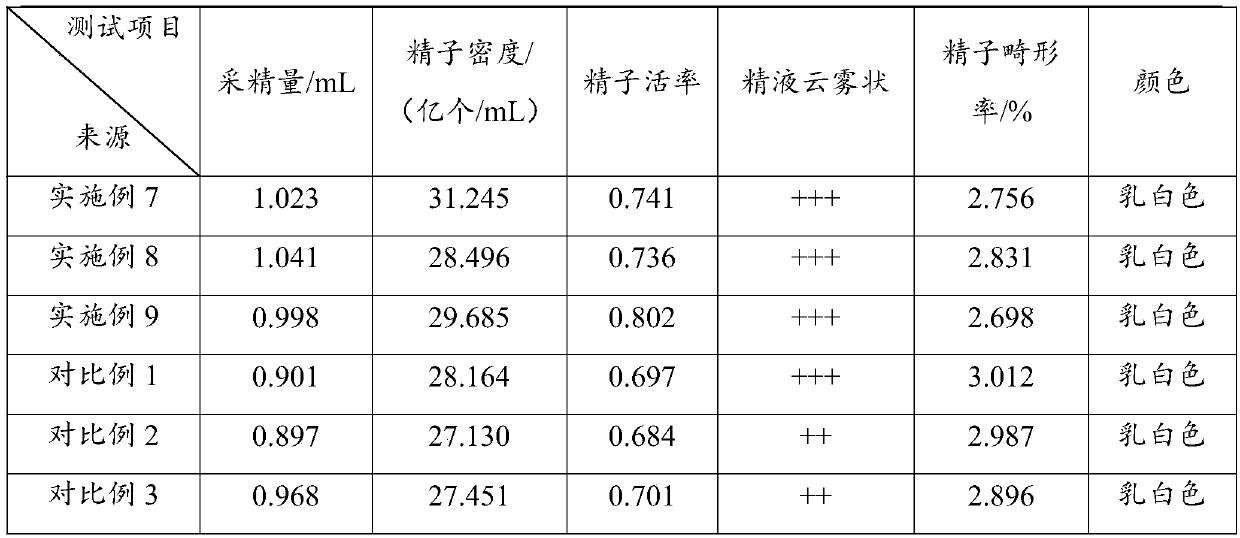

Examples

Embodiment 1

[0031] According to the weight ratio, 60% of the straw is sent to the forage grinder for crushing, and then enters the grass powder storage bin; 30% of corn, 3.0% of soybean meal, 2% of calcium hydrogen phosphate, 0.5% of salt, 2% of compound additives, and 2.5% of traditional Chinese medicine additives . Send it into a mixer (with a pulverizer), and mix all the materials in the mixer evenly; send the mixed feed to a granulator for granulation, and control the particle weight to 0.4-0.5 grams, and then send it to an induced-air dryer for drying Drying, the temperature of the dryer should be controlled at 55°C, and the drying time should be 60 minutes. After drying, the finished ram straw pellet feed can be obtained. The composite additive is composed according to the following international units or mass ratios: Vitamin A 0.8×10 5 IU, Vitamin D31.5×10 4 IU, vitamin E 100IU, zinc sulfate 1800mg, manganese sulfate 1300mg, copper sulfate 350mg, ferrous sulfate 190mg, potassium ...

Embodiment 2

[0033] According to the weight ratio, 65% of the straw is sent to the forage grinder for crushing, and then enters the grass powder storage bin; 25.5% of corn, 4% of soybean meal, 2% of calcium hydrogen phosphate, 0.5% of salt, 1% of compound additives, and 2% of traditional Chinese medicine additives . Send it into a mixer (with a pulverizer), and mix all the materials in the mixer evenly; send the mixed feed to a granulator for granulation, and control the particle weight to 0.4-0.5 grams, and then send it to an induced-air dryer for drying Drying, the temperature of the dryer should be controlled at 55°C, and the drying time should be 60 minutes. After drying, the finished ram straw pellet feed can be obtained. The composite additive is composed according to the following international units or mass ratios: Vitamin A 0.8×10 5 IU, Vitamin D31.8×10 4 IU, vitamin E 150IU, zinc sulfate 1800mg, manganese sulfate 1400mg, copper sulfate 320mg, ferrous sulfate 180mg, potassium io...

Embodiment 3

[0035] According to the weight ratio, 65% of the straw is sent to the forage grinder for crushing, and then enters the grass powder storage bin; 26% of corn, 3.5% of soybean meal, 2% of calcium hydrogen phosphate, 0.5% of salt, 1% of compound additives, and 2% of traditional Chinese medicine additives . Send it into a mixer (with a pulverizer), and mix all the materials in the mixer evenly; send the mixed feed to a granulator for granulation, and control the particle weight to 0.4-0.5 grams, and then send it to an induced-air dryer for drying Drying, the temperature of the dryer should be controlled at 55°C, and the drying time should be 60 minutes. After drying, the finished ram straw pellet feed can be obtained. The composite additive is composed according to the following international units or mass ratios: Vitamin A 0.9×10 5 IU, Vitamin D31.6×10 4 IU, vitamin E 140IU, zinc sulfate 1900mg, manganese sulfate 1500mg, copper sulfate 350mg, ferrous sulfate 200mg, potassium io...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com