Chemical indicator monitoring disinfection effect of oxidized disinfectant and monitoring method

A chemical indicator and disinfectant technology, applied in material analysis by observing the influence of chemical indicator, analysis by chemical reaction of materials, measuring device, etc., can solve problems such as unfavorable development, waiting for 24 hours, etc. Meet the needs of monitoring the disinfection effect, good indication effect, and the effect of obvious changes in color indication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

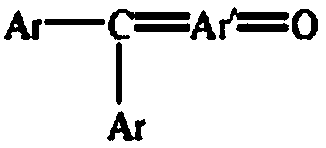

[0026] A chemical indicator for monitoring the disinfection effect of an oxidative disinfectant, comprising an indicator compound and an ink composition, the indicator compound being a triarylmethane dye, and the ink composition comprising: a solvent, a pH regulator, a viscosity modifier , defoaming agent, oil base, evaporation or drying aid, the mass percentage of the indicator compound and the ink composition is: 6-10%: 90-94%, and the structural formula of the triarylmethane dye is:

[0027]

[0028] Ar is a substituted or unsubstituted aryl group, Ar' is a substituted or unsubstituted cyclohexadienyl group, wherein Ar is a phenyl or a substituted phenyl group, and the substituents on Ar include hydroxyl, halogen (such as bromine or chlorine), the following Alkyl (such as methyl, ethyl or isopropyl), sulfonate and carboxyl, the color of the triarylmethane dyes can change significantly when exposed to oxidizing disinfectants.

[0029] As a preferred manner, the substituen...

Embodiment 2

[0056] A kind of chemical indicator that monitors the disinfection effect of oxidizing disinfectant, comprises indicator compound and ink composition, and described indicator compound is rosebic acid, and described ink composition comprises: solvent, pH value adjusting agent, viscosity modifier, Defoaming agent, oil base, evaporation or drying aid, the mass percentage of the chemical indicator is: rose red acid 6%, hydroxyethyl cellulose 2.65%, sodium hydroxide 1%, acrylic resin 0.5%, ammonia 0.25% , 0.1% of non-foaming non-ionic mineral oil, 89.5% of water, and the color of the rhodinic acid dye can change obviously when it is exposed to an oxidative disinfectant in the disinfection process.

[0057] As a preferred manner, the indicator compound not only changes color during the ozone disinfection process, but also presents double visual changes during the two and a half cycle disinfection processes. The initial state of the compound is red, which turns orange or light orange...

Embodiment 3

[0066] A chemical indicator for monitoring the disinfection effect of an oxidative disinfectant, comprising an indicator compound and an ink composition, the indicator compound being rosebic acid, and the ink composition comprising: a solvent, a pH regulator, a viscosity modifier, Defoaming agent, oil base, evaporation or drying aid, the mass percentage of the chemical indicator is: rose red acid 10%, hydroxyethyl cellulose 3.45%, sodium hydroxide 2.6%, acrylic resin 2.5%, ammonia 0.85% , 0.3% of non-foaming non-ionic mineral oil, 80.3% of water, and the color of the rhodinic acid dye can change obviously when exposed to an oxidative disinfectant in the disinfection process.

[0067] As a preferred manner, the indicator compound not only changes color during the ozone disinfection process, but also presents double visual changes during the two and a half cycle disinfection processes. The initial state of the compound is red, which turns orange or light orange after the first h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com