Palmitic acid modified tapioca starch preparation method

A tapioca starch and palmitic acid technology, applied in the field of starch modification, can solve the problems of low reaction efficiency of palmitic acid modified starch, and achieve the effects of improving esterification degree and reaction efficiency, simple operation and reducing side reactions of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

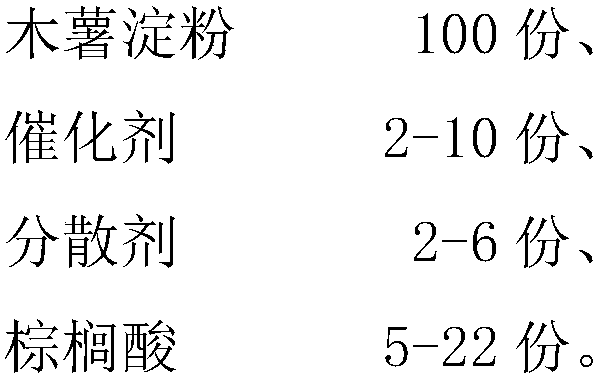

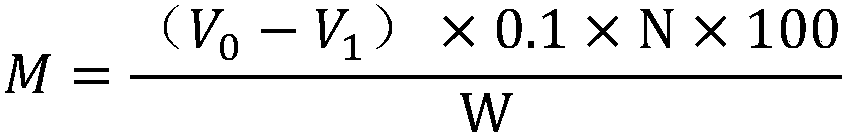

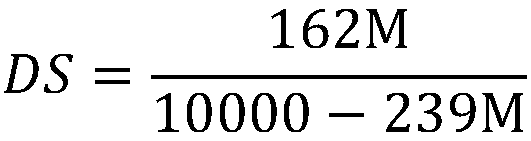

Method used

Image

Examples

Embodiment 1

[0018] 1. Take 100 parts of dry tapioca starch and add it to the kneader, then dissolve 4 parts of sodium bicarbonate in an appropriate amount of distilled water, control the water content of the system to 20%, add it to the starch, mix well, activate the starch hydroxyl group, add 3 Parts of Sodium Chloride.

[0019] 2. Then add 20 parts of palmitic acid, mix thoroughly for 5-10 minutes, keep the temperature at 135°C, and react for 2 hours to obtain a white solid crude product.

[0020] 3. After the reaction, take it out and cool it to room temperature, and grind it through a 100-mesh sieve.

[0021] 4. Wash 2-3 times with 70% ethanol solution, then dry the product in an oven at 45°C, crush it, add 1 part of silicon dioxide, and set aside.

Embodiment 2

[0023] 1. Take 100 parts of dry tapioca starch and add it to the kneader, then dissolve 4 parts of sodium carbonate in an appropriate amount of distilled water, control the water content of the system to 20%, add it to the starch, mix thoroughly to activate the starch hydroxyl group, and add 3 parts potassium chloride.

[0024] 2. Then add 9 parts of palmitic acid, mix thoroughly for 5-10 minutes, keep the temperature at 130°C, and react for 3 hours to obtain a white solid crude product.

[0025] 3. After the reaction, take it out and cool it to room temperature, and grind it through a 100-mesh sieve.

[0026] 4. Wash 2-3 times with 70% ethanol solution, then dry the product in an oven at 45°C, crush it, add 1 part of bentonite, and set aside.

Embodiment 3

[0028] 1. Take 100 parts of dry tapioca starch and add it to the kneader, then dissolve 4 parts of disodium hydrogen phosphate in an appropriate amount of distilled water, control the water content of the system to 20%, add it to the starch, and mix thoroughly to activate the starch hydroxyl group, add 2 parts sodium chloride.

[0029] 2. Then add 13 parts of palmitic acid, mix thoroughly for 5-10 minutes, keep the temperature at 125°C, and react for 3 hours to obtain a white solid crude product.

[0030] 3. After the reaction, take it out and cool it to room temperature, and grind it through a 100-mesh sieve.

[0031] 4. Wash 2-3 times with 70% ethanol solution, then dry the product in an oven at 45°C, crush it, add 1 part of silicon dioxide, and set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com