Core-shell structure silt solidification unsintered ceramisite and preparation method thereof

A technology for solidifying silt and shell structures, applied in the field of building materials, can solve the problems of water absorption, environmental pollution of silt ceramsite, energy consumption, etc., achieve good interface bonding, solve the problem of water absorption, and ensure the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

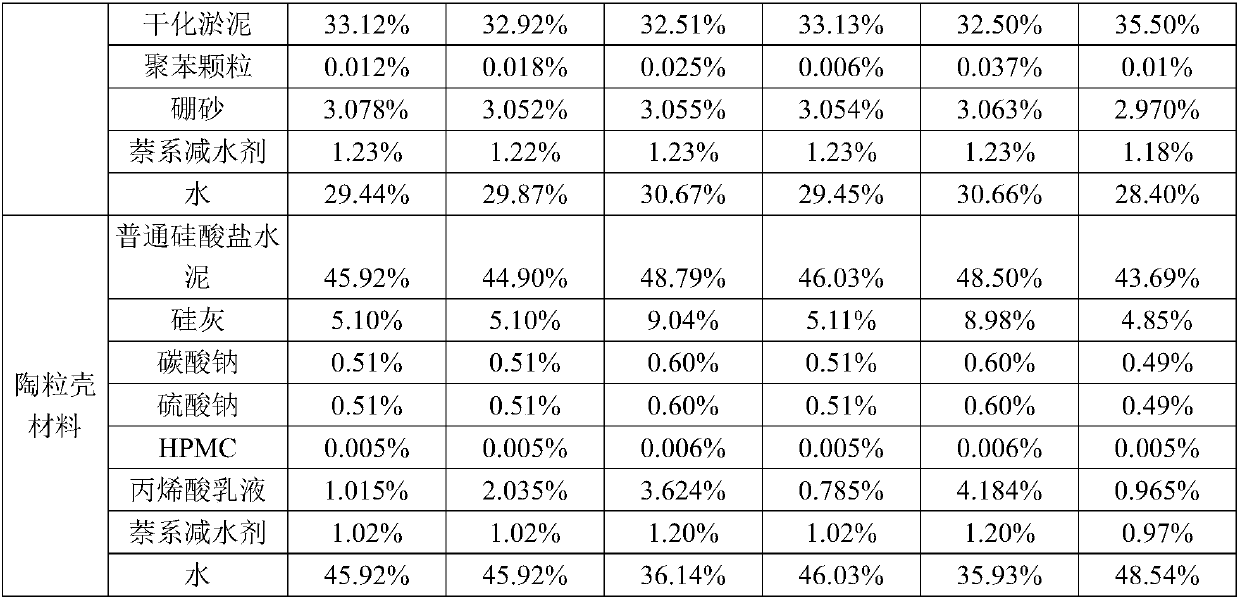

Examples

Embodiment -1

[0034] Potassium dihydrogen phosphate is produced by Sichuan Zhongxin Shulong Chemical Co., Ltd., industrial grade; percalcined magnesium oxide is produced by Shijiazhuang Jinyu Magnesium Industry Co., Ltd., and the calcination temperature is 1350°C. Fly ash is produced by Nanjing Gongchuang Anti-corrosion and Insulation Co., Ltd., Class I fly ash; silica fume is produced by Shanghai Shengkuo Building Materials Co., Ltd., SiO 2 The content is more than 95%, and the activity index is greater than 105%. The dried sludge is obtained from Taihu Lake bottom mud after natural drying and grinding, with an average particle size of less than 0.075mm; polyphenylene particles are produced by Hebei Langfang Huifeng Thermal Insulation Material Co., Ltd., with a particle size of 3mm ; Borax, sodium carbonate, and sodium sulfate are produced by Tianjin Kemiou Chemical Reagent Co., Ltd., industrial grade; naphthalene-based water reducer is produced by Jiangsu Subote New Materials Co., Ltd., wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com