Vacuum glass vertical type vacuum pumping loading vehicle, vacuum pumping device, preparation method and vacuum glass

A vacuum glass and vacuuming technology, which is applied to trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of temperature control in unfavorable cover plate areas, redundant individual action control, etc., to improve positioning effects, increase processing capacity, and improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

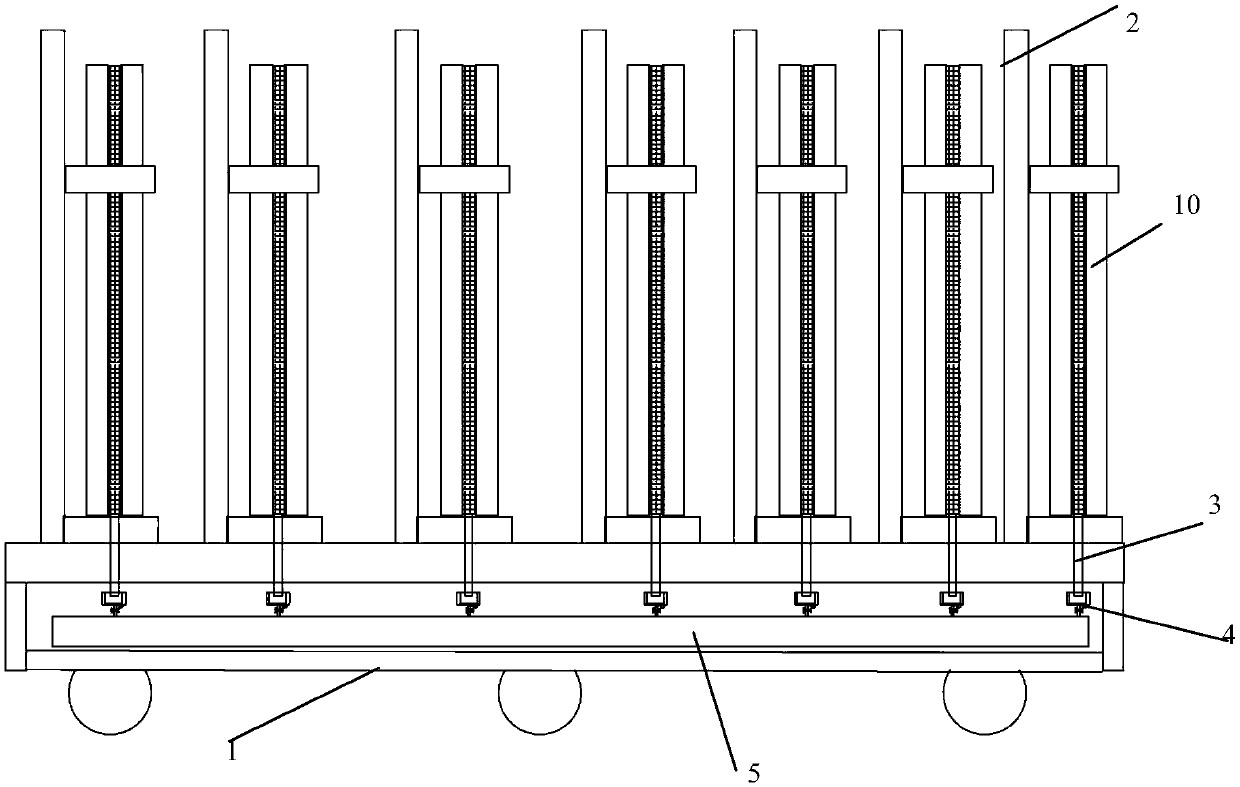

[0029] A vertical vacuum-pumping vehicle for vacuum glass, including a heat-insulating platform 1 with rollers at the bottom, and a supporting mechanism set on the platform to support and position multiple groups of vacuum glass groups 10 and arrange them vertically at intervals 2. One by one, the sealing joint 4 used to connect with the vacuum glass tube 3 of the vacuum glass group correspondingly, the vacuum mother tube 5 arranged under the carrier and correspondingly connected to the sealing joint , and a vacuum pump system (not shown) communicated with the vacuum main pipe.

[0030] The vacuumized vehicle of the present invention is suitable for the one-step operation of heating edge sealing and vacuuming of the vertical vacuum glass group. The vacuumized glass tube is a glass tube, and its upper end goes deep into the vacuum glass group, which can be set in The corner, middle or arbitrary setting position of the vacuum glass group, for example, realizes its positioning by...

Embodiment 2

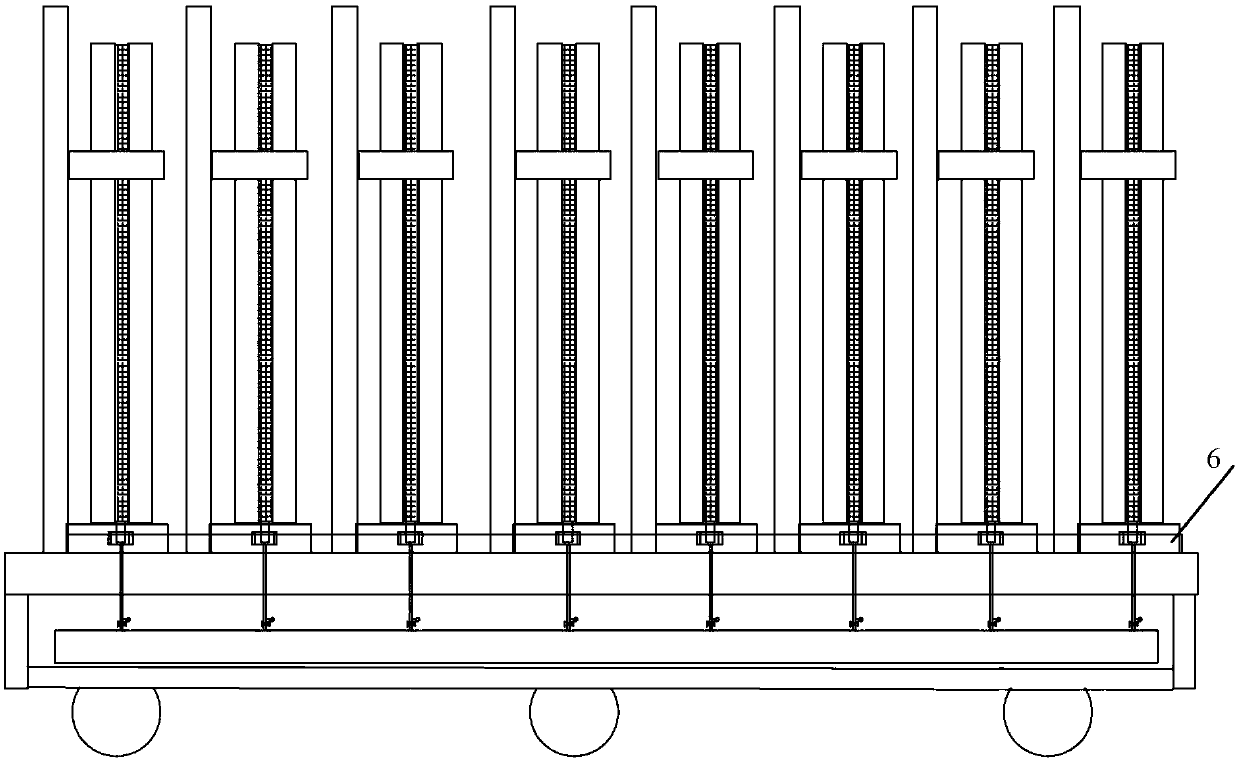

[0036] In order to realize the sealing connection, the sealing joint is arranged on the platform, and the sealing structure includes a docking pipe with a docking port formed on the upper end, and is arranged on the docking pipe to receive the docking port. Tight clamp. Preferably, a water-cooling tube is also provided on the carrier, and the butt joint passes through the water-cooling tube 6 and then passes through the carrier to connect with the vacuumized glass tube.

[0037] Set the sealing joint on the stage, and after positioning the vacuum glass group to be edge-sealed, the vacuumed glass tube can be inserted into the butt joint and manually or automatically locked by the clamp to realize the sealed connection. Circulating water-cooled pipes use water-cooled pipes to cool the butt joints, effectively avoiding the downward transfer of heat, and ensuring that the sealing effect of the joints is not affected by high temperature, improving the sealing connection effect.

...

Embodiment 3

[0041] A vacuum glass processing device, characterized in that it includes an inverted U-shaped furnace body, a plurality of the above-mentioned vacuum glass vertical vacuum-pumping vehicles, and the vacuum-pumping vehicles enter the U-shaped furnace body sequentially and are carried The platform constitutes the bottom surface of the furnace body.

[0042]Among them, a plurality of high-temperature-resistant circulating fans are arranged on the left and right side walls of the furnace body to blow the hot air in the furnace into between two adjacent vacuum glass groups. High temperature resistant circulation fan.

[0043] The vacuum glass processing device of the present invention utilizes a vacuumized vehicle to form the bottom of the lower open furnace body, realizes continuous production in a circular on-line manner, realizes continuous edge sealing and vacuuming, and reduces energy consumption caused by multiple heating , improve production efficiency, and use high-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com