Method of producing high-purity quartz sand without producing quartz tailings

A production method, the technology of quartz tailings, applied in the direction of silica, solid separation, silica, etc., to achieve the effect of high raw material utilization rate, high product purity, and less facility investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

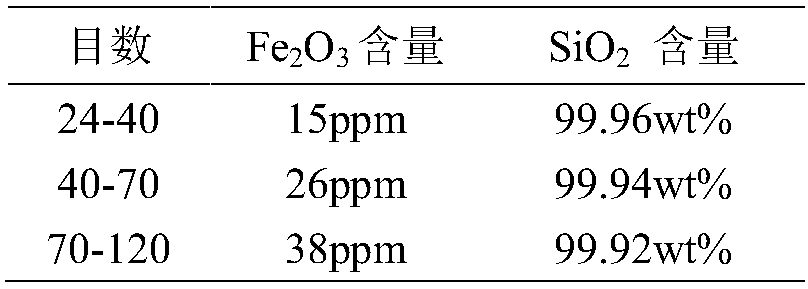

Embodiment 1

[0036] The process of the present invention is described as raw material with the quartzite ore produced in a certain place in Guangdong:

[0037] 1. Pretreatment of ore: Wash the yellow ore purchased from the mine with tap water first, and then crush it with a 400×600 jaw crusher until the particle size is 10-50mm for use; the material below 10mm is separated for another For other purposes, it can be used as raw material for foundry sand; the waste water after washing the ore is purified and then recycled;

[0038] 2. chemical treatment: the material in the step 1 is sent into the pickling purification device of the publication number CN103382087B with 5wt% concentration oxalic acid at 95 DEG C to carry out the acid liquid circulation heating chemical impurity removal treatment after 4 hours, let off the acid liquid, After washing the ore particles with tap water until neutral, all the yellow on the surface of the quartz particles will be eliminated and become as white as sno...

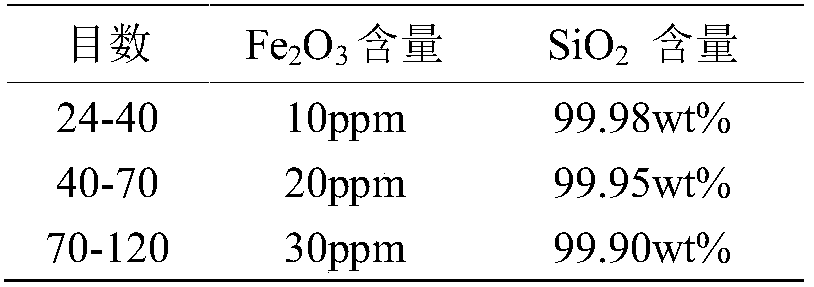

Embodiment 2

[0052] The process of the present invention is described as raw material with the produced vein quartzite ore of a certain in Hubei:

[0053] 1. Pretreatment of ore: Wash the ore polluted by yellow mud purchased from the mine with tap water first, then use a 400×600 jaw crusher to crush it into particles with a particle size of 10-50mm for use; the waste water after washing the ore Recycle after purification;

[0054]2. chemical treatment: the material in the step 1 is sent into the pickling purification device of the publication number CN103382087B with 20wt% concentration hydrochloric acid at 90 DEG C to carry out the acid liquid circulation heating chemical impurity removal treatment after 4 hours, let off the acid liquid, After washing the ore particles with tap water to neutral, all the yellow on the surface of the quartz particles will be eliminated and become translucent, and then the washed quartz particles will be sent to drying for later use; the washing water for wa...

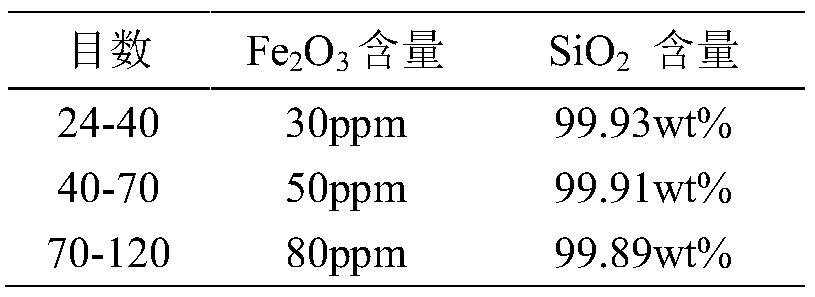

Embodiment 3

[0068] The process of the present invention is described as raw material with the quartzite ore produced in a certain place in Anhui:

[0069] 1. Pretreatment of ore: Wash the yellow ore purchased from the mine with tap water first, and then crush it with a 400×600 jaw crusher to a particle size of 10-50mm for use; the wastewater after washing the ore is purified recycle;

[0070] 2. Chemical treatment: send the material in step 1 into the pickling purification device with publication number CN103382087B and use 2%wt HF at 80°C to carry out the acid liquid circulation heating and chemical impurity removal treatment for 4 hours, then let off the acid liquid, After the ore particles are washed with tap water to neutral, the yellow color on the surface of the quartz particles is completely eliminated, and then the washed quartz particles are sent to drying for standby; the washing water for washing the quartz particles is sent to the water treatment station to neutralize and prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com