Straw dehydration extrusion forming machine

A technology of forming machine and straw, which is applied in the direction of material forming press, press, solid fuel, etc., can solve the problems of low straw density, high transportation cost, waste of resources, etc., achieve low moisture content, reduce transportation process, reduce The effect of shipping costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

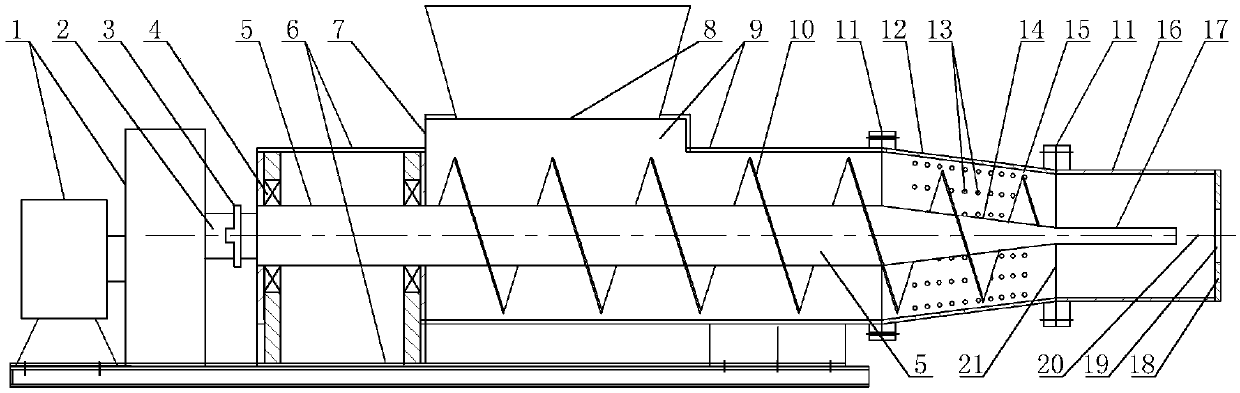

[0029] The straw dehydration extrusion molding machine has a frame 6 on which an auger and a pressing pipe are installed. The pressing pipe is composed of a feeding pipe 9 and a tapered pipe 12. The feeding port 8 is provided on the feeding pipe, and the feeding pipe One end is a blind end 7, and the other port is connected to the wide-mouth flange of the tapered pipe. The narrow mouth end of the tapered pipe is a discharge port 21, and a plurality of gas-liquid discharge holes 13 are provided on the pipe wall of the tapered pipe; The auger has a main shaft 5, one end of the main shaft is rotatably connected to the frame, the other end of the main shaft is placed in the pressure material pipe, and the shaft body is fixedly connected with a spiral rib 10, and the axis line 20 of the main shaft is connected with the axis line of the tapered tube. coincide. The outer circle of the spiral ribs placed in the tapered tube is conically inclined along the direction of the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com