Blade processing machine tool integrating processing and detecting functions

A technology for processing machine tools and blades, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of difficult to balance processing efficiency, processing quality, processing flexibility, etc., to achieve the convenience of structural layout and motion control, force Reasonable, the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

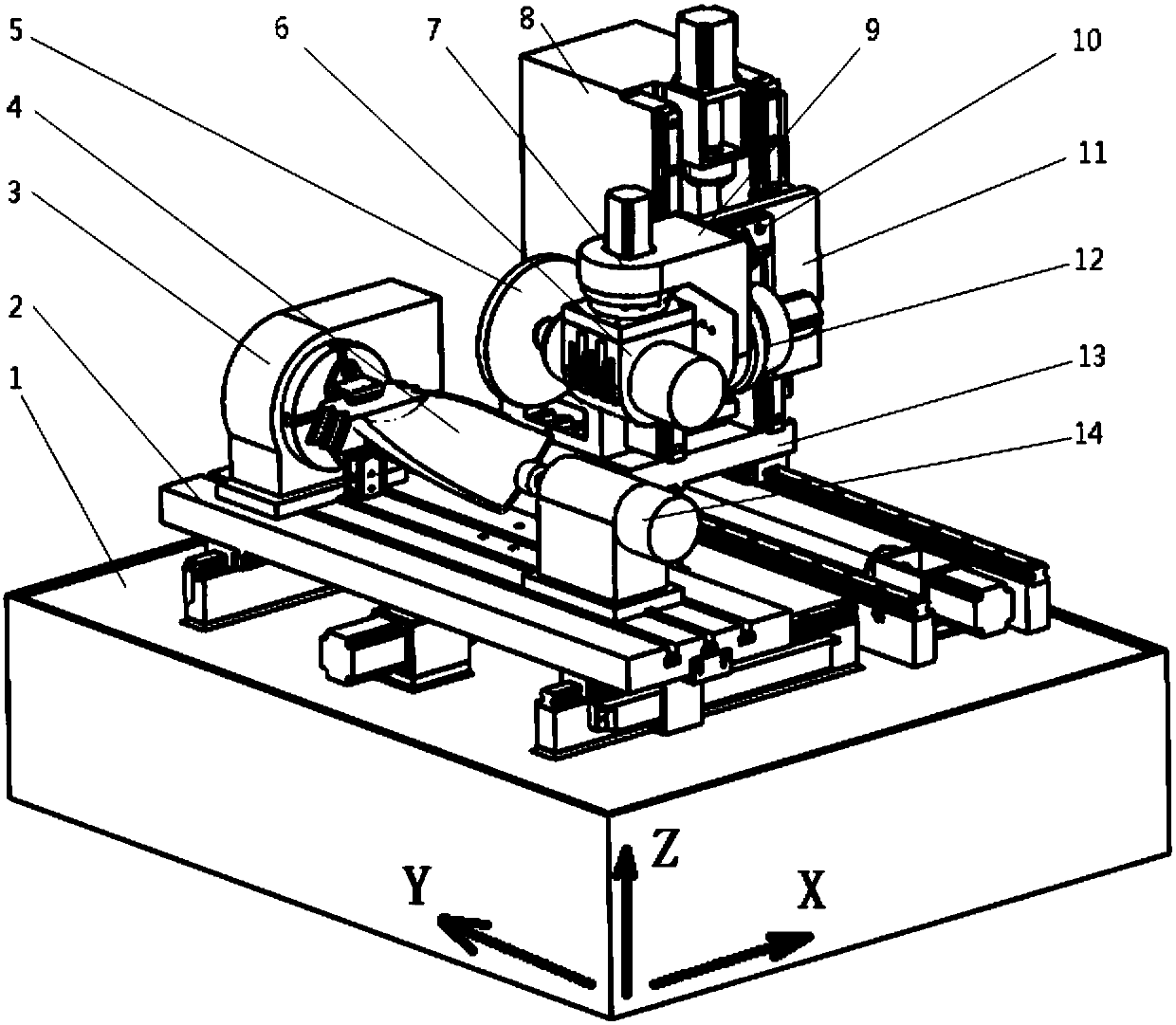

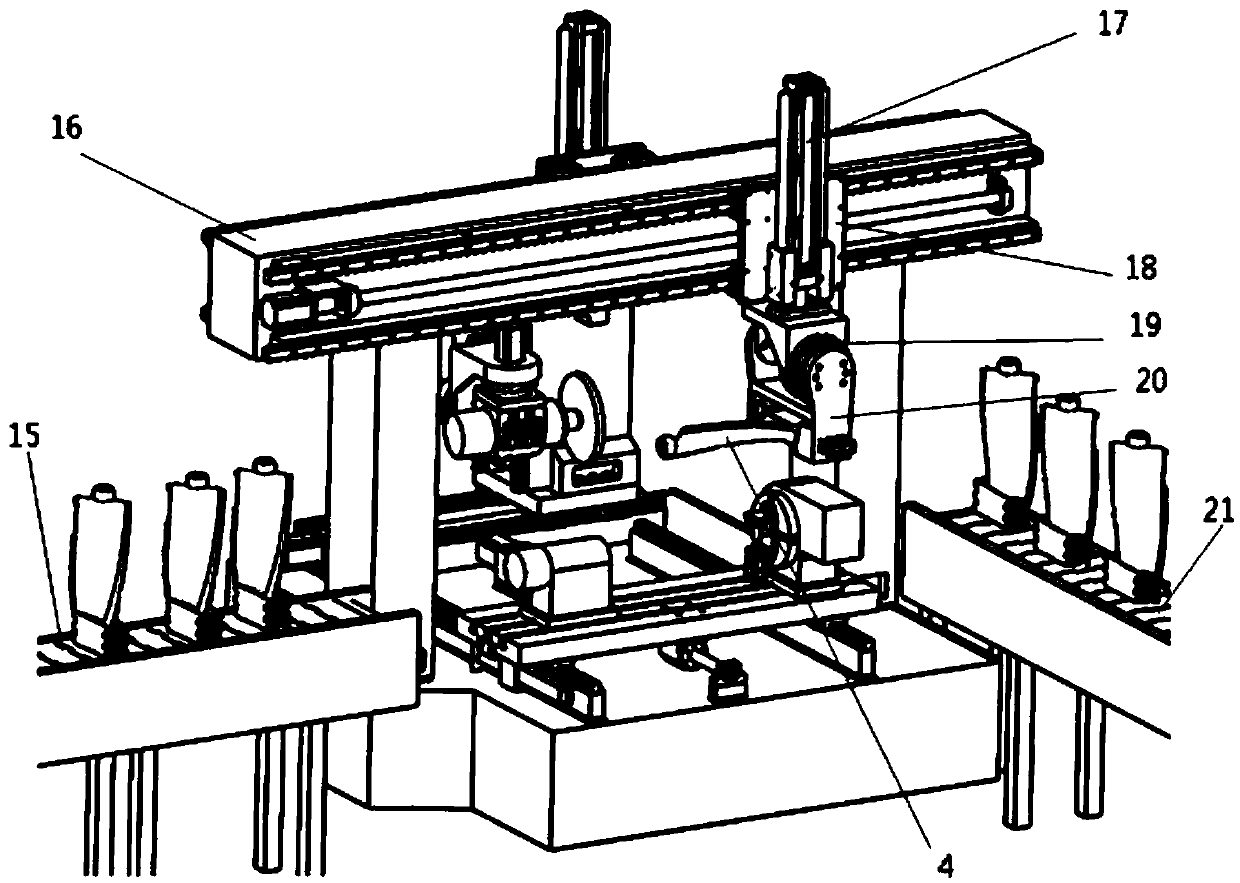

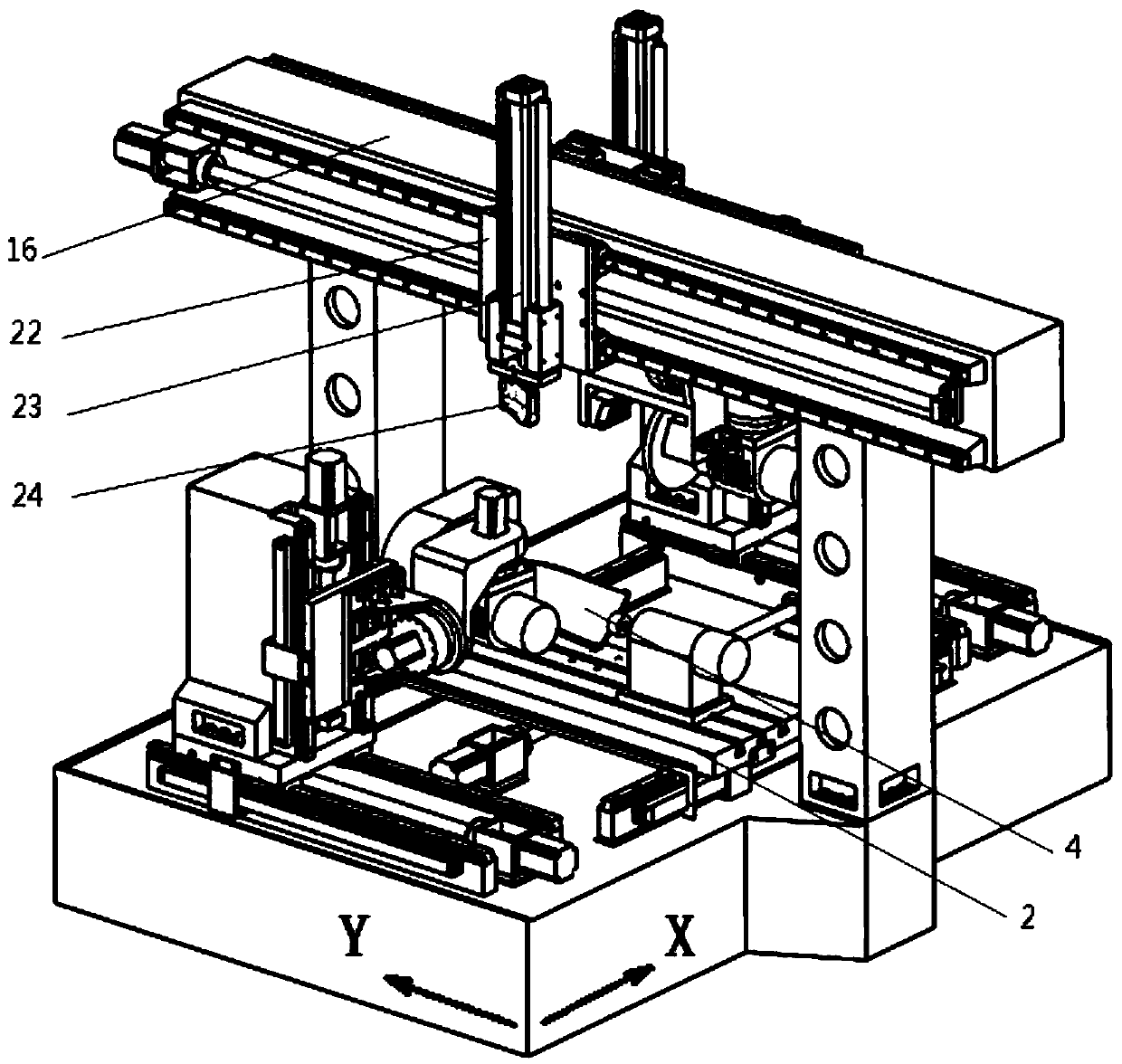

[0021] The device of the present invention includes a machine tool processing unit, an automatic feeding and discharging unit and an automatic detection unit, referring to figure 1 , the structure of the machine tool processing unit is to include a base 1, a longitudinal slide rail and a transverse slide rail are arranged on the base 1, and a workbench 2 (referred to as the workpiece side) is arranged on the transverse slide rail (along the X direction) of the base 1, The workbench 2 is provided with a horizontal turntable 3 and a tailstock 14 opposite to each other in the longitudinal direction (along the Y direction), and the horizontal turntable 3 installs the workpiece 4 alone, or clamps and supports the workpiece 4 together with the tailstock 14;

[0022] On the longitudinal slide rail (along the Y direction) of the base 1, a sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com