Precise machine punching device

A punching device and precision machinery technology, applied in the direction of positioning devices, clamping devices, metal processing machinery parts, etc., can solve the problems of arm pain, affecting the accuracy of drilling, and the punching machine cannot be used without fixing devices, etc. Achieve weight loss and avoid arm soreness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

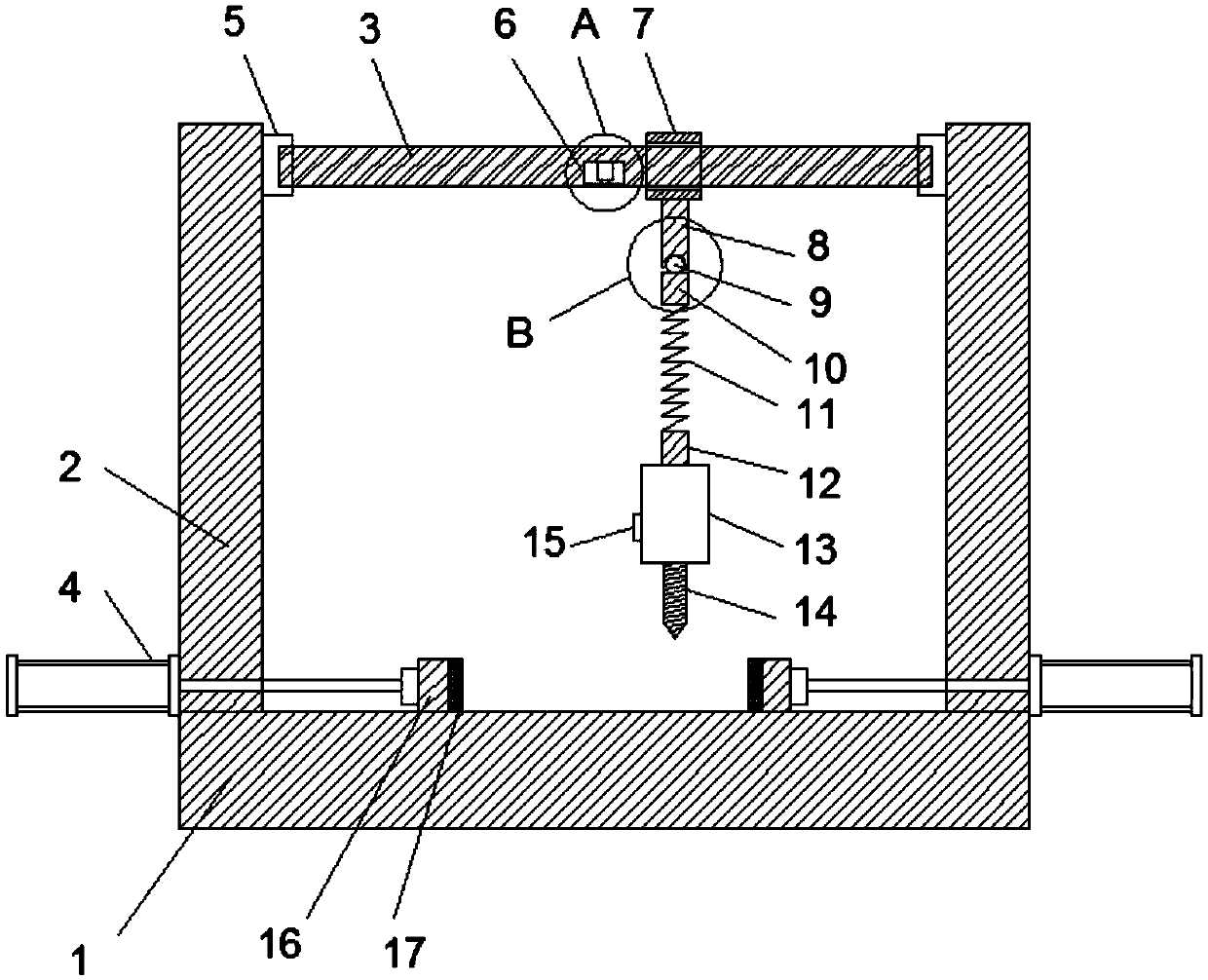

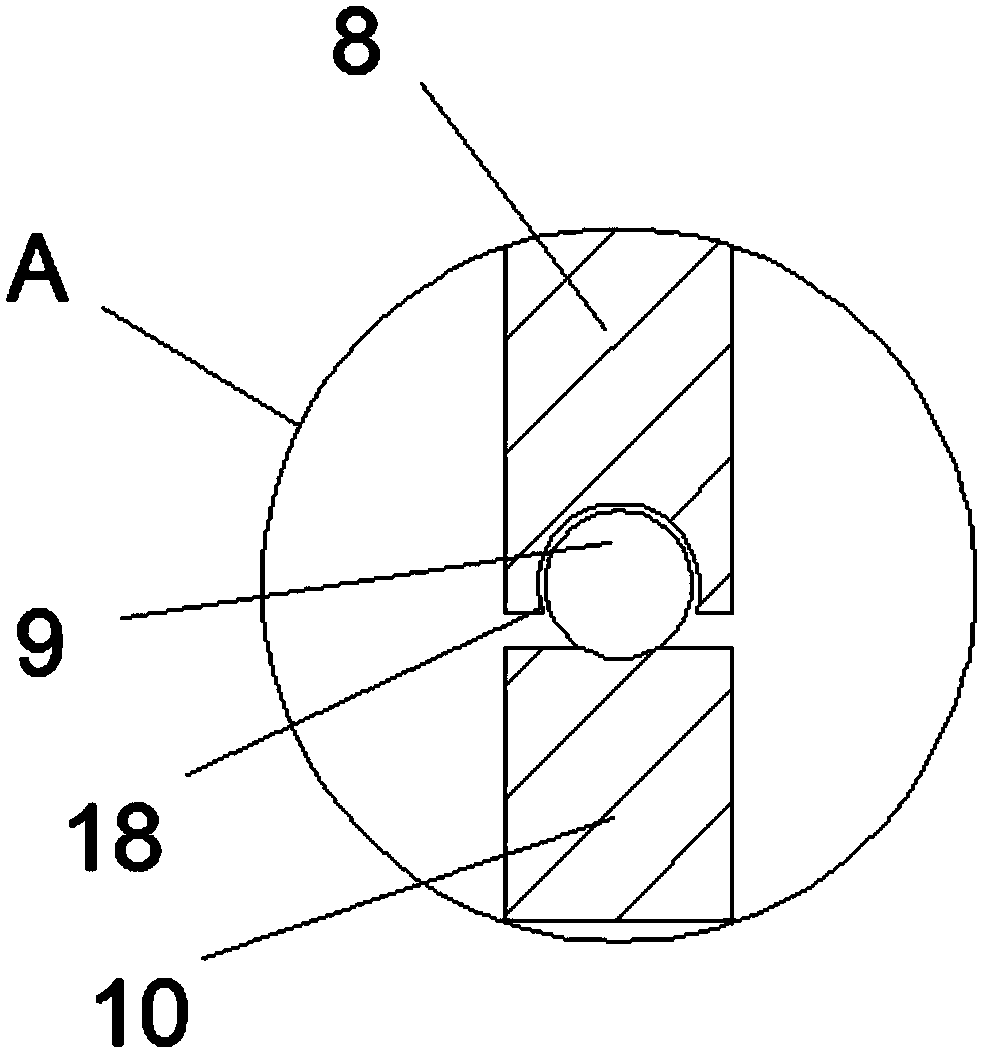

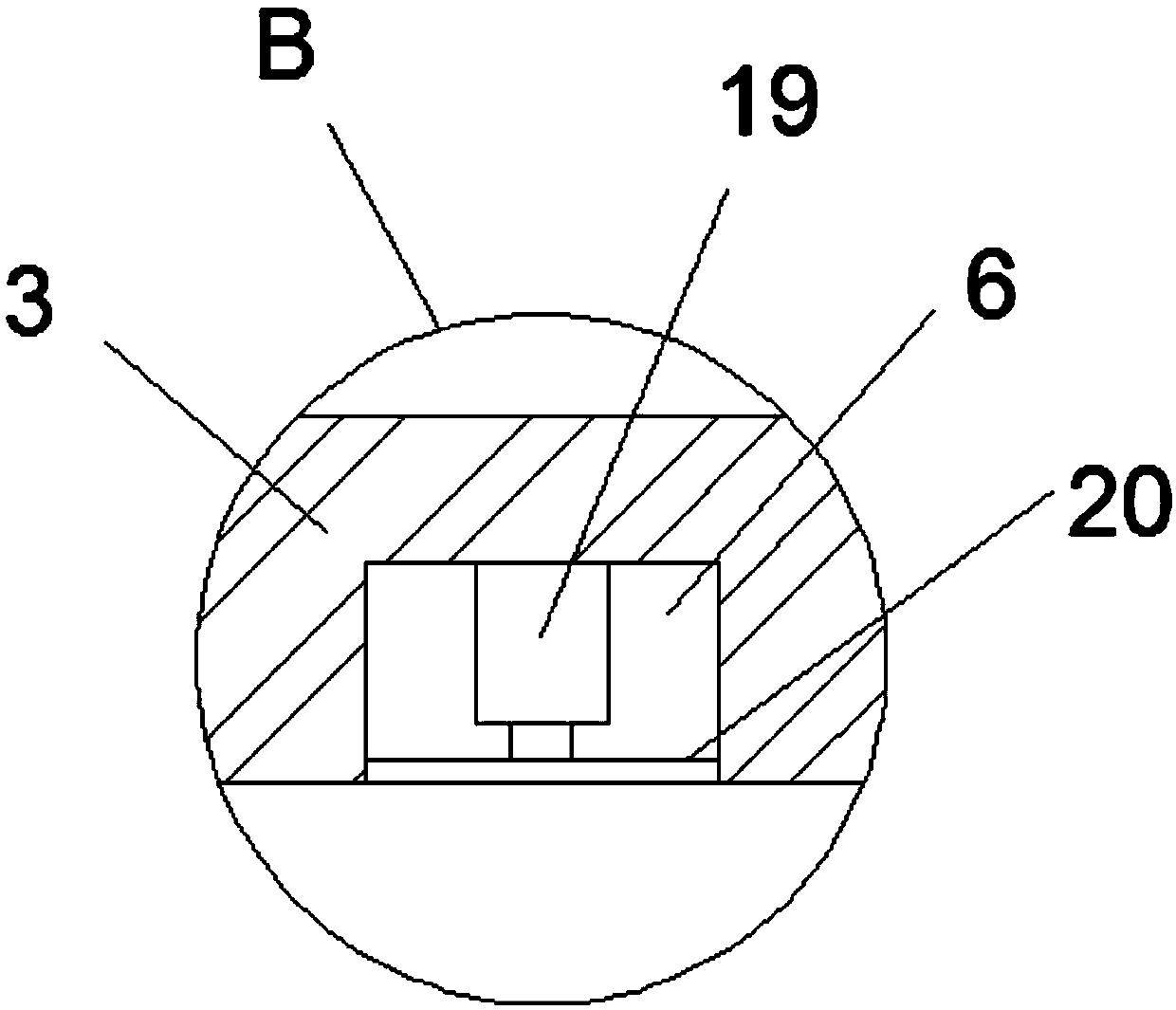

[0018] Please refer to Figure 1-3 As shown, a precision mechanical punching device includes a base 1, a support rod 2 and a cross bar 3, the support rod 2 is fixed on both sides of the upper surface of the base 1, and the inner side of the upper end of the support rod 2 passes through a fixed block 5 A crossbar 3 is connected, and a collar 7 is slidably connected to the crossbar 3. A connecting rod 8 is fixed on the bottom surface of the collar 7. A spherical groove 18 is provided on the bottom surface of the connecting rod 8. In the spherical groove 18, A rolling ball 9 is provided, the bottom surface of the rolling ball 9 is fixed with a first connecting column 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com