Mounting equipment for multi-size chips

A multi-size, chip technology, applied in electrical components, electrical components, circuits, etc., can solve problems such as low work efficiency, inability to adapt to complex situations, and inability to mount chips of different sizes at the same time, so as to improve work efficiency and apply Wide range and effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

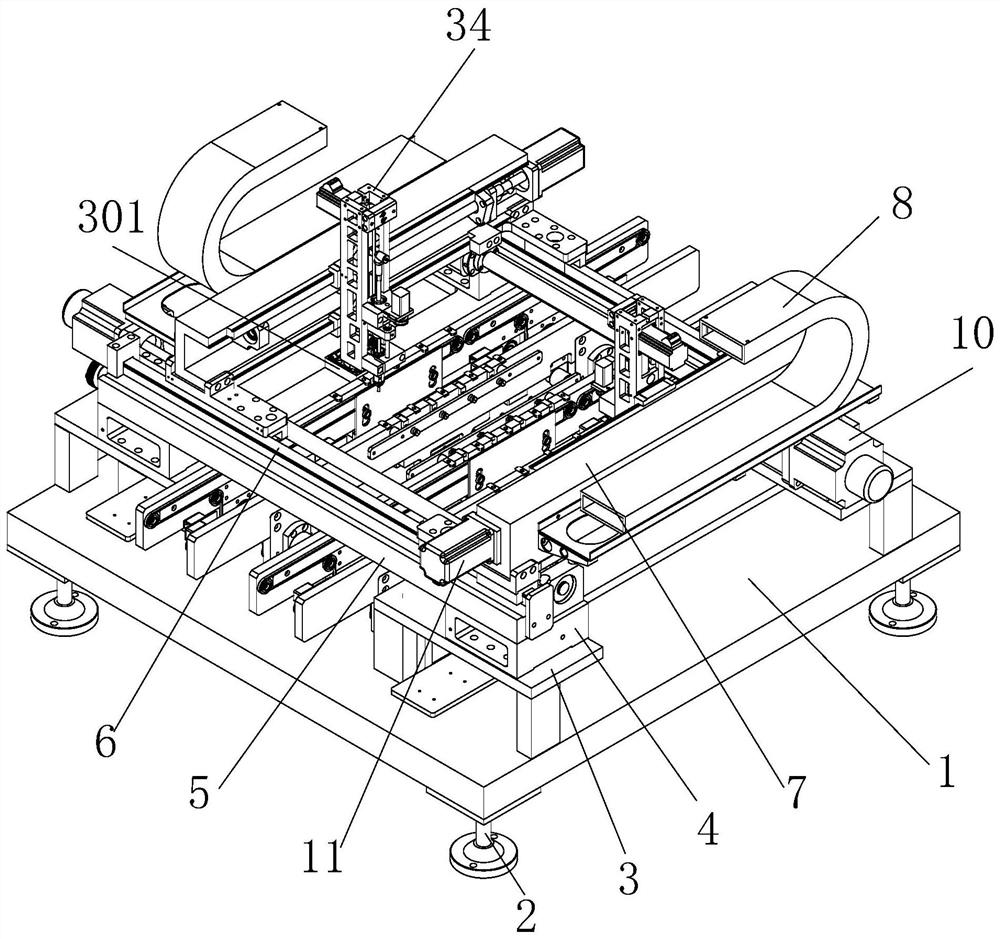

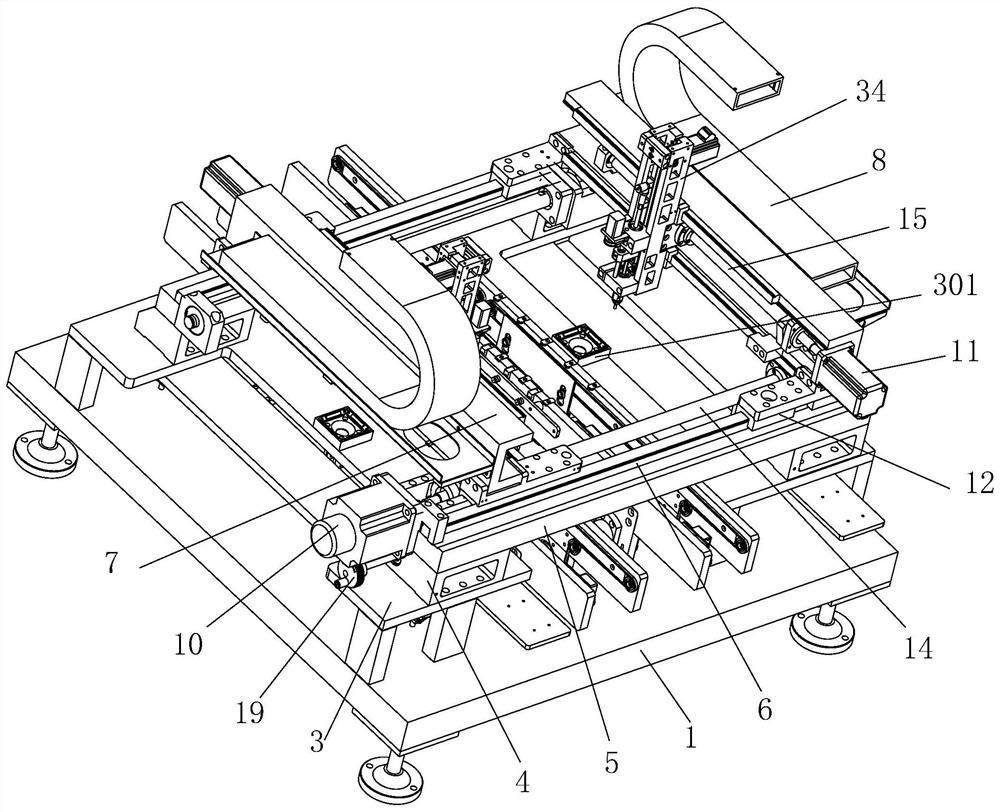

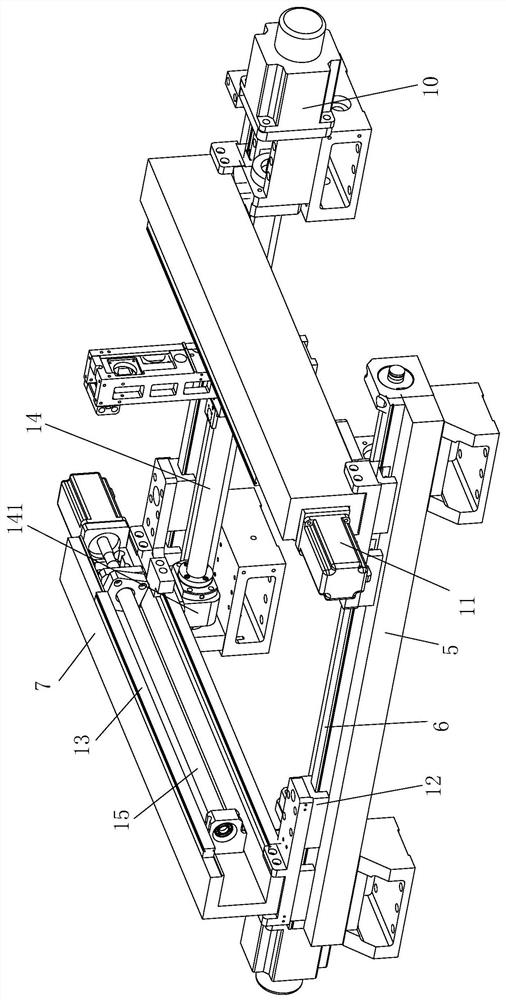

[0035] Embodiment 1: A mounting device for multi-size chips, comprising a support base 1, a support cross bar 5, a U-shaped fixed rod 7 and a mounting suction nozzle 39, the support base 1 is provided with two fixing seats 3, Two supporting bars 5 perpendicular to the direction of the fixing seat 3 are installed on the fixing seat 3, a first screw 14 is arranged on one side of the supporting bar 5, and one end of the first screw 14 is connected with The first motor 10, the first screw mandrel 14 is sleeved with a first screw mandrel cover 141 that can move relative to the first screw mandrel 14, and each first screw mandrel cover 141 is connected with a first slider 12. The first slider 12 is slidably connected to the first slide rail 6 above the support cross bar 5, and each first slide rail 6 is provided with a first slider 12;

[0036] A U-shaped fixed rod 7 is slidably connected above the first slide rail 6, and the U-shaped fixed rod 7 is connected to the first slider 12 ...

Embodiment 2

[0043] Embodiment 2: A mounting device for multi-size chips, comprising a support base 1, a support cross bar 5, a U-shaped fixing bar 7 and a mounting suction nozzle 39, the support base 1 is provided with two fixing seats 3, Two supporting bars 5 perpendicular to the direction of the fixing seat 3 are installed on the fixing seat 3, a first screw 14 is arranged on one side of the supporting bar 5, and one end of the first screw 14 is connected with The first motor 10, the first screw mandrel 14 is sleeved with two first screw mandrel sleeves 141 that can move relative to the first screw mandrel 14, and each first screw mandrel sleeve 141 is connected with a first slide Block 12, the first slide block 12 is slidably connected on the first slide rail 6 above the support cross bar 5, and each first slide rail 6 is provided with two first slide blocks 12;

[0044] Two U-shaped fixed rods 7 are slidably connected above the first slide rail 6, and the U-shaped fixed rods 7 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com