Conveniently adjusted grinding device for bearing processing

A bearing processing and grinding technology, applied in the field of bearing processing, can solve problems such as grinding of parts that affect clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

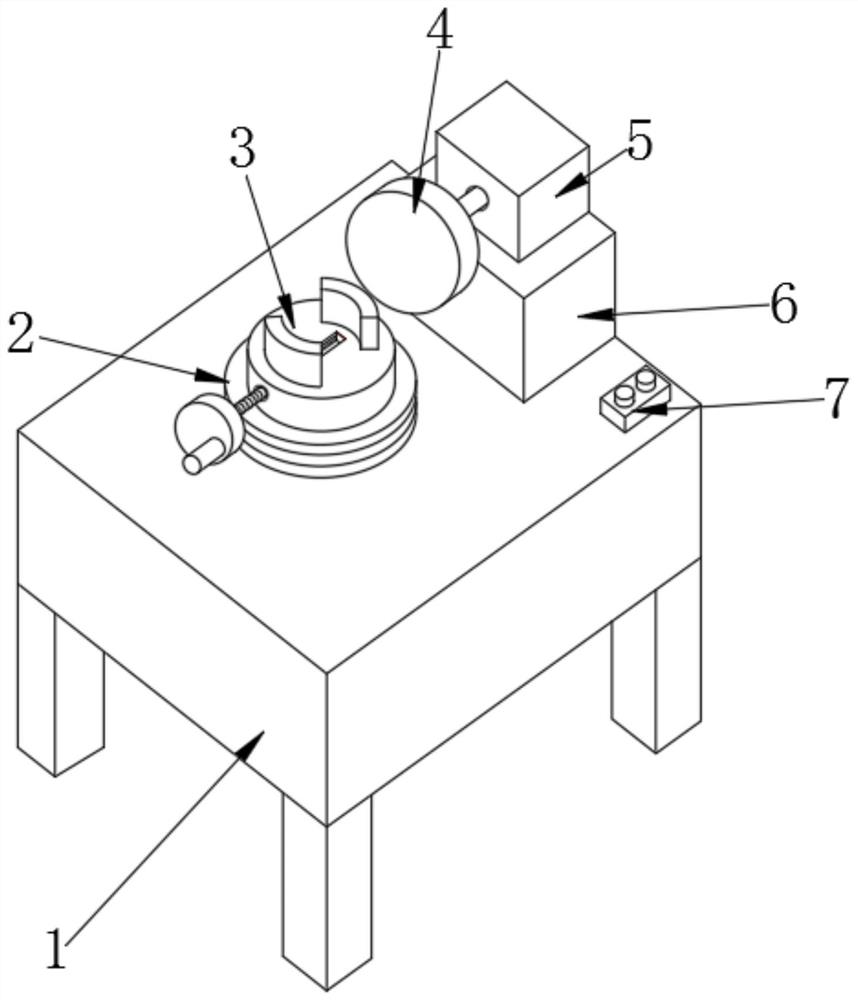

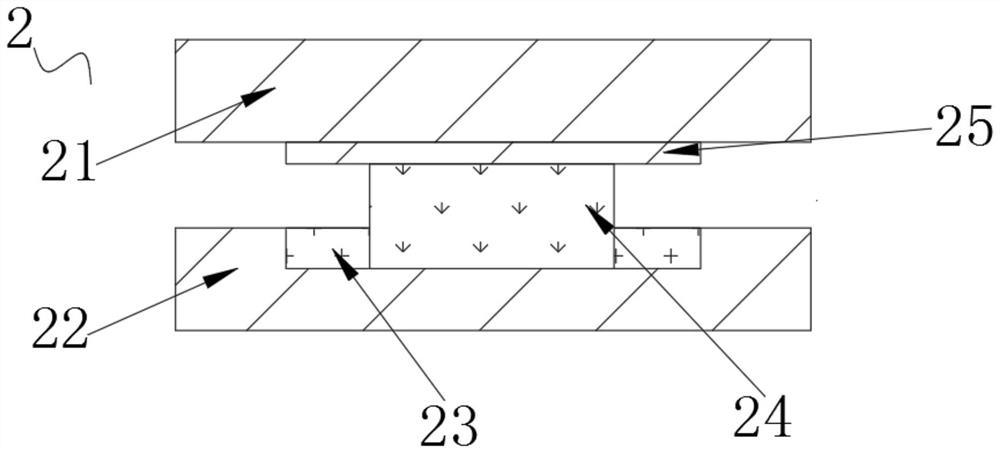

[0022] see Figure 1~6 , in an embodiment of the present invention, a conveniently adjustable grinding device for bearing processing includes a workbench 1, a controller 7 is connected to the upper side of the workbench 1, and a rotating mechanism 2 is connected to the upper middle part of the workbench 1 to rotate The inside of the mechanism 2 includes a second turntable 22 connected to the top of the workbench 1. A ball bearing 23 is embedded above the second turntable 22. A connecting block 24 is connected above the ball bearing 23. A pad is connected above the connecting block 24. The sheet 25 and the top of the spacer 25 are connected with a first turntable 21 .

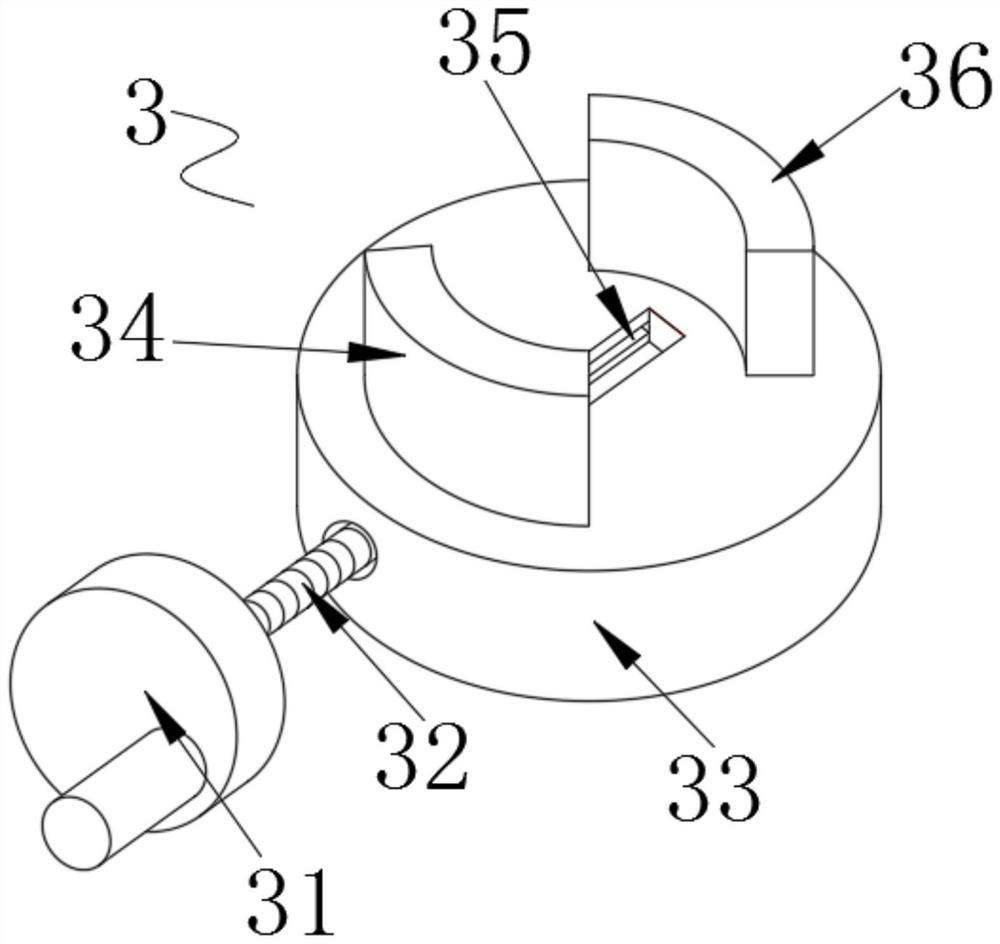

[0023] exist image 3 Middle: the top of the rotating mechanism 2 is connected with the fixing mechanism 3, the interior of the fixing mechanism 3 includes the first base 33 connected with the upper part of the rotating mechanism 2, the upper part of the first base 33 is provided with a chute 35, the upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com