Preparation method of magnetic-metal organic framework MOF material

A metal-organic framework and magnetic technology, which is applied in the field of materials, can solve the problems affecting the enrichment and enrichment capacity and detection sensitivity of phosphopeptides, and achieve the ideal enrichment recovery rate, large pore volume, and high selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

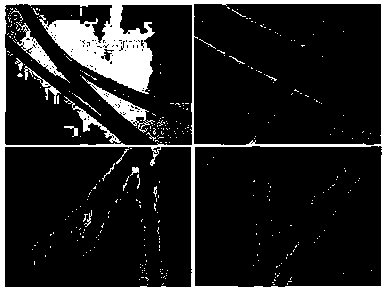

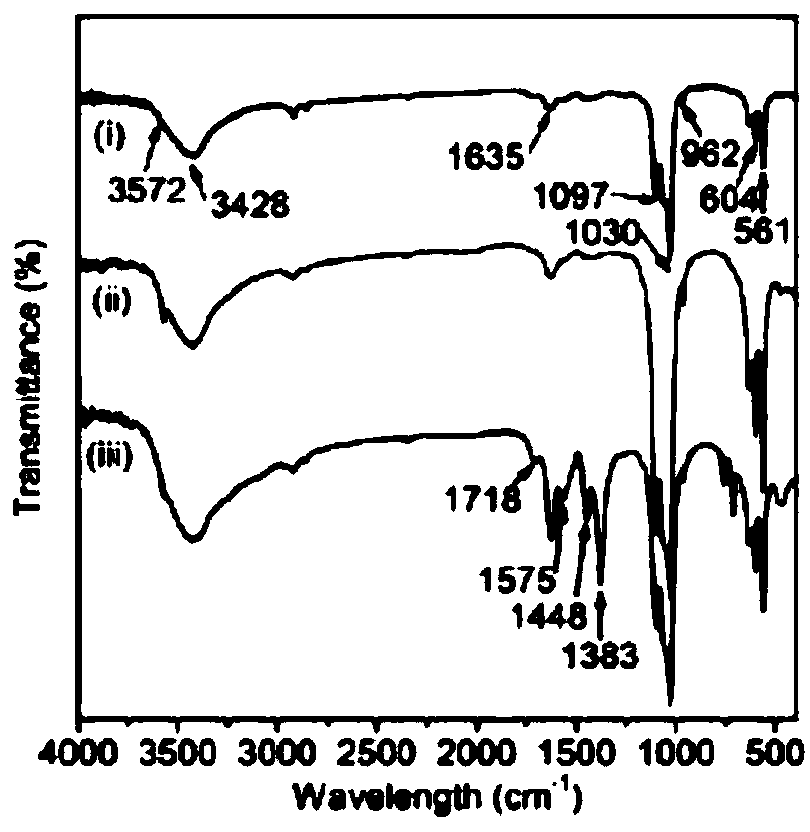

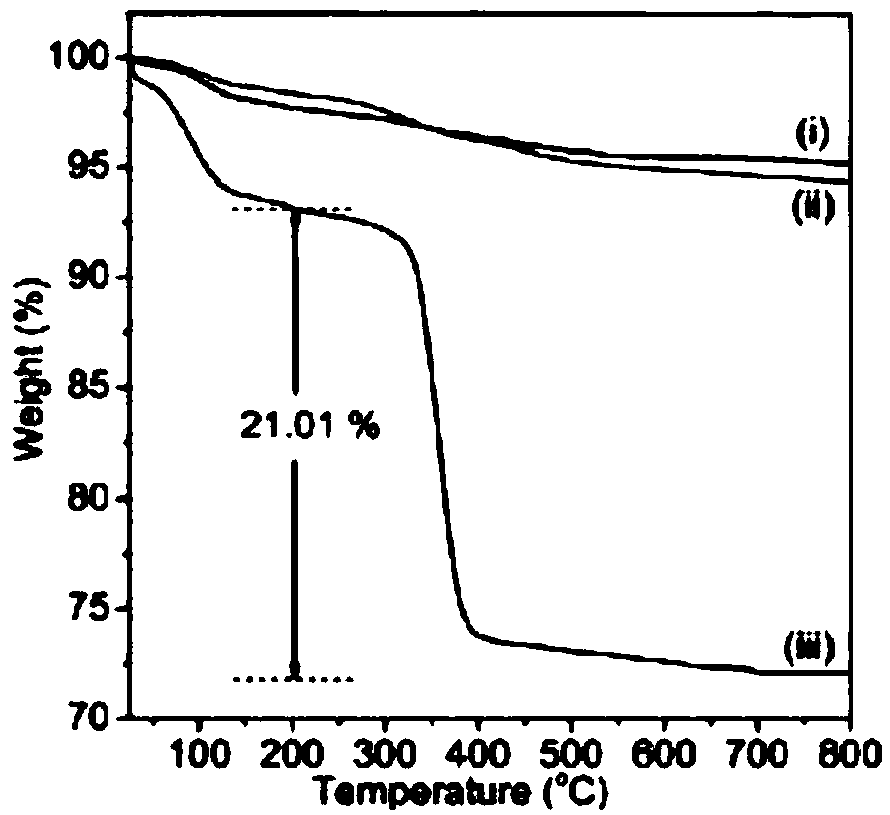

[0036]The embodiment of the present invention discloses a preparation method of a magnetic-metal organic framework MOF material, comprising the following steps: mixing oleic acid and ethanol under mechanical stirring, and then adding CaCl in sequence under vigorous stirring 2 Aqueous, aqueous NaOH and NaH 2 PO 4 ·2H 2 O aqueous solution, transferred to an autoclave, reacted at 160-200°C, washed to obtain hydroxyapatite nanowires; the hydroxyapatite nanowires and Fe(acac) were mixed under magnetic stirring 3 Disperse in triethylene glycol, then transfer to an autoclave, react at 200-240 ° C for 10-20 hours, wash, and obtain mag-HAP nanowires; alternately disperse the mag-HAP nanowires in FeCl 3 ·6H 2 In ethanol solution of O and 1,3,5-benzenetricarboxylic acid, incubate at 50-70°C for 10-20min respectively, in each cycle the intermediate is centrifuged at 3000-5000rpm, wash, repeat for 20-50 After several cycles of drying, a magnetic-metal organic framework MOF material was...

Embodiment 1

[0065] The mag-MOF nanofibers were prepared in three steps. First, inorganic hydroxyapatite nanowires were synthesized by solvothermal method as scaffolds. Specifically: 100 g of OA and 140 g of ethanol were mixed together under mechanical stirring. 200 mL of CaCl was added with vigorous stirring 2 (2.20 g) aqueous solution, 200 mL aqueous NaOH (10.0 g) and 100 mL NaH 2 PO 4 ·2H 2Aqueous O (2.80 g) was sequentially added to the mixture. The mixture was transferred to a 1 L Teflon-lined stainless steel autoclave and kept at 180 °C for 24 h. After naturally cooling to room temperature, the obtained HAP nanowire product was washed three times with ethanol and water, respectively.

[0066] Subsequently, the surface of the hydroxyapatite nanowires was functionalized with magnetic nanoparticles. Specifically: 1.0 g of hydroxyapatite nanowires and 0.5 g of Fe(acac) were mixed under magnetic stirring 3 Disperse in 180 mL TEG. The homogeneous mixture was transferred to six 100...

Embodiment 2

[0069] core-shell Fe 3 o 4 @MOF nanoparticles were prepared according to the prior art.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com