Knee joint prosthesis

A knee joint prosthesis and prosthesis technology, applied in the field of knee joint prosthesis, can solve the problems of fragility of ceramic femoral condyle prosthesis, reduced thickness of polymer inner lining, and high wear rate of tibial lining, so as to reduce fragmentation. risk, reducing metal ion precipitation, reducing the effect of friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

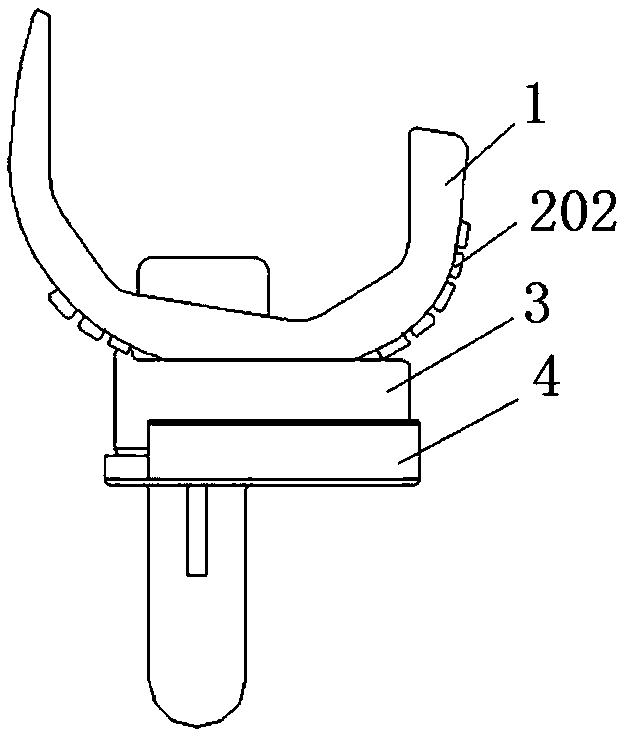

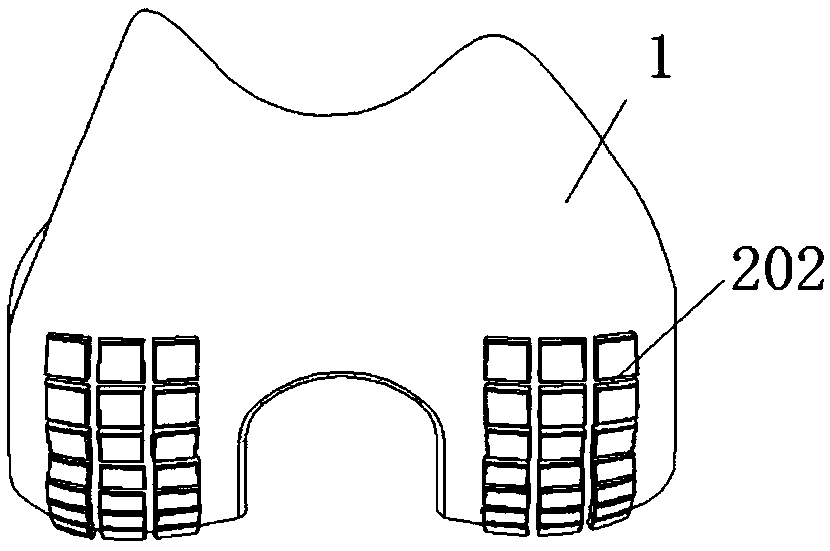

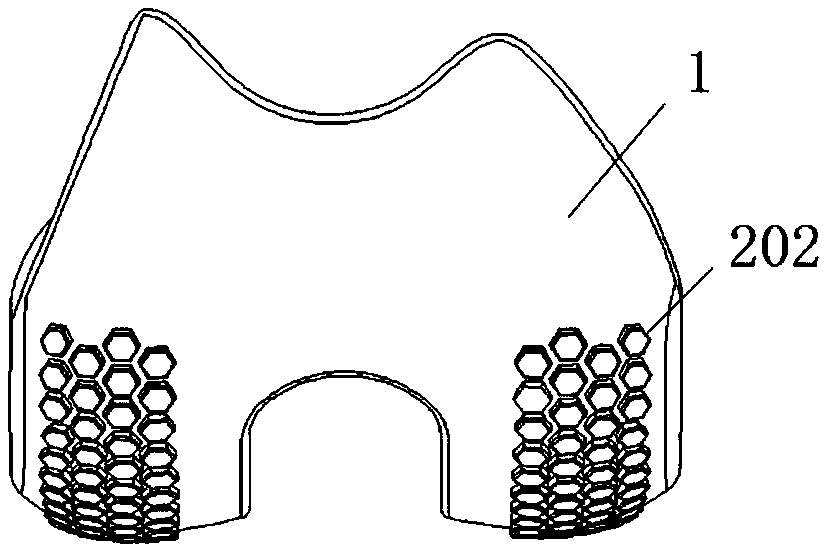

[0027] Knee joint prosthesis, including femoral condyle prosthesis, tibial liner, tibial plateau support, tibial liner is set on the tibial plateau support, the outer surface of the femoral condyle prosthesis corresponds to the upper surface of the tibial liner, and the outer surface of the femoral condyle prosthesis Or the upper surface of the tibial pad is provided with ceramic sheets for reducing the friction between the two. The ceramic sheets are a group, and a group of ceramic sheets are discretely distributed, which can be evenly or non-uniformly spaced. The non-uniform spacing arrangement can increase the contact area, thereby reducing the contact stress.

[0028] Among them, the inner surface of the femoral condyle prosthesis and the outer surface of the lower part of the tibial platea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com