Cathode film of lithium ion battery, preparation of the same, and application of the same

A lithium-ion battery and positive electrode film technology, applied in the field of lithium-ion battery positive electrode film and its preparation and application, can solve the problems of lithium-ion battery capacity attenuation, cycle efficiency reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The method for preparing the positive electrode film of the lithium battery of the present invention can mix the lithium ion supplement into the positive electrode material or slurry of the lithium battery and / or apply it on the positive electrode of the battery after the positive electrode of the conventional lithium battery is prepared. Specifically, the commonly used preparation methods include the following three:

[0077] (a1) provide a positive electrode material slurry, the slurry contains lithium intercalation transition metal oxide positive electrode material, lithium ion supplement, and conductive agent and binding agent; A positive electrode film is made by drying; or

[0078] or

[0079] (a3) Coating the lithium ion supplement on the surface of the dried lithium ion battery positive electrode, thereby forming a lithium battery positive electrode film containing the lithium ion supplement.

[0080] battery positive

[0081] The positive electrode of the ba...

Embodiment 1

[0091] Example 1 Preparation of Battery Positive Electrode 1

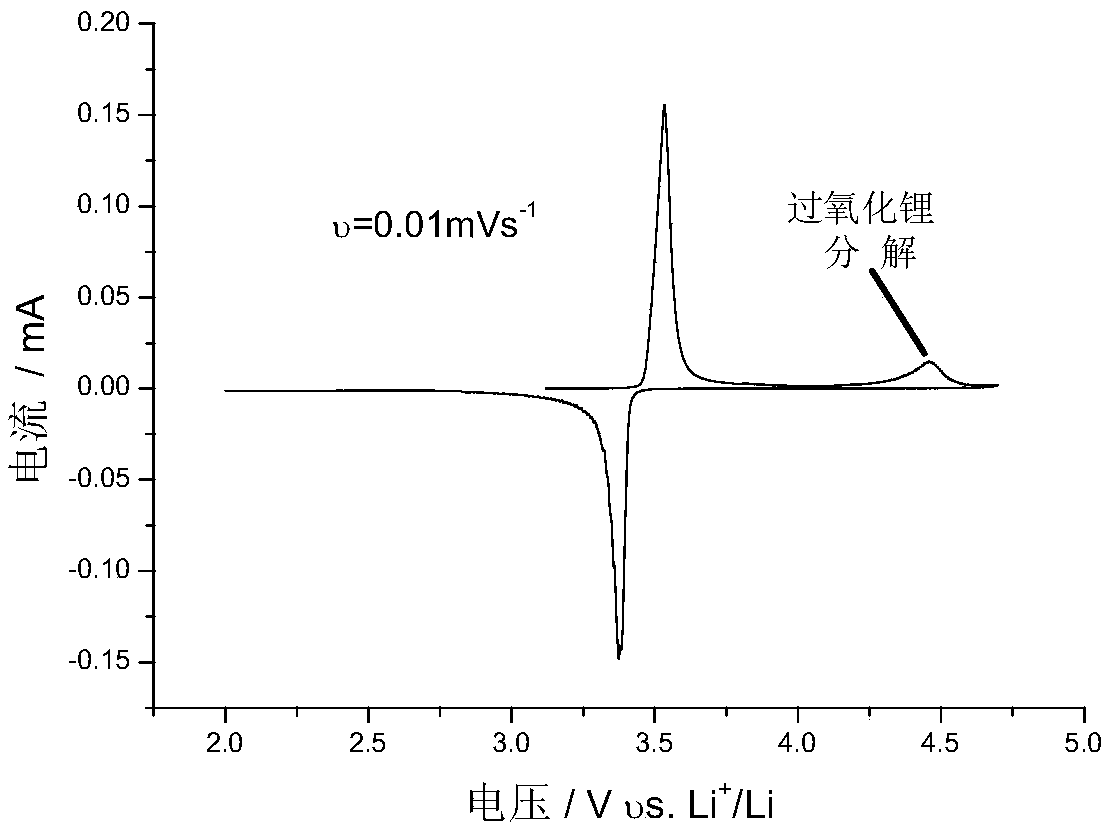

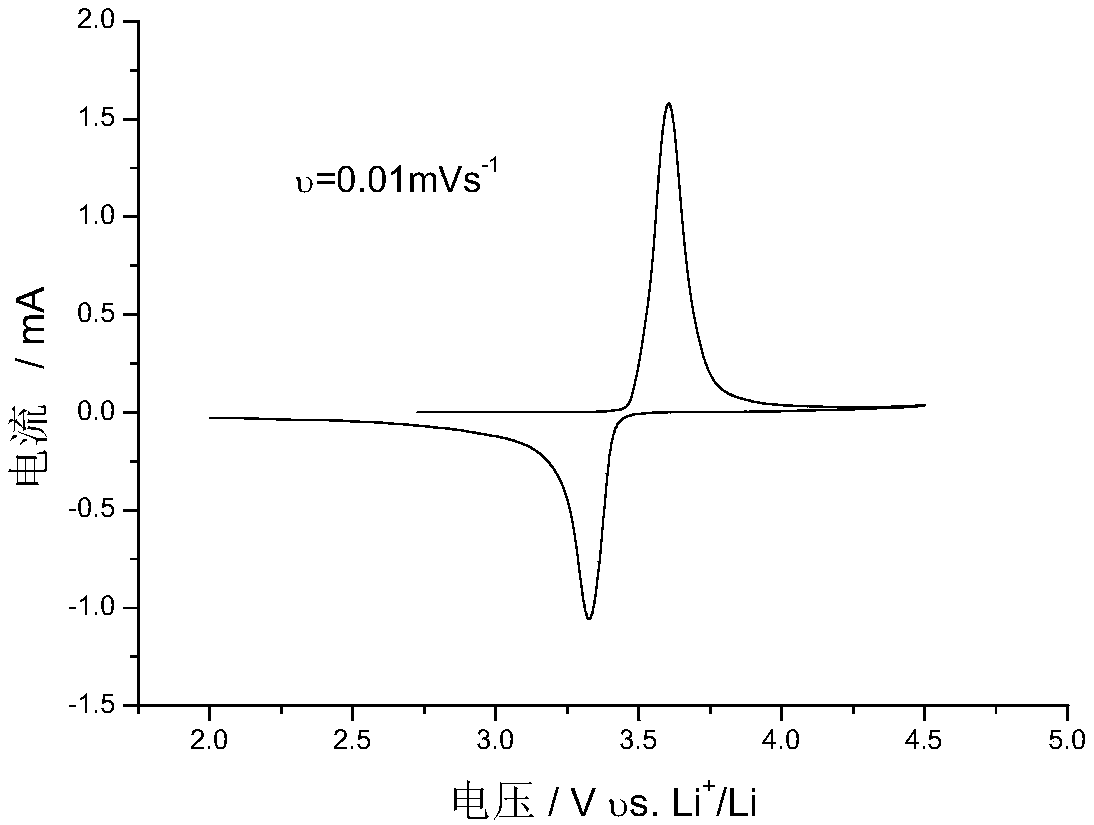

[0092] Lithium iron phosphate, a commercial lithium-ion battery anode material, is uniformly mixed with lithium ion supplement lithium peroxide, conductive agent acetylene black, and binder polyvinylidene fluoride (PVDF) in a nitrogen-methylpyrrolidone (NMP) solution.

[0093] The mass of lithium peroxide added is 1% of the mass of the positive electrode material lithium iron phosphate, and the mass ratios of the positive electrode material, acetylene black and binder are respectively 85:10:5, and then coated and pressed on the aluminum foil to obtain the positive electrode of the battery 1.

Embodiment 2

[0094] The preparation of embodiment 2 lithium battery 2 (half cell)

[0095] The positive electrode 1 of the battery is assembled into a CR2032 button lithium battery 2 with a metal lithium sheet as the positive electrode, a solution of ethylene carbonate and dimethyl carbonate of 1mol / L lithium hexafluorophosphate as the electrolyte, and polyethylene with a thickness of 20 microns as the diaphragm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com