Flexible photovoltaic n-type film high temperature preparation method

An n-type film and flexible technology, which is applied in the field of high-temperature preparation of flexible photovoltaic n-type films, can solve the problems of limited device process preparation conditions and structural design, and achieve the effects of strong plasticity, wide selection range, and excellent flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

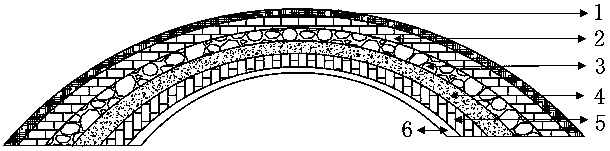

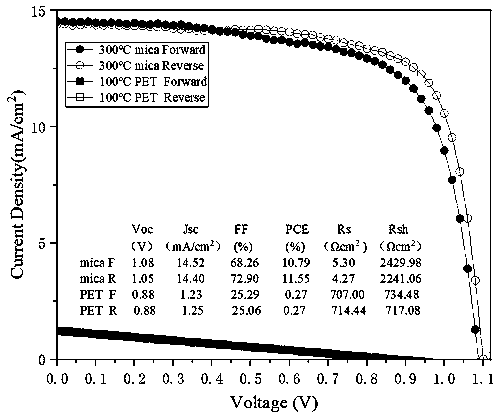

[0019] The preparation process of the solar cell is as follows: the flexible substrate is mica, a layer of ITO is magnetron sputtered on the substrate, and the electron transport layer SnO is prepared by uniform spin coating. 2 , the rotation speed is 3000r / min, and the time is 30 seconds. After the spin coating is completed, the substrate is heated on a heating panel at 300°C for 30 minutes, and then it is placed in a glove box to cool. After that, in the glove box, spin-coat calcium titanium Mineral photoelectric conversion layer, preferably CsFAMAPbI 3-x Br x , after filtering the prepared perovskite solution, heat and stir with a magnetic stirrer. At the same time, the anisole solution was filtered, and when the perovskite was spin-coated, the anisole was rinsed, and then annealed under a heating panel at 110°C for 20 minutes. The substrate is cooled in the glove box. After the substrate is cooled to room temperature, the hole transport layer Spiro-OMeTAD solution is spi...

Embodiment 2

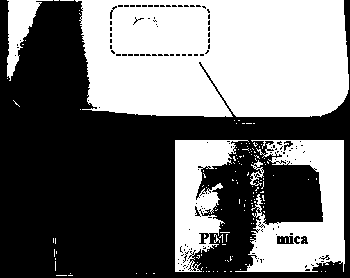

[0021] Spin-coating SnO on PET / ITO 2 , followed by annealing at 300°C, complete bubble formation (such as figure 2 ), and then the battery device was prepared according to the experimental procedure of Example 1, and the device completely failed.

Embodiment 3

[0023] Spin-coating SnO on PET / ITO 2 , and then annealed at 100°C, and then prepared a battery device according to the conditions of Example 1, and the assembled battery efficiency was 0.27% (such as image 3 ). It shows that in the process of battery preparation, PET is deformed after being heated for many times, which affects the efficiency.

[0024] The perovskite solar cells prepared with flexible substrates have the properties of high temperature resistance, transparency, and repeated bending. The preparation process is simple, the price is cheap, there is no pollution to the environment, the shape has strong plasticity, and the application range is wider.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com