Device for ammonia gas fountain experiment

An experiment and fountain technology, which is applied in the direction of educational appliances, instruments, teaching models, etc., can solve the problems of inability to achieve the integration of preparation and experiment, reduce the practicality of the device, and reduce the efficiency of the experiment, so as to facilitate the promotion and use and prolong the service life , Improve the effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

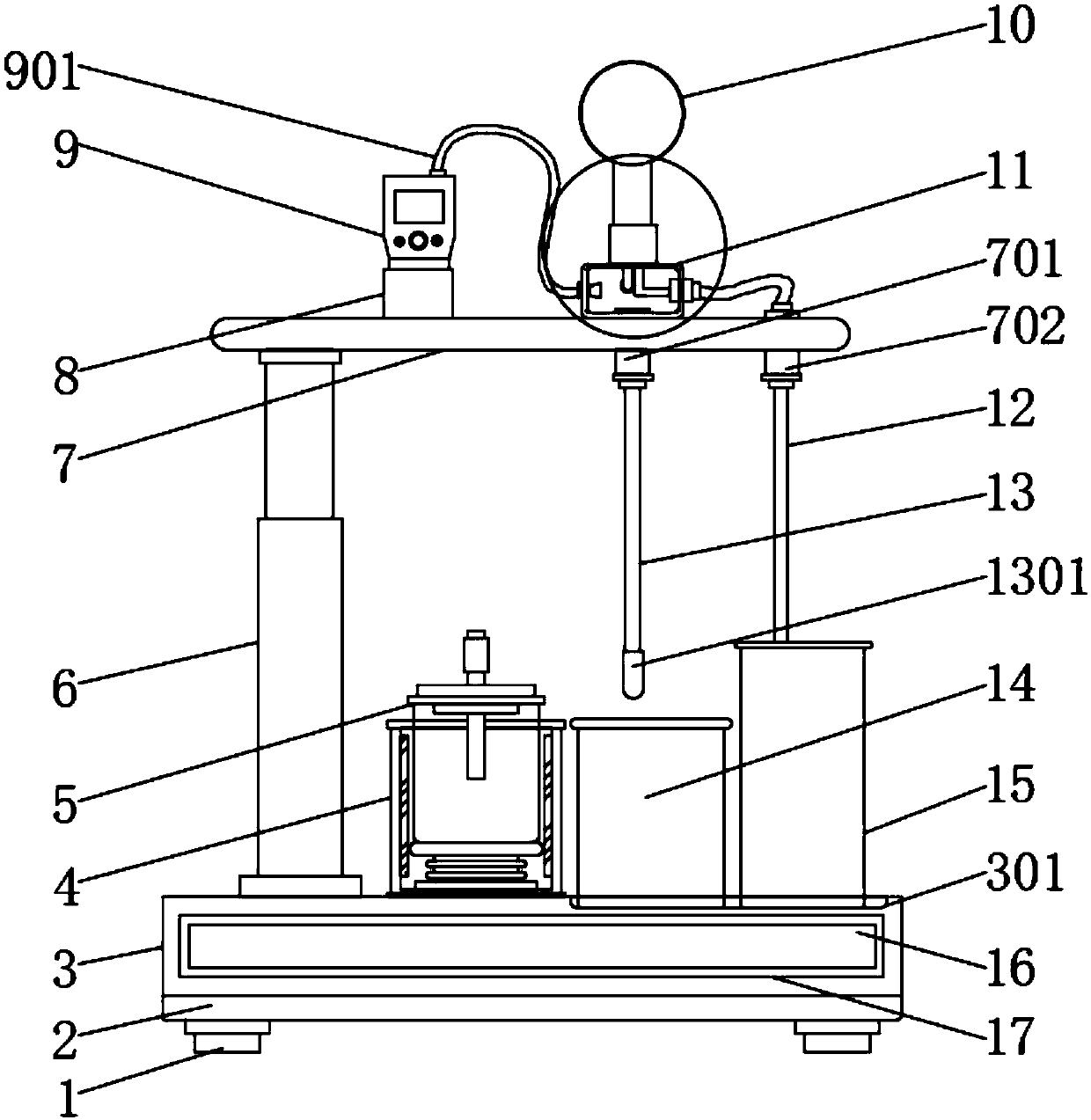

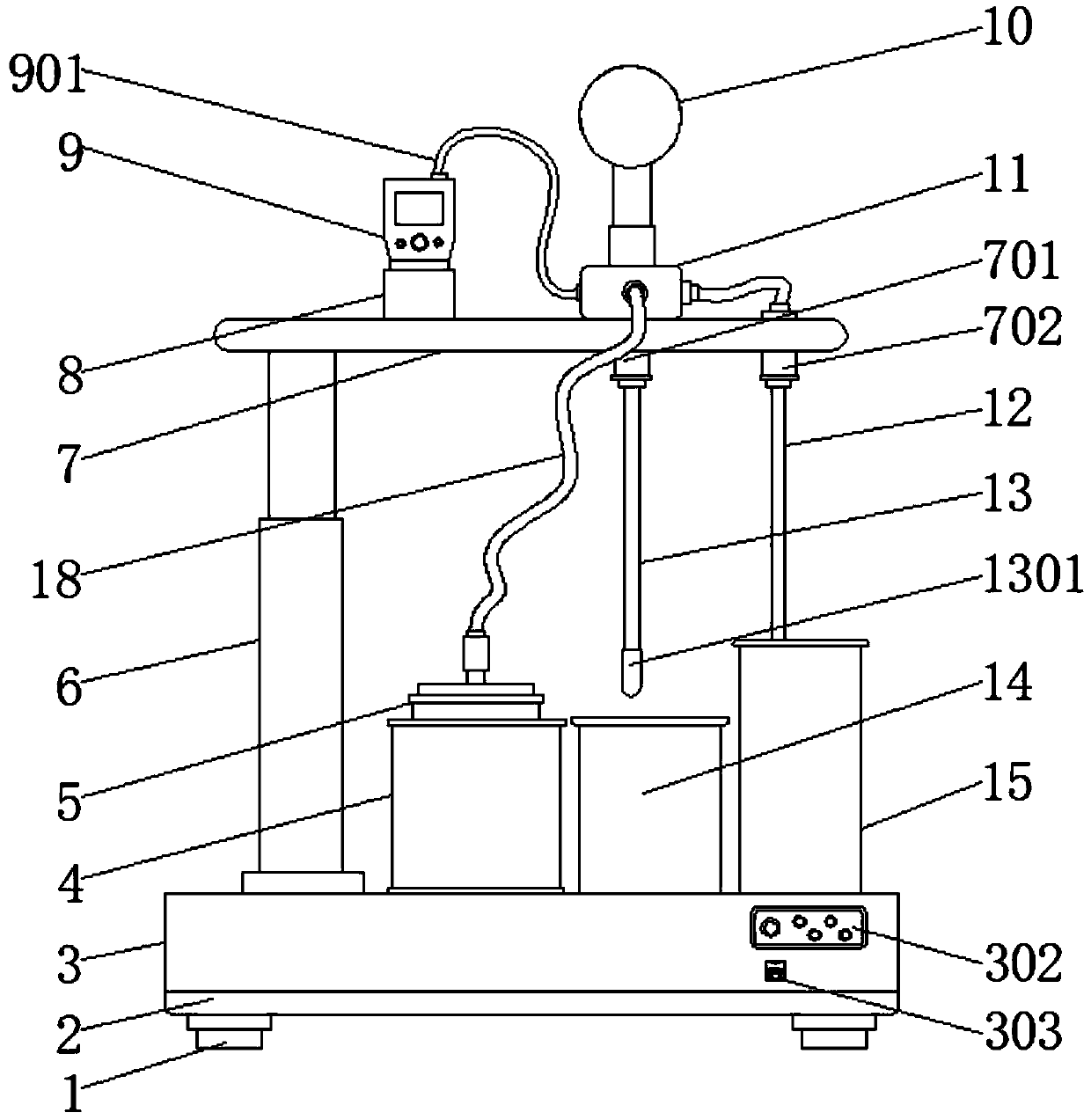

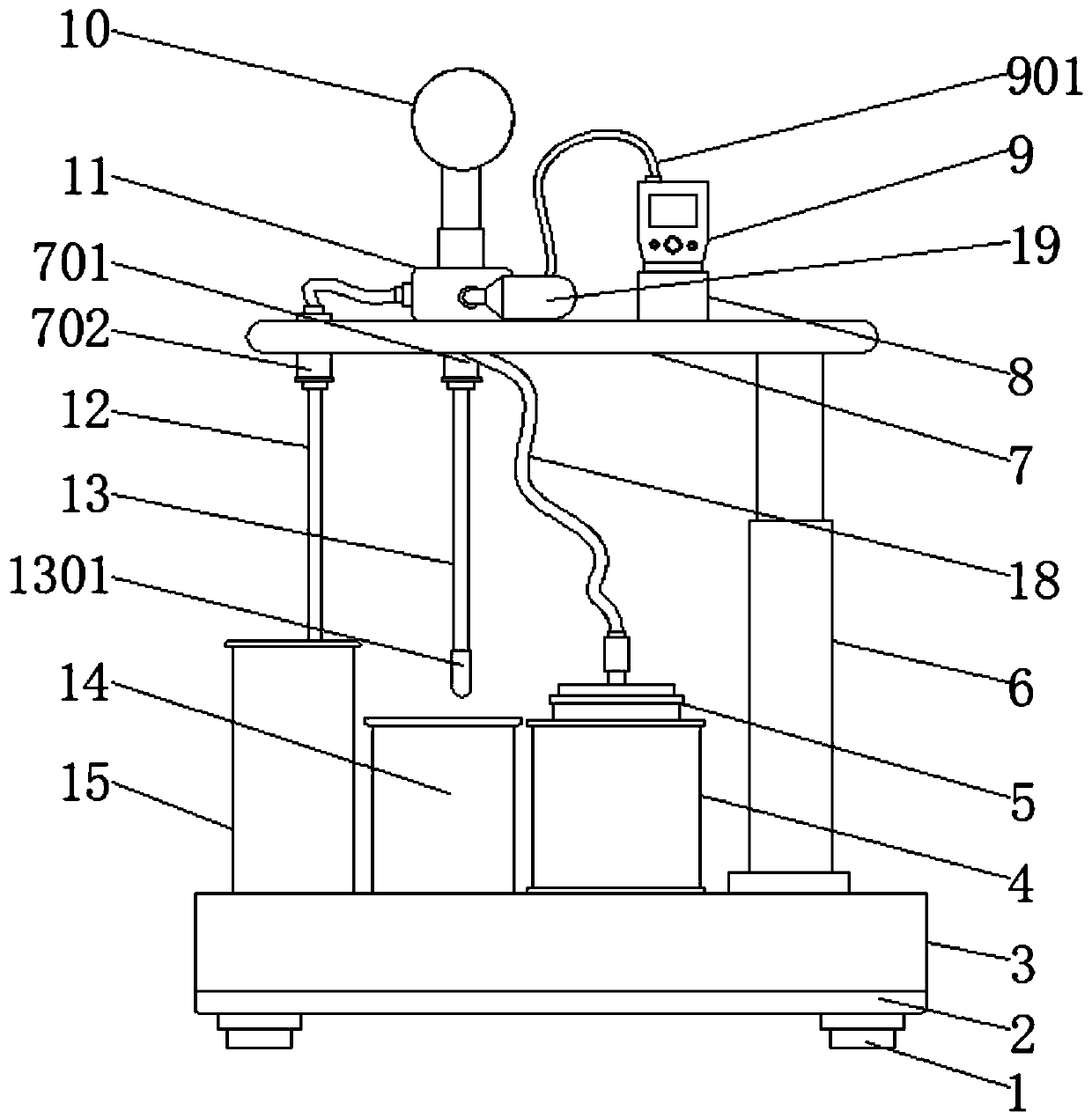

[0025] see Figure 1-5 , an embodiment provided by the present invention: a device for ammonia fountain experiments, including a base 3 and a top plate 7, a detection chamber 11 is fixedly installed on the top of the top plate 7, and the detection chamber 11 and the top plate 7 are installed by screws Fixed, the front of the detection chamber 11 communicates with the third glass tube 22 through the first rubber hose 18, the bottom of the detection chamber 11 is fixedly equipped with the second glass conduit 13 corresponding to the second beaker 14, the top plate of the second glass conduit 13 7 is fixedly installed with the first glass conduit 12 corresponding to the third beaker 15, and the first glass conduit 12 communicates with the detection chamber 11 through the second rubber hose 26, and the inside of the detection chamber 11 is installed with a glass tube extending into the flask 10. The fourth glass conduit 25, and the fourth glass conduit 25 communicates with the sec...

Embodiment 2

[0028]This embodiment is further improved on the basis of Embodiment 1. A control switch 302 and a power jack 303 are fixedly installed on the front of the base 3 respectively. The control switch 302 is connected to the electric telescopic rod 6 and the heating plate 21 respectively The electrical connection is convenient for the control operation, and the power socket 303 is electrically connected with the battery 16 to charge the battery 16 .

[0029] Meanwhile, the bottom of the second glass conduit 13 is covered with a rubber sealing sleeve 1301 . In the embodiment, the rubber sealing sleeve 1301 can seal the second glass conduit 13 to ensure the sealing performance of the device inside the experiment, and the entry of outside air ensures the quality of the experiment.

Embodiment 3

[0031] This embodiment is further improved on the basis of Embodiment 2, and the inner wall of the heating cylinder 4 is fixedly installed with an asbestos layer 401 . In the embodiment, the asbestos layer 401 improves the heat insulation effect of the heating cylinder 4, avoids the situation that personnel's hands are burned during the experiment, and ensures the safety during the experiment.

[0032] The detection chamber 11 communicates with the second glass conduit 13 through a first connecting pipe 701 , and the second rubber hose 26 communicates with the first glass conduit 12 through a second connecting pipe 702 . In the embodiment, the first connecting pipe 701 and the second connecting pipe 702 play a good connecting role, which is convenient for the staff to disassemble and clean.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com