A test device for rapid heating of inert gas without pollution

An inert gas, rapid heating technology, used in measuring devices, fluid heaters, heat storage heaters, etc., can solve the problems of long preparation time, slow temperature rise, and great influence on test results, and achieve fast heating speed and working fluid. High purity and rapid heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

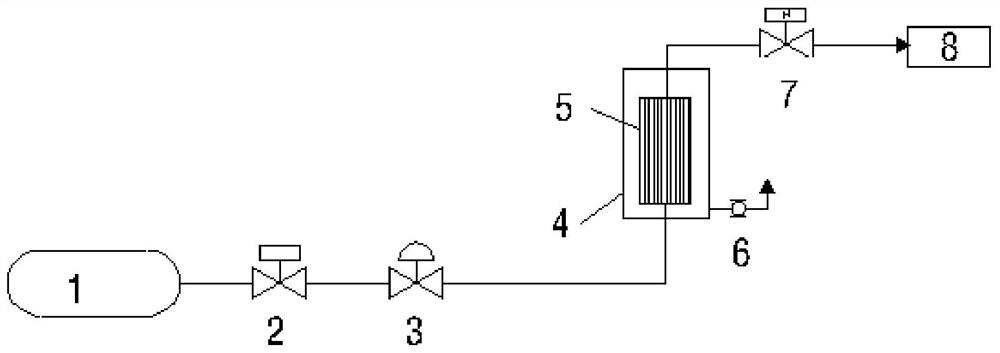

[0024] This embodiment provides a test device for quickly heating an inert gas without pollution, see the attached figure 1 , including: inert gas source 1, switching valve 2, regulating valve 3, graphite regenerator 5, electromagnetic induction coil, vacuum pump 6, pressure shell 4, high temperature valve 7 and gas unit 8;

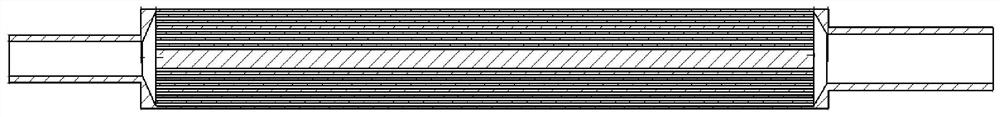

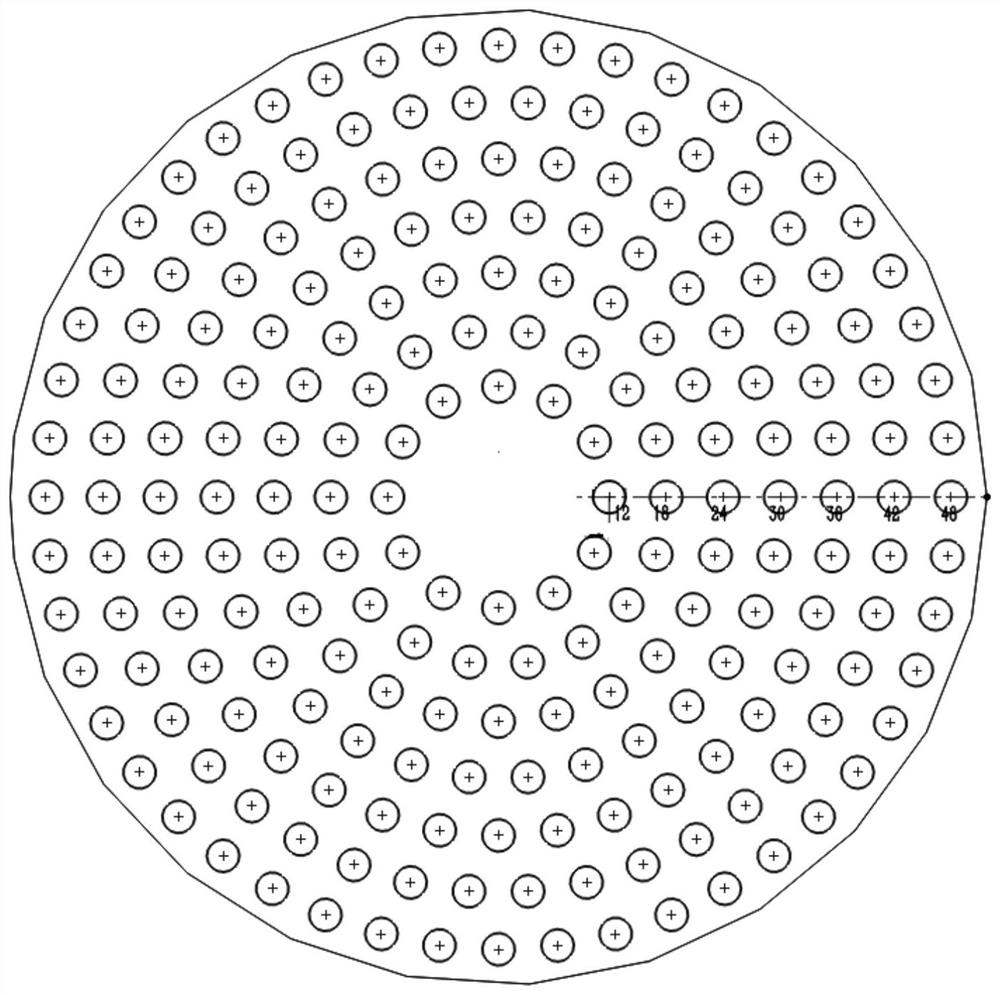

[0025] See attached figure 2 with image 3 , the graphite regenerator 5 is composed of a cylindrical body and an air inlet channel and an air outlet channel respectively arranged at two ends of the cylindrical body; the cylindrical body is provided with more than two axial air holes; the axial air holes The two ends communicate with the air inlet channel and the air outlet channel respectively; the axial pores are evenly distributed in the circumferential direction for more than two turns; the graphite regenerator 5 is wound with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com