Method for detecting compression loss of cylinders of multi-cylinder combustion engine

A multi-cylinder internal combustion engine, compression loss technology, applied in the direction of internal combustion engine testing, electrical control, mechanical equipment, etc., can solve the problems of measurement convincingness, variation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

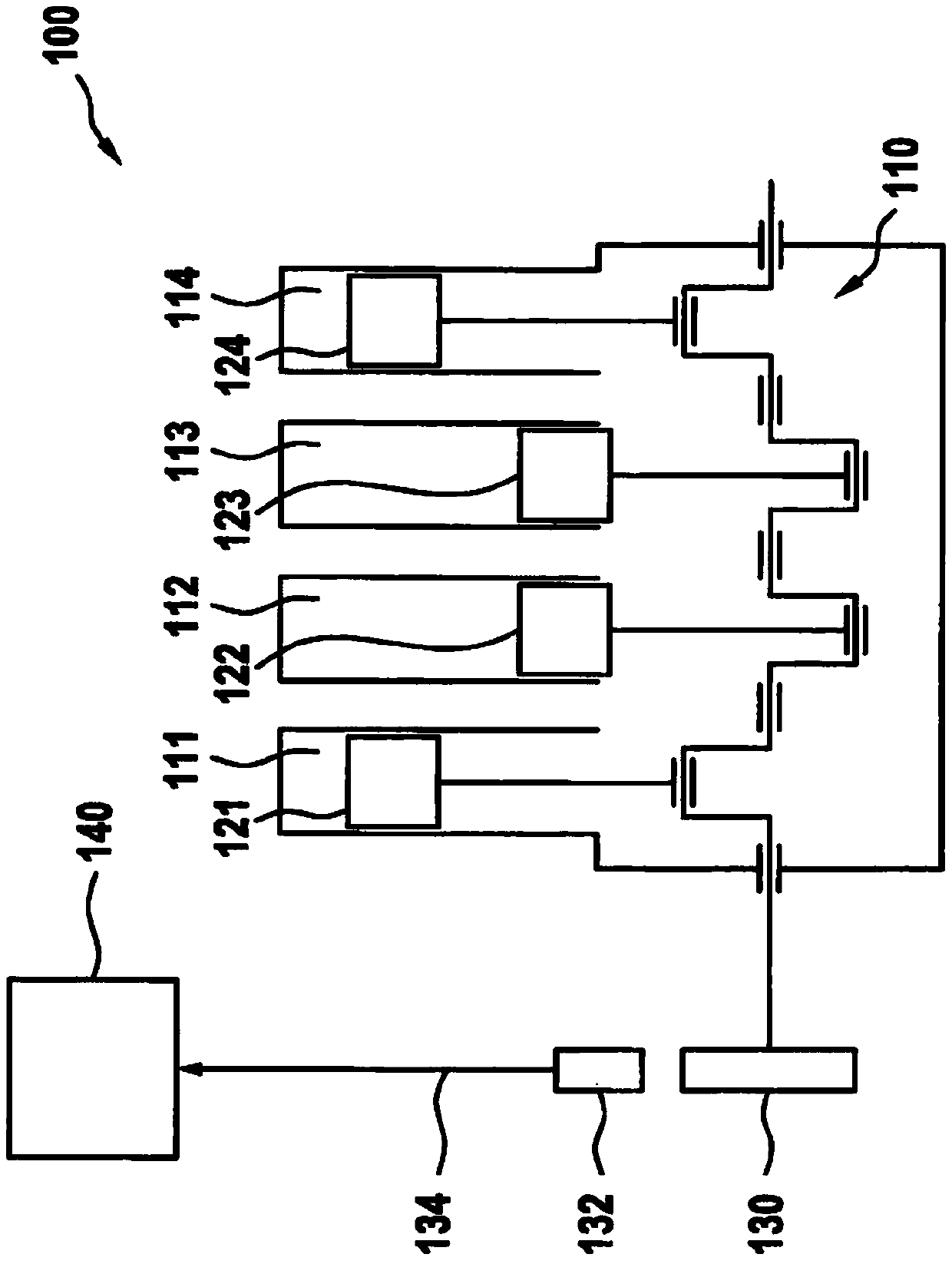

[0038] exist figure 1 An internal combustion engine is shown schematically in FIG. 1 and is designated 100 , which is designed as a four-cylinder four-stroke engine.

[0039] The internal combustion engine 100 has four cylinders 111 , 112 , 113 , 114 which are movably sealed by pistons 121 , 122 , 123 , 124 respectively. The gas forces acting on the pistons 121 , 122 , 123 , 124 are transmitted to the crankshaft 110 .

[0040] Sensor wheel 130 is connected to crankshaft 110 in a rotationally fixed manner. In particular, markings are arranged equidistantly along the circumference of sensor wheel 130 . These marks can be sampled by means of a receiver 132 , eg a magnetic sensor, and a measurement signal 134 , eg a voltage signal, can be determined by a controller 140 .

[0041] From this measurement signal 134 the controller 140 can determine the point in time at which the marking passes the receiver 132 as the so-called tooth time. The segment time can be determined as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com