Production equipment for reducing content of carbon in nickel or nickel alloy

A production equipment and nickel alloy technology, which is applied in the field of nickel and nickel alloy old material recycling, to achieve the effect of simple processing, low cost and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

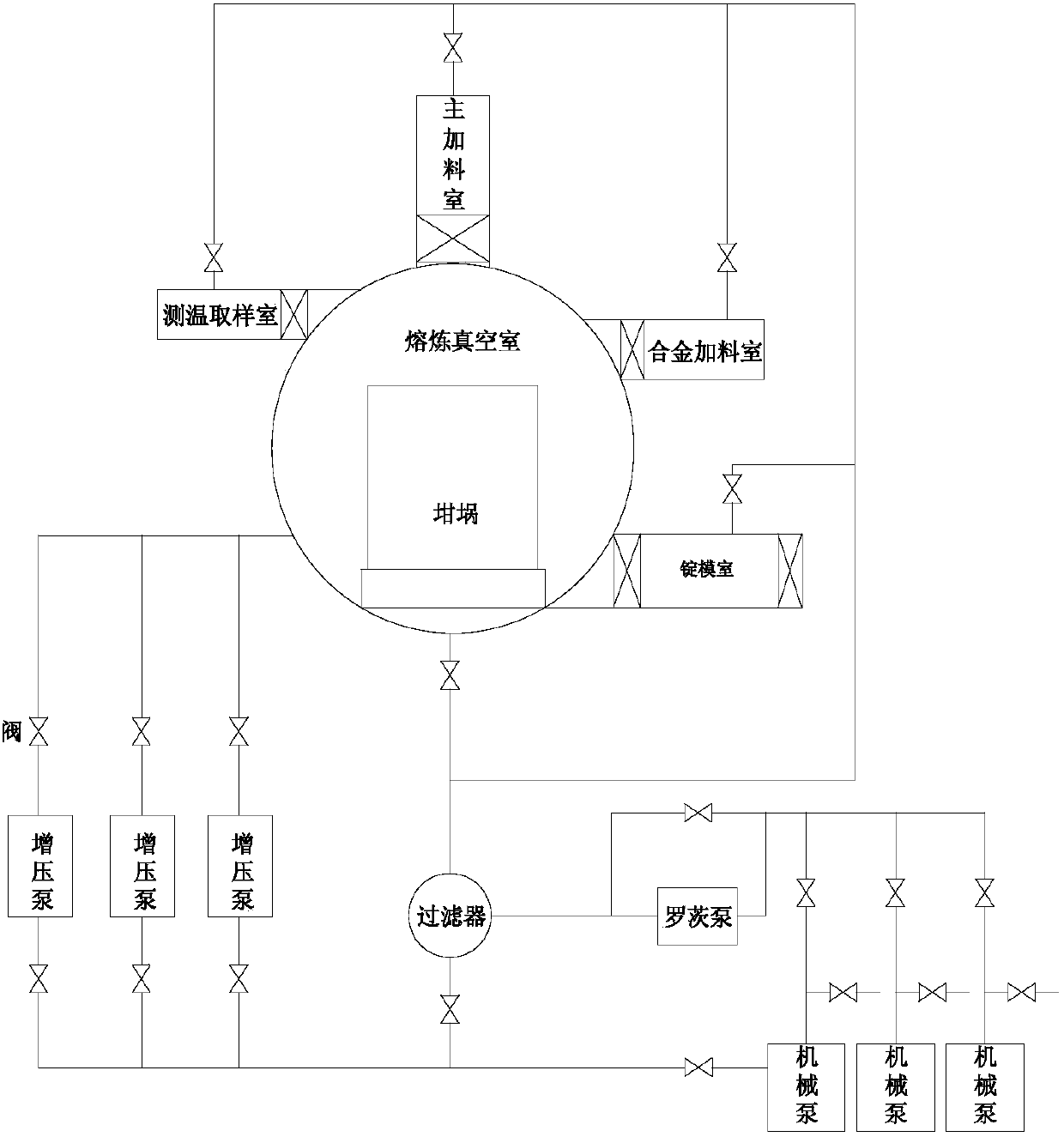

[0028] Such as figure 1 Shown, the present invention reduces the production equipment of carbon content in nickel or nickel alloy, mainly comprises: temperature measuring sampling room, main feeding room, smelting vacuum room, alloy feeding room, crucible, ingot mold room, booster pump, valve, filter device, Roots pump, mechanical pump, etc., the specific structure is as follows:

[0029] The melting vacuum chamber is respectively connected with the sampling chamber, the main feeding chamber, the alloy feeding chamber and the ingot mold chamber. The crucible is set in the melting vacuum chamber, and the gas outlets of the sampling chamber, the main feeding chamber, the alloy feeding chamber and the ingot mold chamber are respectively connected by pipelines. To the filter, the air outlet of the filter is connected with the booster pump and the mechanical pump respectively, and the air outlet of the mechanical pump is respectively communicated with the air inlet of the filter th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com