A kind of graphene/nano titanium dioxide composite material and its preparation method and application

A nano-titanium dioxide and composite material technology, which is applied in the field of graphene/nano-titanium dioxide composite materials and their preparation, can solve problems such as unfavorable industrial production, potential safety hazards, long reaction time, etc., and achieves improved stability and service life. The effect of shortened production cycle and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

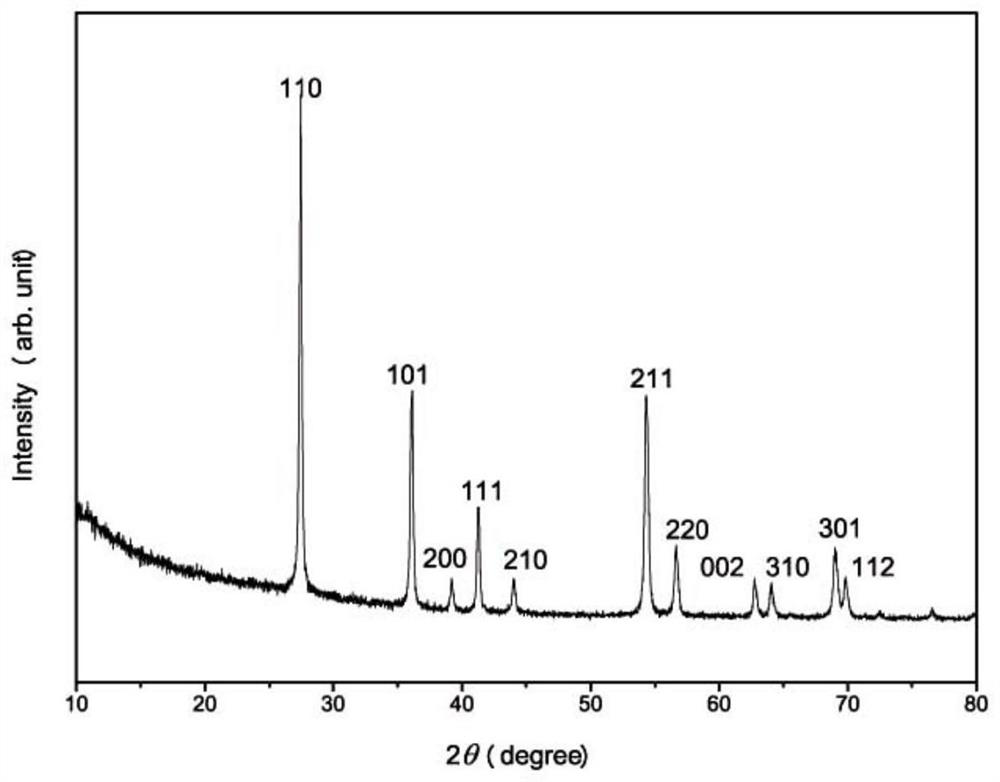

Image

Examples

preparation example Construction

[0036] The embodiment of the present invention provides a kind of preparation method of graphene / nano titanium dioxide composite material, comprises the following steps:

[0037] Step (1): Weighing nano-titanium dioxide nano-TiO 2 and a polar solvent, and disperse the weighed nano-titanium dioxide in a polar solvent under stirring conditions to obtain a nano-titanium dioxide suspension;

[0038] Step (2): dispersing graphene oxide GO in water to prepare a graphene precursor solution;

[0039] Step (3): Add the graphene precursor solution dropwise into the nano-titanium dioxide suspension under stirring conditions to prepare graphene and nano-titanium dioxide composite GO@nano-TiO 2 Dispersions;

[0040] Step (4): Continue to stir for a period of time and then stop, let it stand naturally, separate, and obtain the lower layer of precipitate, dry the precipitate to obtain GO@nano-TiO 2 Complex;

[0041] Step (5): The graphene and nano-titanium dioxide composite is reduced fo...

Embodiment 1

[0060] The present embodiment provides a kind of graphene / nano titanium dioxide composite material, and its preparation method comprises the steps:

[0061] (1) nano-TiO 2 Preparation of suspension

[0062] Press m(nano-TiO 2 ): m (polar solvent) = 1:50 by weighing rutile phase nano-titanium dioxide (average particle size 100nm) and isopropanol, and weighing the nano-TiO 2 Dispersed in isopropanol and stirred at a high speed of 200rpm to prepare nano-TiO 2 suspension;

[0063] (2) Preparation of graphene precursor solution

[0064] Measure the graphene oxide (oxygen mass content is 40%) aqueous dispersion liquid of 2g / L, place ultrasonic dispersion 2h in 600W ultrasonic cell pulverizer, make graphene precursor solution; Wherein the quality of graphene oxide is step ( 1) Medium nano-TiO 2 1% of mass;

[0065] (3) GO@nano-TiO 2 Preparation of complex

[0066] Under high-speed stirring at 500rpm, the graphene precursor solution was slowly added dropwise to the nano-TiO a...

Embodiment 2

[0071] (1) nano-TiO 2 Preparation of suspension

[0072] Press m(nano-TiO 2 ): m (polar solvent) = 1:100 Weigh the anatase phase nano-titanium dioxide (average particle size 100nm) and ethanol, the weighed nano-TiO 2 Dispersed in ethanol and stirred at a high speed of 300rpm to prepare nano-TiO 2 suspension;

[0073] (2) Preparation of graphene precursor solution

[0074] Measure the graphene oxide (oxygen mass content is 40%) aqueous dispersion liquid of 5g / L, place ultrasonic dispersion 2h in 1800W ultrasonic cell pulverizer, make graphene precursor solution; Wherein the content of graphene oxide is step ( 1) Medium nano-TiO 2 2wt% of the content;

[0075] (3) GO@nano-TiO 2 Preparation of complex

[0076] Under high-speed stirring at 800rpm, the graphene precursor solution was slowly added dropwise to the nano-TiO at a rate of 300 drops / min. 2 In the suspension, GO@nano-TiO was prepared 2 Composite dispersion; continue to stir for 30 minutes, then stop, and let it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com