Flame retardant polyurethane sponge, preparation method and application thereof

A polyurethane sponge and sponge technology, which is applied in the field of material modification, can solve the problems of damaging the mechanical properties of polymers, the flame retardancy of materials has not yet been found, and the inability to achieve self-extinguishing, so as to improve mechanical strength, reduce mass/energy transfer, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

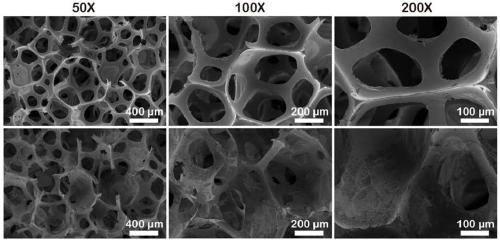

[0038] (1) Cut the commercial polyurethane sponge into a size of 2.5cm×2.5cm×2.5cm, wash it with acetone under ultrasonic conditions for 20min, volatilize in the air for 6h until the solvent is completely evaporated, then wash it with deionized water for 5min, and place it in an oven at 50°C Dry for 120min;

[0039] (2) Weigh 1g of halloysite nanotubes (length 200-500nm, outer diameter 50-60nm, inner diameter 10-20nm, origin Shanxi) in 100mL deionized water, ultrasonically disperse for 30min to obtain halloysite nanotube water Dispersions;

[0040] (3) Soak the sponge completely in the halloysite nanotube aqueous dispersion, squeeze the sponge 5 times by hand until no bubbles are produced in the sponge, and stir for 60 minutes (rotating speed 200 rpm) until the sponge absorbs enough dispersion;

[0041] (4) Take out the sponge, place it in an oven at 80°C, dry it for 4 hours, and turn the sponge over by hand every half an hour to avoid the uneven coating thickness of the hall...

Embodiment 2

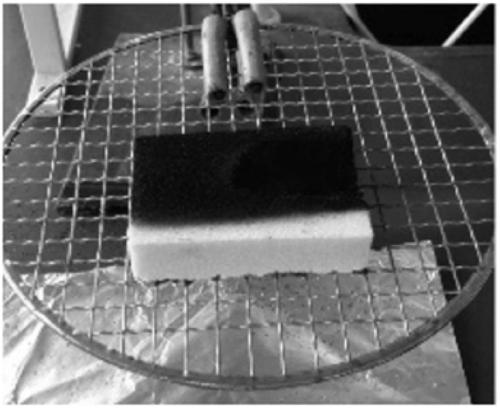

[0045] (1) Cut the commercial polyurethane sponge into a size of 10cm×10cm×3cm, wash it with ethanol under ultrasonic conditions for 30 minutes, volatilize it in the air for 4 hours until the solvent evaporates completely, then wash it with deionized water for 10 minutes, and dry it in an oven at 60°C for 150 minutes;

[0046] (2) Weigh 5g of halloysite nanotubes (500-1000nm, 60-70nm in outer diameter, 20-30nm in inner diameter, produced in Hunan) in 100mL of deionized water, stir and disperse for 60min to obtain water dispersion of halloysite nanotubes liquid;

[0047] (3) Soak the sponge completely in the halloysite nanotube aqueous dispersion, squeeze the sponge 6 times with tweezers until no bubbles are produced when squeezing the sponge, and ultrasonicate for 120min (1000W) until the sponge absorbs enough dispersion;

[0048] (4) Take out the sponge, place it in an oven at 100°C, dry it for 3 hours, and turn the sponge over every 5 minutes by hand to avoid the uneven coat...

Embodiment 3

[0052] (1) Cut the commercial polyurethane sponge into a size of 20cm×20cm×5cm, wash it with ethanol under ultrasonic conditions for 40min, volatilize in the air for 6h until the solvent evaporates completely, then wash it with deionized water for 15min, and dry it in an oven at 50°C for 180min;

[0053] (2) Weigh 4g of halloysite nanotubes (300-800nm in length, 70-80nm in outer diameter, 10-20nm in inner diameter, produced in Hunan) in 100mL deionized water, stir and disperse for 120min to obtain halloysite nanotube water Dispersions;

[0054] (3) Soak all the sponge in the halloysite nanotube aqueous dispersion, squeeze the sponge 5 times with tweezers until no bubbles are produced in the sponge, and stir for 150min (rotating speed 400rpm) until the sponge absorbs enough dispersion;

[0055] (4) Take out the sponge, place it in an oven at 90°C, dry it for 6 hours, and turn the sponge mechanically every 10 minutes to avoid the uneven coating thickness of the halloysite nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com