Preparation method of ethylene-vinyl alcohol copolymer

A technology of vinyl alcohol copolymer and ethylene, which is applied in the field of copolymers, can solve the problems of easy yellowing of resin at high temperature, etc., and achieve the effects of improving heat resistance, improving alcoholysis efficiency, and increasing alcoholysis degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of ethylene-vinyl alcohol copolymer specifically carries out according to the following steps:

[0032] A. Copolymerization

[0033] 20 parts of methanol, 150 parts of vinyl acetate, 0.005 parts of azobisisobutyronitrile and ethylene are used as raw materials to carry out copolymerization reaction, the pressure in the kettle feeding ethylene is controlled at 6 MPa, the temperature of the copolymerization reaction is 40 °C, and the pressure is 6.5 MPa. The reaction time is 2.0 hours;

[0034] B. Alcoholysis

[0035] Add sodium hydroxide to the solution obtained in step A twice to carry out the alcoholysis reaction, the ratio of the amount of sodium hydroxide in the first time period to the amount of sodium hydroxide in the second time period is 2:1, the first time period and the second time period The ratio of the segment is 0.5:1, and the molar ratio of sodium hydroxide to the ethylene-vinyl acetate copolymer obtained by copolymerization is 0.3:...

Embodiment 2

[0042] The preparation method of ethylene-vinyl alcohol copolymer specifically carries out according to the following steps:

[0043] A. Copolymerization

[0044] Copolymerize with 100 parts of ethanol, 60 parts of vinyl acetate, 1 part of azobisisoheptanonitrile and ethylene as raw materials, control the pressure in the kettle feeding ethylene to 2.5 MPa, the temperature of the copolymerization reaction is 40 ° C, and the pressure is 2.0 MPa , the reaction time is 8.0 hours;

[0045] B. Alcoholysis

[0046] Add potassium hydroxide to the solution obtained in step A twice to carry out the alcoholysis reaction, the ratio of the amount of potassium hydroxide in the first time period to the amount of potassium hydroxide in the second time period is 0.8:1, the first time period and the second time period The ratio of segment is 1.5:1, and the molar ratio of potassium hydroxide and the ethylene-vinyl acetate copolymer obtained by copolymerization is 0.01:1;

[0047] C. Post-proc...

Embodiment 3

[0053] The preparation method of ethylene-vinyl alcohol copolymer specifically carries out according to the following steps:

[0054] A. Copolymerization

[0055]Use 40 parts of n-propanol, 90 parts of vinyl acetate, 0.05 parts of dimethyl azobisisobutyrate and ethylene as raw materials to carry out copolymerization reaction, control the pressure in the kettle feeding ethylene to 4.2 MPa, and the temperature of the copolymerization reaction to be 50 °C , the pressure is 4.5MPa, and the reaction time is 6.0 hours;

[0056] B. Alcoholysis

[0057] Add sodium methylate to the solution that step A obtains twice and carry out alcoholysis reaction, the sodium methylate consumption of the first time period and the sodium methylate consumption ratio of the second time period are 1.2:1, the initial time of alcoholysis and the late time ratio of alcoholysis are 1:1, the molar ratio of sodium methoxide to the ethylene-vinyl acetate copolymer obtained by copolymerization is 0.05:1;

[...

PUM

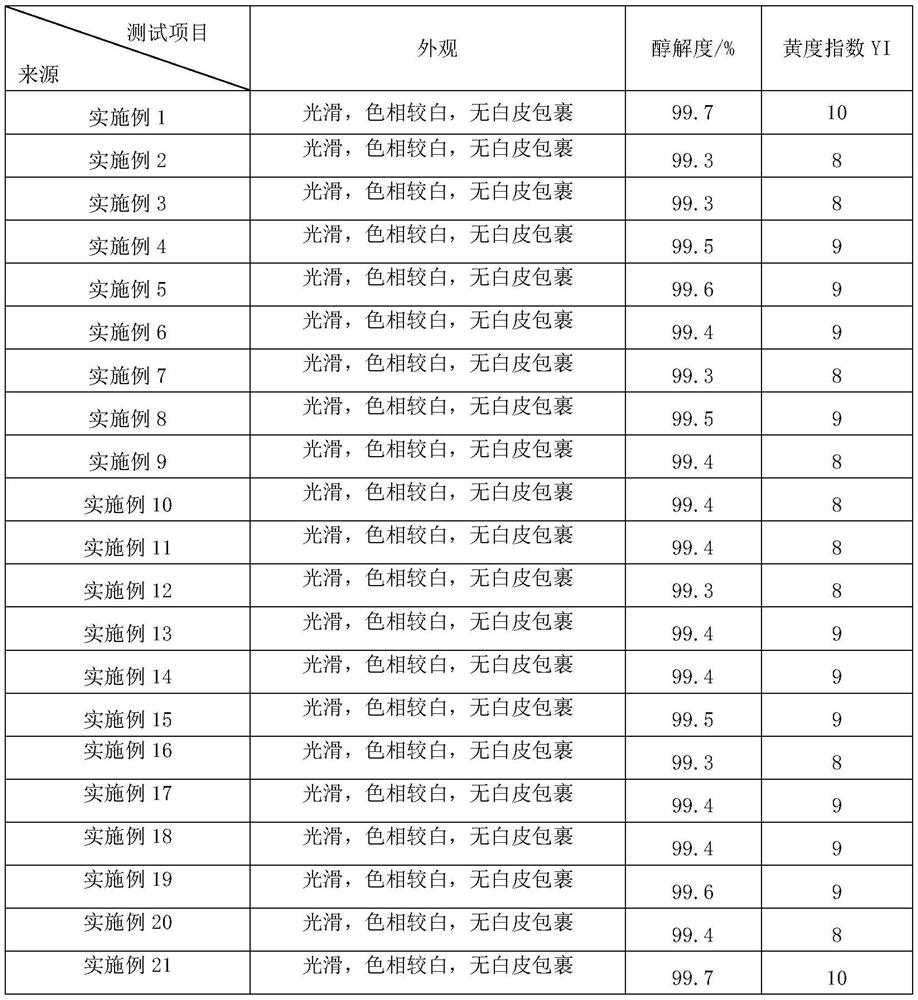

| Property | Measurement | Unit |

|---|---|---|

| yellowness index | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com