Processing method of fresh frozen product packaging bag

A processing method and packaging bag technology, which is applied in the processing field of fresh and frozen food packaging bags, can solve the problems of fresh food packaging bags such as wear and tear, and achieve the effects of improving energy utilization, reducing relative motion, and avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is further described in detail through specific implementation methods:

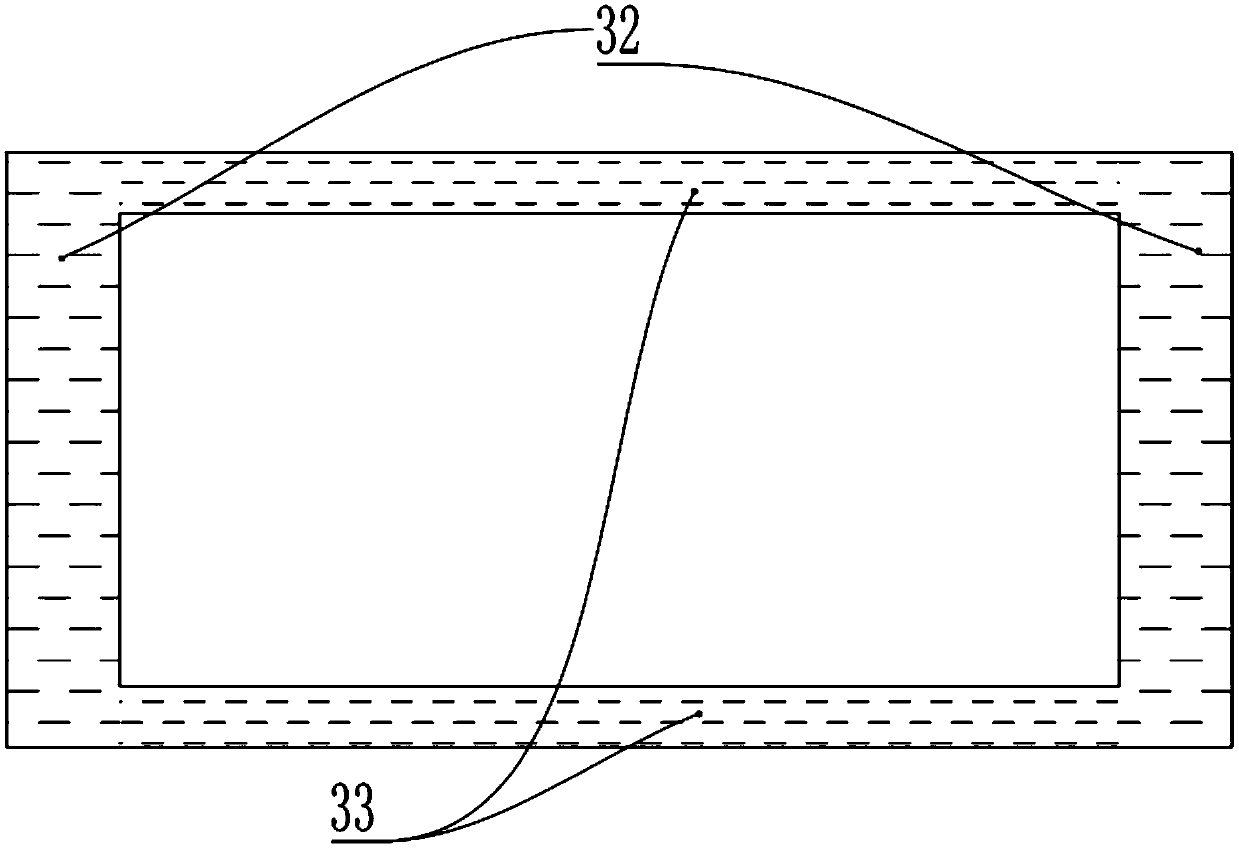

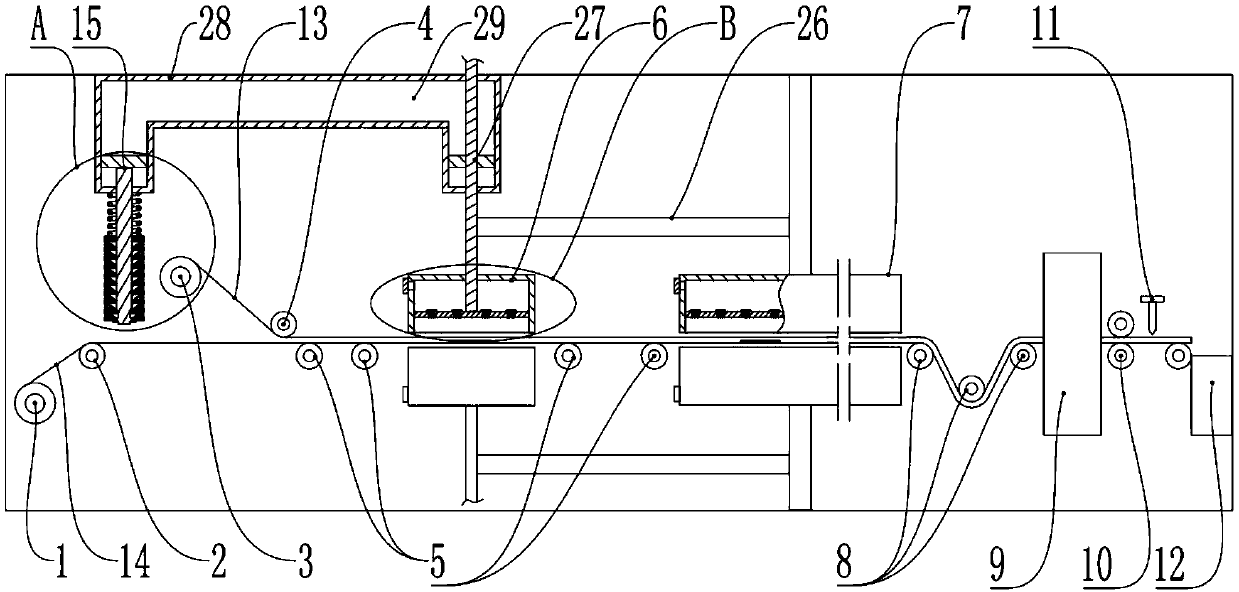

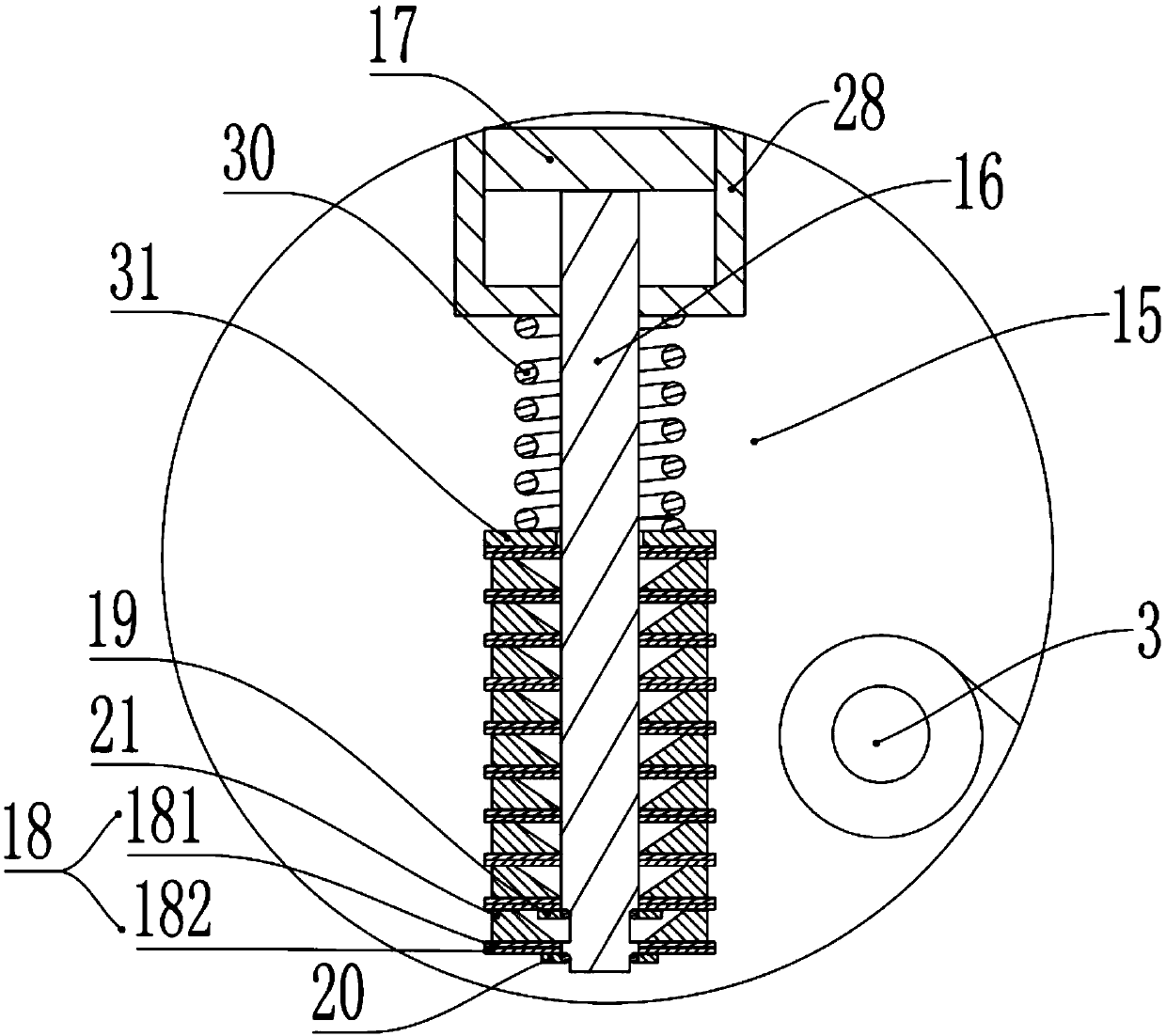

[0037] The reference signs in the accompanying drawings of the specification include: unwinding roller 2 1, guide roller 1 2, unwinding roller 1 3, guide roller 2 4, conveying roller 5, transverse heat-sealing unit 6, longitudinal heat-sealing unit 7, flattening Roller 8, cooling unit 9, traction roller 10, cutting unit 11, collecting unit 12, upper film 13, lower film 14, placing unit 15, piston rod 16, piston one 17, connecting belt 18, upper connecting belt 181, lower Connecting belt 182, long baffle 19, short baffle 20, support block 21, moving rod 22, heat sealing cylinder 23, heat sealing plate 24, one-way air intake valve 34, blocking block 25, connecting rod 26, piston 2 27 , sealing cylinder 28, airtight cavity 29, stage clip 30, pressing plate 31, horizontal seal 32, vertical seal 33.

[0038] A processing method for fresh and frozen product packaging bags, the processing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com