Covellite and pyrite flotation separation collecting agent and preparation method thereof

A technology of pyrite and collector, which is applied in the field of collector and preparation of flotation separation of copper blue and pyrite, can solve the problem that the purity and yield of synthetic products cannot be guaranteed, and can reduce the tension Electron induction effect, increasing electron density, strong collecting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation of embodiment 1 copper blue and pyrite single mineral

[0021] The preparation method of the single mineral used in the test is as follows: artificially select high-purity copper blue and pyrite ore nuggets, crush, hand-select and purify, grind, and sieve to obtain -0.014+0.045mm particle size products as test samples for future use, of which , After the copper blue is ground, it has been shaken several times and dried naturally to obtain a high-purity product. The chemical analysis results of single minerals are shown in Table 1.

[0022] Table 1 Chemical analysis results of single minerals

[0023]

Embodiment 2

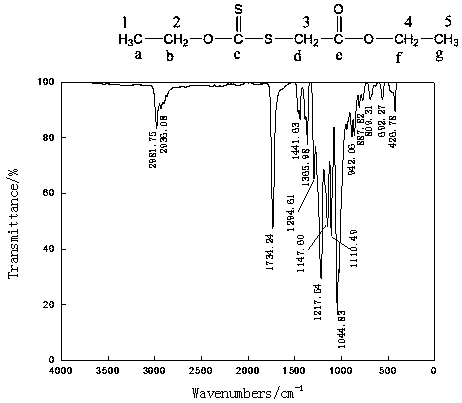

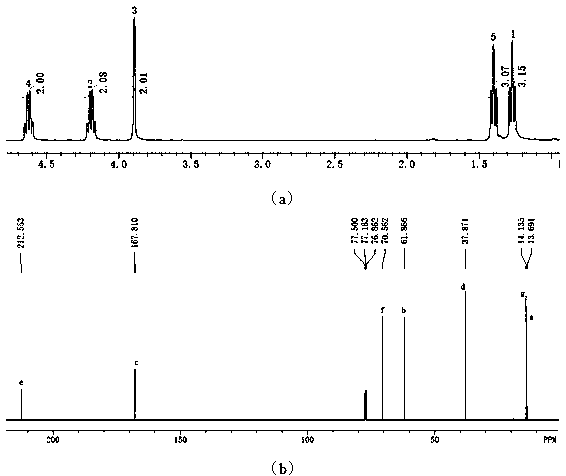

[0024] The synthesis of embodiment 2 ethyl xanthate ethyl acetate

[0025] Add 19.1g of sodium ethyl xanthate into a 250ml round-bottomed three-neck flask to prepare a 2mol / L aqueous solution, slowly add 10ml of ethyl chloroacetate dropwise while stirring, the dropping speed is 1~2 drops / second, and the stirring speed is 400r / min, after the ethyl chloroacetate is completely dripped, react at 50°C for 3 hours. After the reaction, let the cloudy solution stand for stratification, wash the oily solution in the lower layer with distilled water for 3 times, dry it with anhydrous magnesium sulfate overnight, and weigh it , to obtain product 18.8g. After analysis, the product content was determined to be 98.7%, and the yield was 96.39%. The infrared spectrum analysis and nuclear magnetic resonance analysis spectra of the product are shown in figure 1 with figure 2 .

Embodiment 3

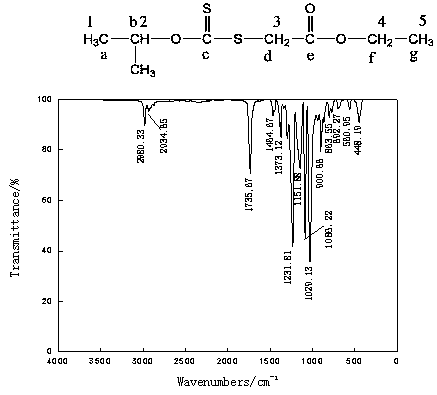

[0026] The synthesis of embodiment 3 isopropyl xanthate ethyl acetate

[0027] Add 21.1g of sodium isopropylxanthate into a 250ml round-bottomed three-neck flask to prepare a 2mol / L aqueous solution, slowly add 10ml of ethyl chloroacetate dropwise while stirring, the dropping speed is 1~2 drops / second, and the stirring speed is 400r / min, react at 50°C for 3 hours after all the ethyl chloroacetate is dripped, after the reaction, put the turbid solution to stand for stratification, wash the oily solution in the lower layer with distilled water for 3 times, dry it with anhydrous magnesium sulfate overnight and weigh Weight, obtain product 19.7 grams. After analysis, the content of the product was determined to be 98.69%, and the yield was 95.49%. The infrared spectrum analysis and nuclear magnetic resonance analysis spectra of the product are shown in image 3 with Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com