Method for controlling preparation of platinum particle highly-dispersed mesoporous carbon-based compound material as high-efficiency hydrogen-producing electrocatalyst

A composite material and mesoporous carbon technology, applied in the field of nanomaterials, can solve the problems of not meeting the needs of industrial development, low catalytic activity, high price, etc., to achieve increased electrocatalytic active sites, good catalytic properties, and high porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]Dissolve 50mg of zirconium chloride, 50mg of tetracarboxyporphyrin and 2700mg of benzoic acid in 8mL of N,N-diethylformamide, and sonicate until it dissolves evenly. Pour this mixed solution into a 25mL polytetrafluoroethylene reaction kettle. Place in the oven at 120°C for 48 hours, then set the oven temperature to 130°C for 24 hours. After the reactor was naturally cooled to room temperature, a reddish-brown precipitate precipitated out at the bottom of the reactor, and was centrifuged and washed with ethanol for several times until the supernatant became colorless and transparent, and the reddish-brown precipitate was dried to obtain a loaded precursor. Weigh it according to the mass ratio of the loaded precursor to ammonium chloroplatinate as 2:1 and place it in a 25mL glass reaction bottle, add 10ml of N,N-dimethylformamide, and sonicate until the dispersion is uniform . Put it into an oven, keep it at 85 degrees Celsius for 48 hours, and then cool it naturally to...

Embodiment 2

[0049] Dissolve 550mg of zirconium chloride, 550mg of tetracarboxyporphyrin and 29.7g of benzoic acid in 88mL of N,N-diethylformamide, and sonicate until it dissolves evenly. Pour this mixed solution into a 200mL polytetrafluoroethylene reaction kettle. Put it in an oven, keep it at 125 degrees Celsius for 36 hours, and keep it at 135 for 30 hours. After the reactor was naturally cooled to room temperature, a reddish-brown precipitate precipitated out at the bottom of the reactor, and was centrifuged and washed with ethanol for several times until the supernatant became colorless and transparent, and the reddish-brown precipitate was dried to obtain a loaded precursor. According to the mass ratio of the loaded precursor to ammonium chloroplatinate of 3:1, it was weighed and placed in a 25 ml glass reaction bottle, 10 ml of water was added, and ultrasonicated until the dispersion was uniform. Put it into an oven, keep it at 80 degrees Celsius for 24 hours, and then cool it nat...

Embodiment 3

[0051] The composite material prepared in Example 1 was tested.

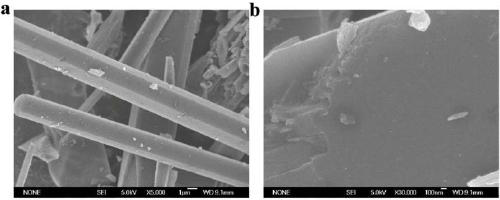

[0052] The scanning electron microscope image of the loaded precursor and platinum particles highly dispersed mesoporous carbon matrix composite was characterized by a JSM-6700 scanning electron microscope;

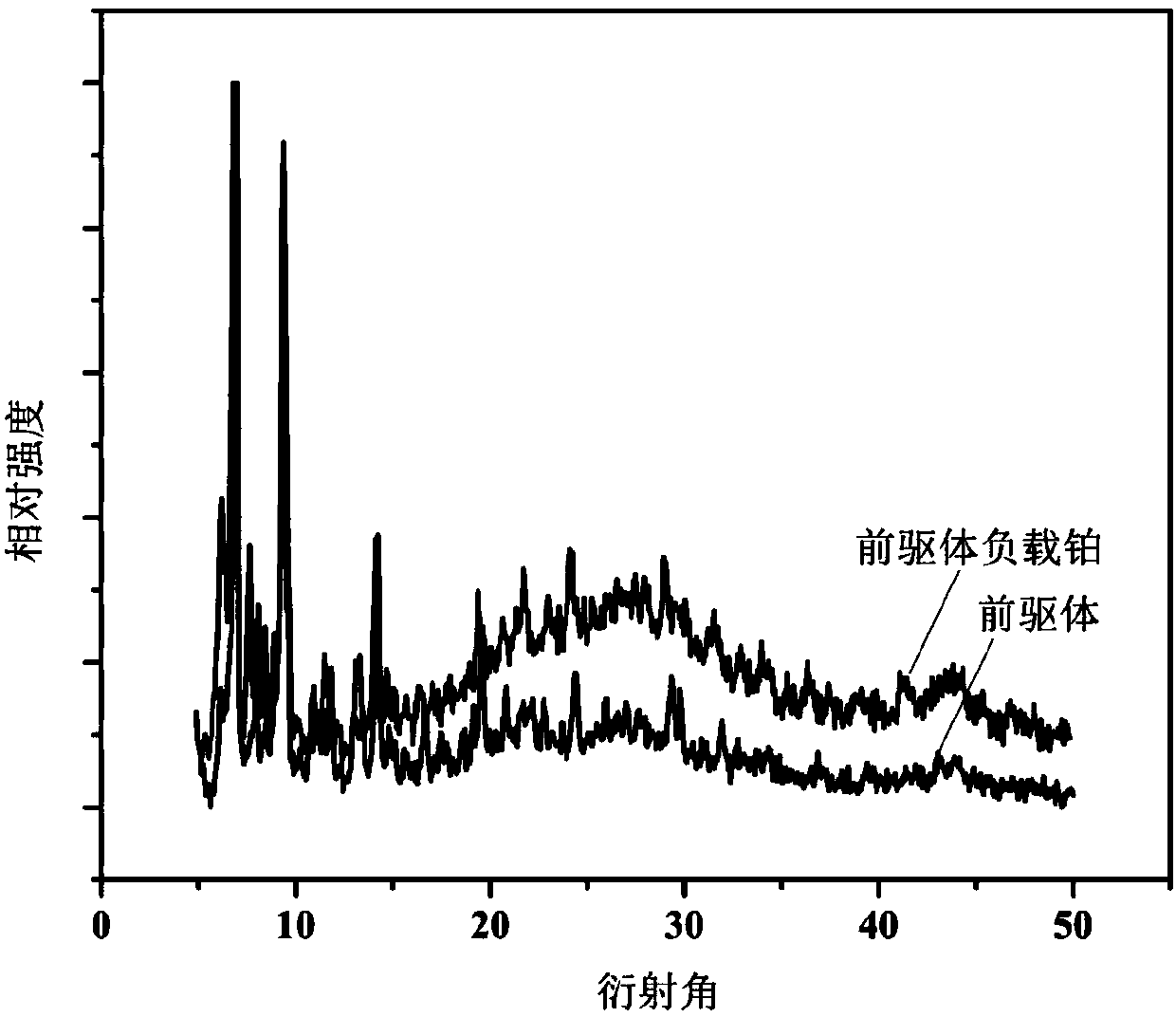

[0053] The powder diffraction pattern before and after loading the precursor with platinum is characterized by a MiniFlex II powder diffractometer;

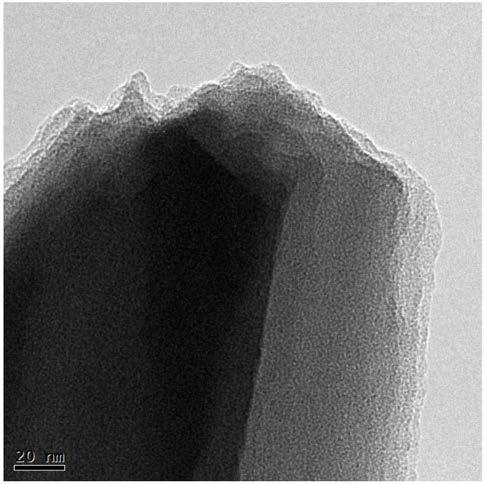

[0054] The transmission electron microscope images of loaded precursors and platinum particles highly dispersed mesoporous carbon matrix composites were characterized by TecnaiG2F20 transmission electron microscope;

[0055] The electrocatalytic hydrogen production experiment of platinum particles highly dispersed mesoporous carbon matrix composites was completed by electrochemical workstation CHI760E.

[0056] figure 1 SEM image of the loaded precursor prepared for Example 1. a represents the 5000 times magnified scanning electron microscope image of the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum particle size | aaaaa | aaaaa |

| Minimum particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com