Electrically injected silicon-based III-V group edge-emitting nanowire laser and its preparation method

A III-V and nanowire technology, applied in the field of optoelectronics, can solve problems such as easy leakage of photons, absence of optical modes, breakage of III-V nanowires, etc., to achieve the effect of facilitating coupling and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

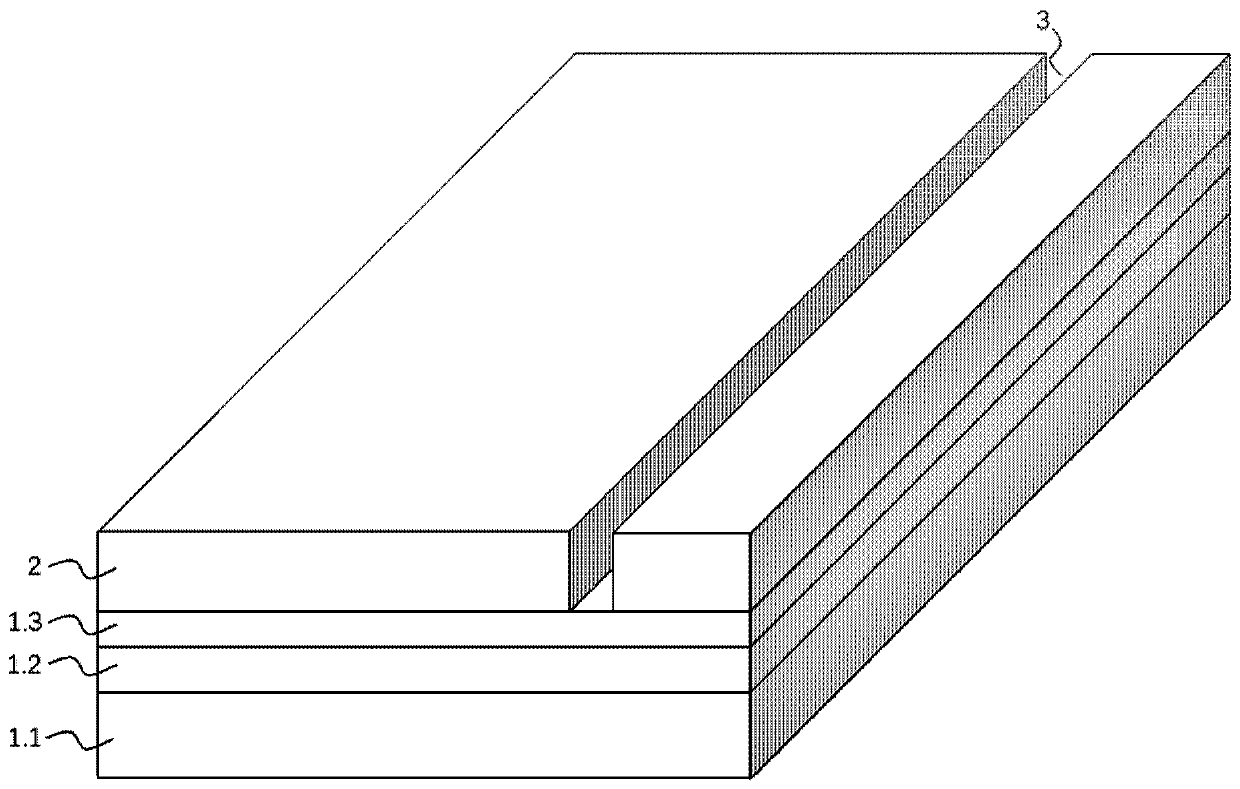

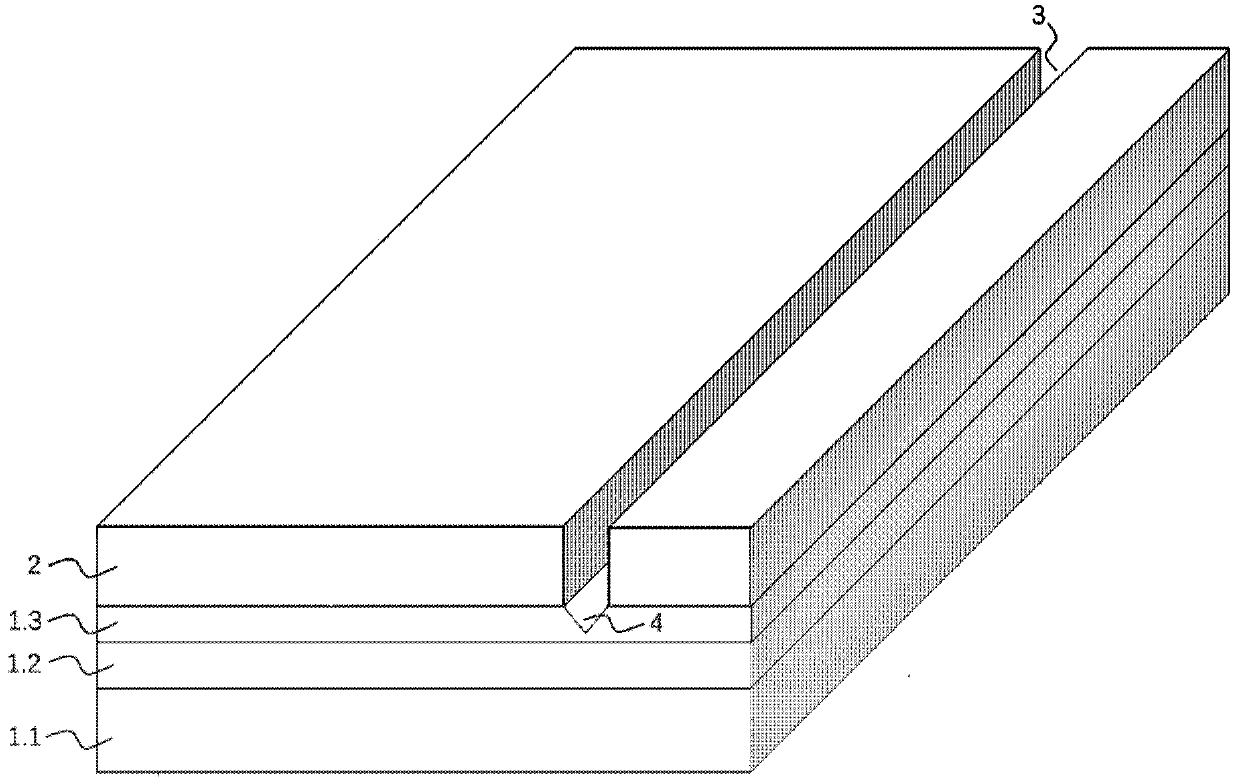

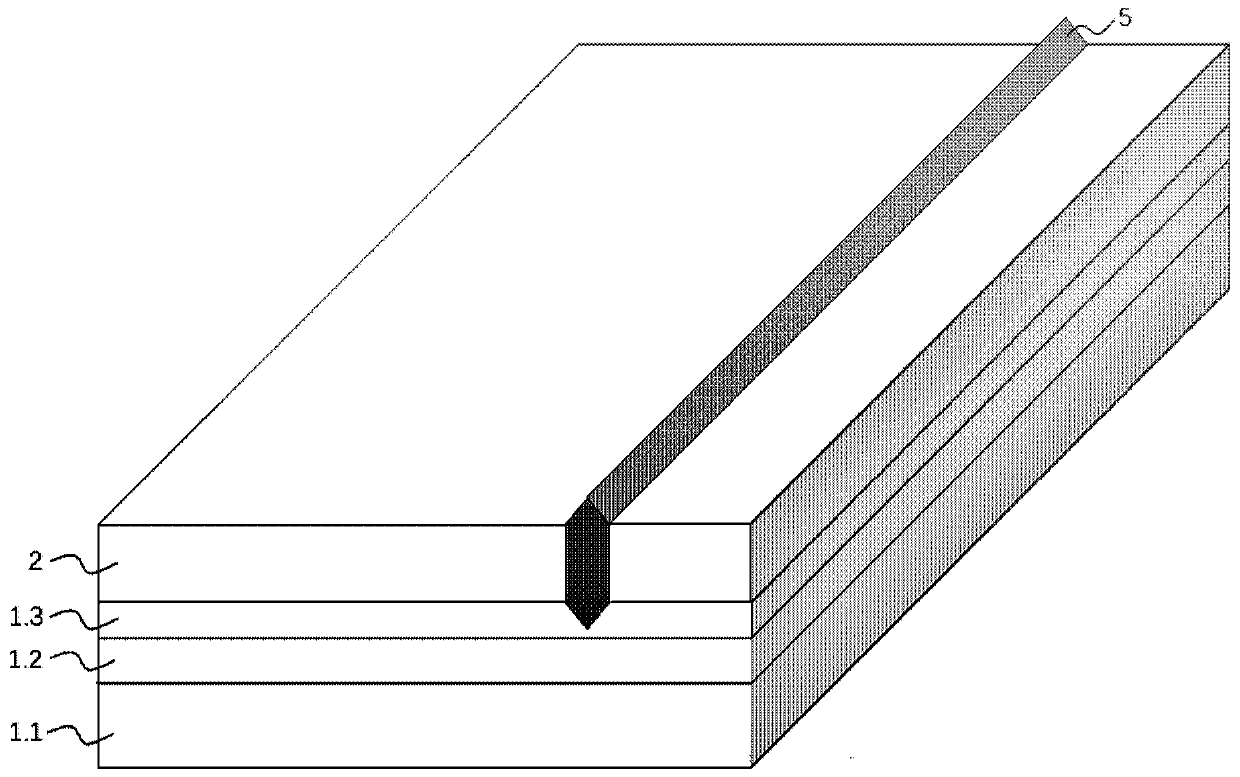

[0055] According to an embodiment of the present invention, there is provided a method for preparing an electrically implanted silicon-based III-V group edge-emitting nanowire laser, including:

[0056] Depositing a silicon dioxide layer on the SOI substrate, and etching rectangular trenches on the silicon dioxide layer;

[0057] Etching a v-shaped groove in the top silicon of the SOI substrate under the rectangular groove to communicate with the rectangular groove to form a connecting groove;

[0058] Growing a silicon-based III-V family side-emitting nanowire laser epitaxial structure in the connecting trench;

[0059] A metal electrode is prepared on the silicon-based III-V group side-emitting nanowire laser.

[0060] The invention provides a process method for realizing electrical injection for III-V family nanowire materials epitaxially on an SOI substrate, and the prepared electrode can be used to test the dynamic characteristics of silicon-based III-V family side-emitting nanowir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com