Fluorescent standard card and test method for calibration and quality control of fluorescent immunoassay analyzer

A fluorescence immunoassay and standard card technology, applied in the fluorescence standard card and testing field of fluorescence analyzer calibration and quality control, can solve the problem that the consistency of the standard card is difficult to guarantee, the performance evaluation of the laser light source of the optical module is difficult, and the signal change of the standard card is difficult to solve. and other problems, to achieve the effect of not easily decaying with time, improving detection accuracy, and evaluating complete content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

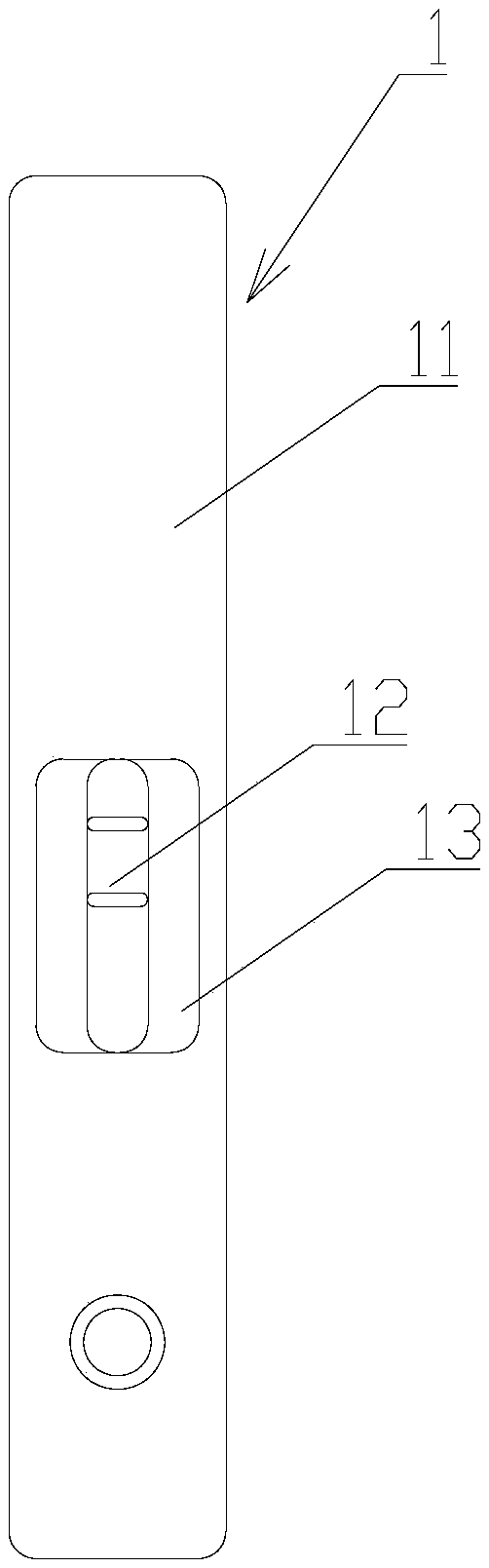

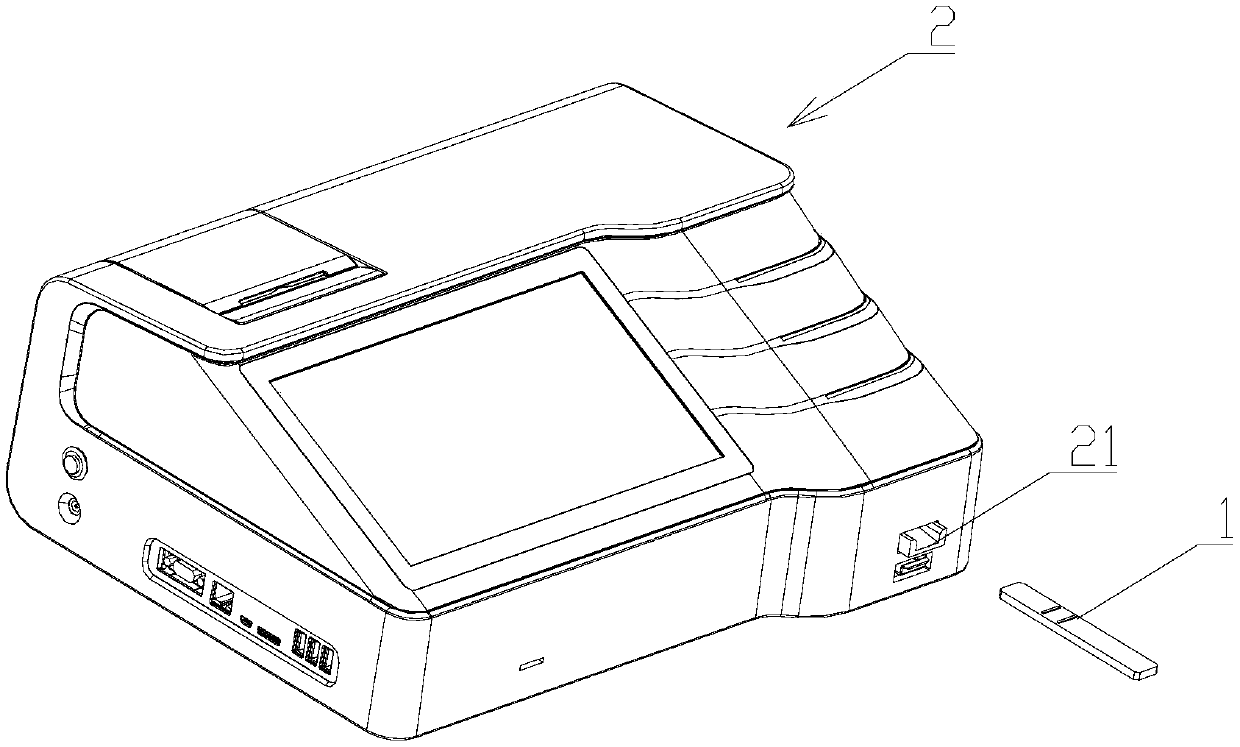

[0030] This embodiment provides a fluorescent standard card for calibration and quality control of a fluorescent immunoassay analyzer, please refer to figure 1 , the fluorescent standard card 1 includes a fluorescent standard card body 11 and a fluorescent detection unit 12, and the fluorescent detection unit 12 is made of fluorescent solution, photocurable fluorescent material, fluorescent ink or fluorescent ink.

[0031] Specifically, the fluorescent standard card body 11 is a shell made of organic materials, metal materials, inorganic non-metallic materials or wood, and has an observation window 13, and a detection card is arranged in the observation window 13, and the detection card A groove for accommodating the fluorescent detection unit 12 is arranged on the top, the groove is in the shape of a strip, and a fluorescent solution is arranged in it, and the groove containing the fluorescent solution forms a detection line, and the fluorescent solution is made of a fluoresce...

Embodiment 2

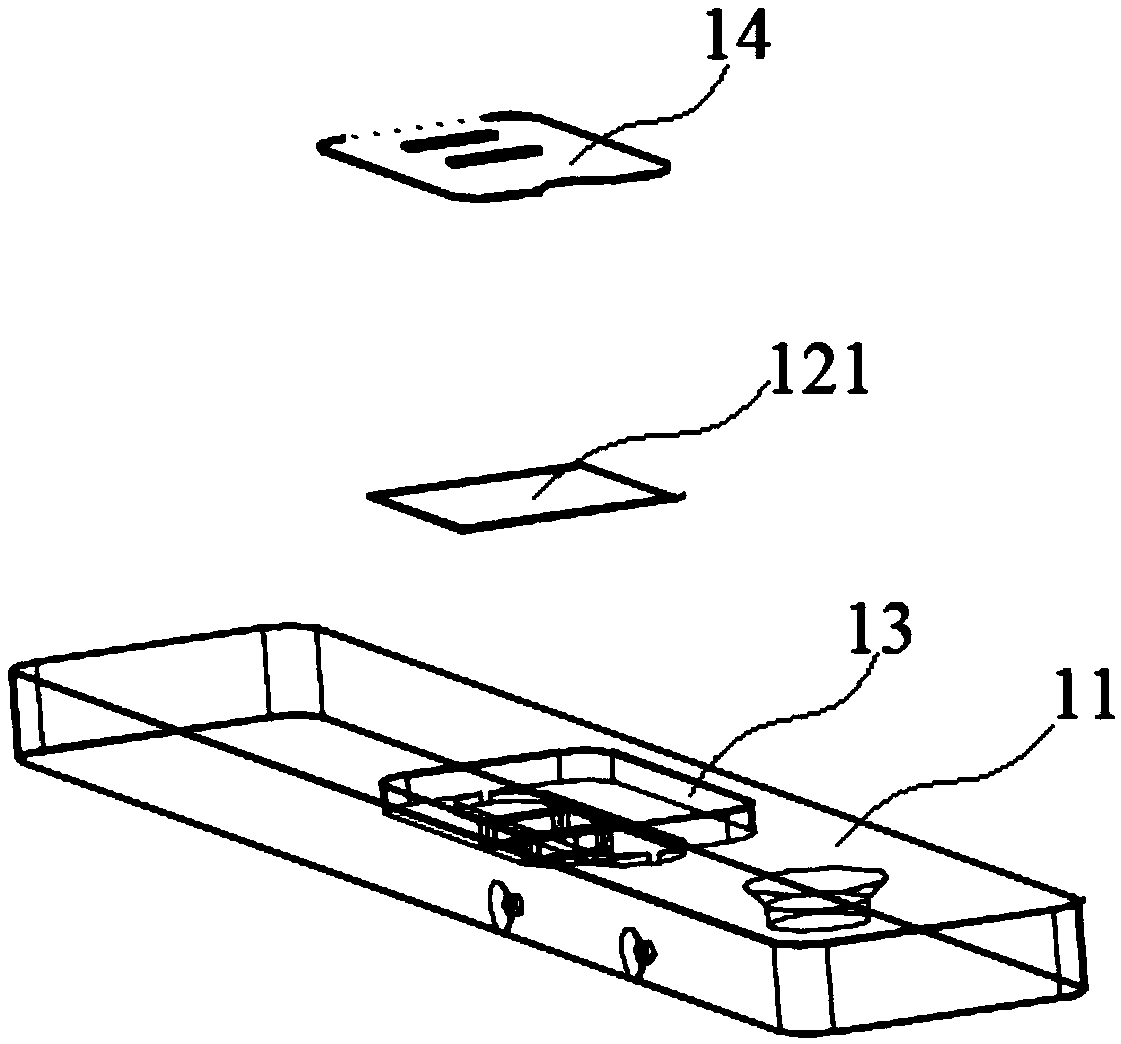

[0038] This embodiment provides a fluorescent standard card for calibration and quality control of a fluorescent immunoassay analyzer, please refer to image 3 , which includes a fluorescent standard card body 1 and a fluorescent detection unit 12, the fluorescent detection unit 12 is made of fluorescent ink or fluorescent ink, fluorescent pigments, fluorescent inks, fluorescent inks contain anti-aging agents and stabilizers, wherein the fluorescent substance It has good dispersion and particle uniformity, and has higher stability than other conventional fluorescent materials. It is arranged in the fluorescent standard card body 1 . In this embodiment, the fluorescence detection unit 12 includes a slide 121, the surface of which is printed or printed with a fluorescence detection part, the fluorescence detection part is a printed or printed fluorescent ink layer or a fluorescent ink layer, and the fluorescence detection part Part can be observed from the observation window 13...

Embodiment 3

[0041] This embodiment also provides a test method for calibrating and quality-controlling a fluorescent immunoassay analyzer using the fluorescent standard card described in Examples 1 and 2, using the relationship between the fluorescence intensity and the concentration of the fluorescent substance, and the relationship between the fluorescence intensity and the luminescent area According to the principle, the performance of the equipment is evaluated by the concentration reference method and the area reference method respectively.

[0042] 1. Concentration reference method

[0043] Within a certain concentration range, the solution concentration of the fluorescent substance has a linear relationship with the light intensity (Lambert-Beer’s law). The degree of internal dispersion remains unchanged, that is, the concentration of the space remains unchanged. Since the light-curing adhesive is a transparent substance, it does not affect the transmission of light. Therefore, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com