Chemical enhancement SERS substrate preparation method for regulating oxide defects

An oxide and defect technology, applied in the field of spectral analysis technology detection, can solve the problem of low electromagnetic enhancement factor, and achieve the effect of easy operation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

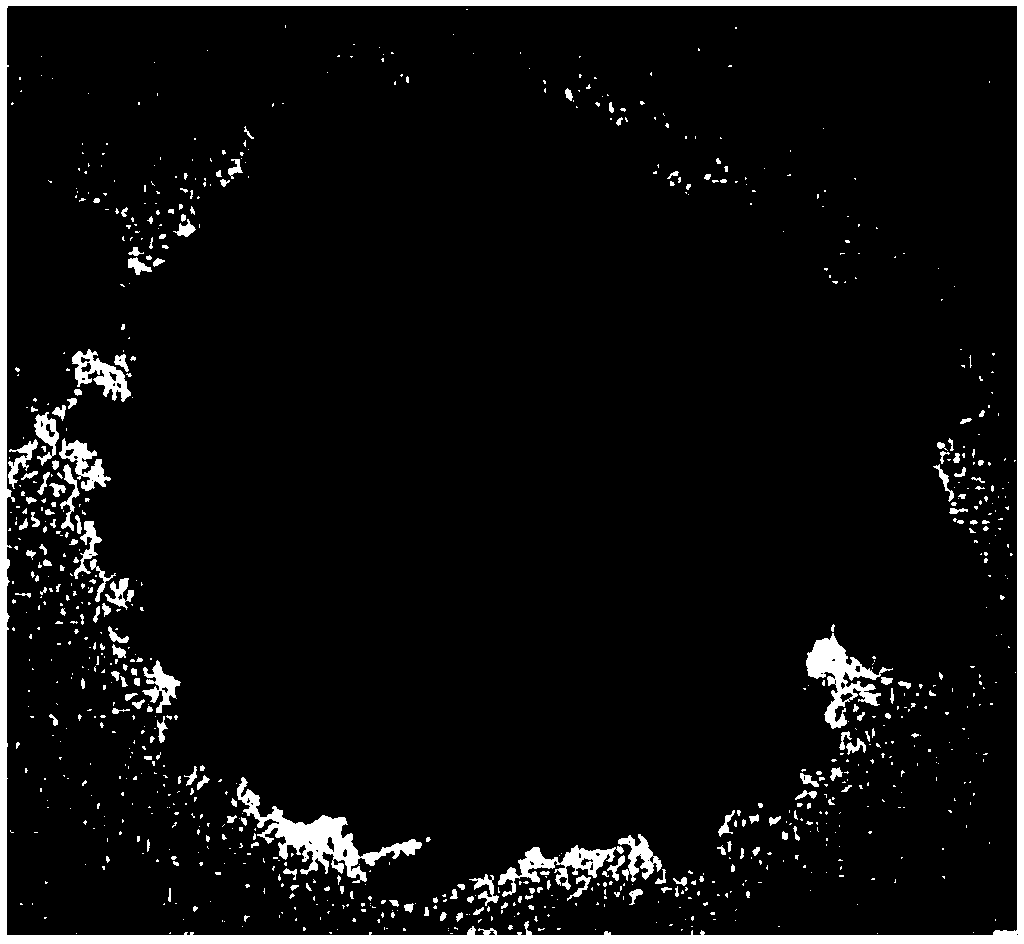

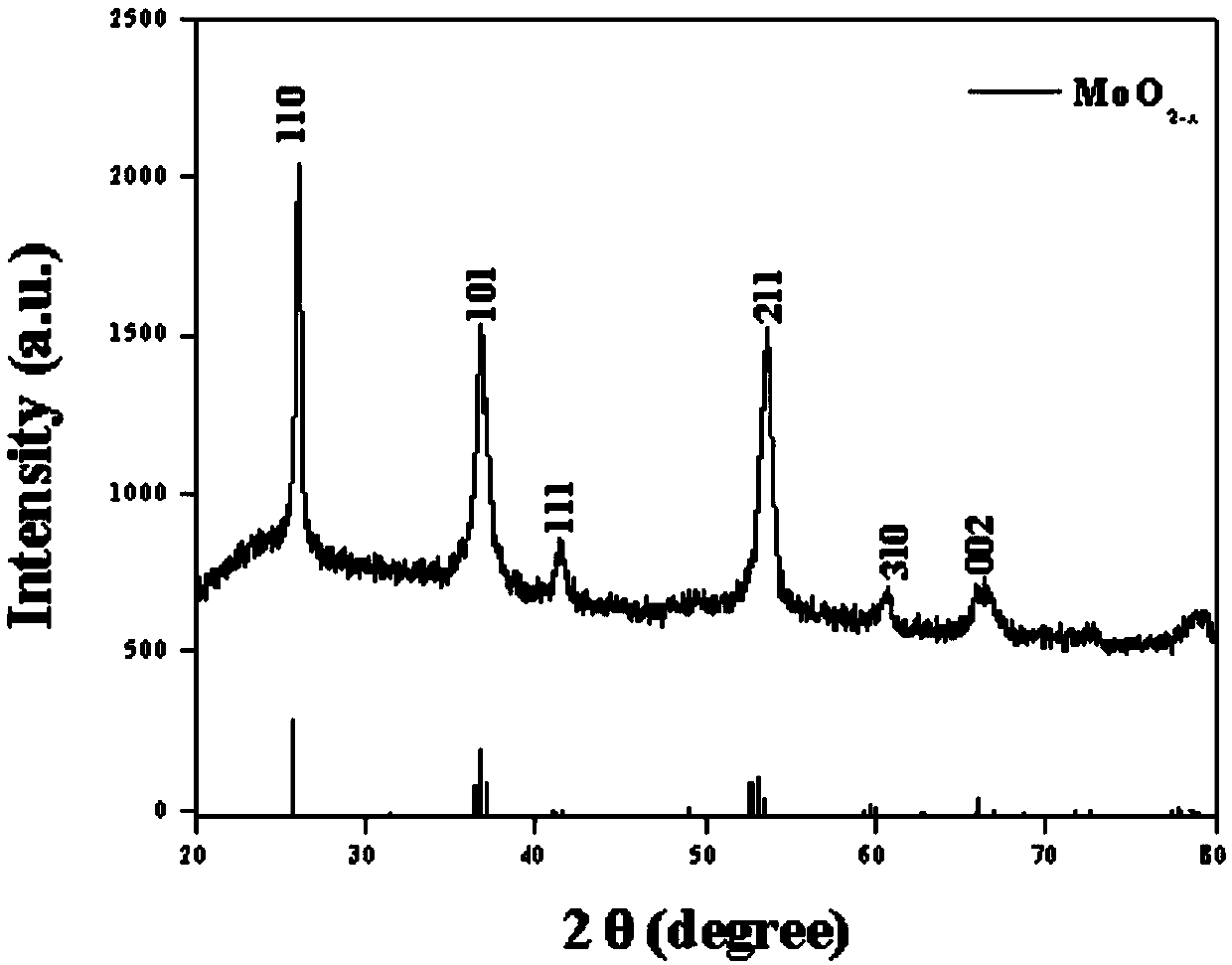

[0024] Adding 2wt% lithium powder to prepare MoO with different concentrations of oxygen-rich defects 2-x (0<x<1) particles, including the following steps:

[0025] Dissolve 1mmol of molybdenum acetylacetonate in a mixed solution of 30ml of absolute ethanol, 10ml of isopropanol, and 10ml of deionized water, and stir magnetically for 2 hours to form a molybdenum source precursor; then transfer the precursor to a polytetrafluoroethylene lining, Seal it in a stainless steel reaction kettle, and place it in a blast drying oven at 180 degrees Celsius to keep warm for 8 hours; finally, after cooling to room temperature, transfer the liquid to a centrifuge tube, wash and centrifuge it with deionized water and absolute ethanol for 3 times, and place it in a vacuum at 60 degrees Celsius. Dry in a drying oven for 6 hours to obtain a uniform MoO 2 Nanospheres; Take 0.5g MoO 2 Add 1ml of dimethyl carbonate to the powder first, then add 10mg of lithium powder in an argon-protected glove ...

Embodiment 2

[0027] Adding 4wt% lithium powder to prepare MoO with different concentrations of oxygen-rich defects 2-x (0

[0028] Dissolve 1mmol of molybdenum acetylacetonate in a mixed solution of 30ml of absolute ethanol, 10ml of isopropanol, and 10ml of deionized water, and stir magnetically for 2 hours to form a molybdenum source precursor; then transfer the precursor to a polytetrafluoroethylene lining, Seal it in a stainless steel reaction kettle, and place it in a blast drying oven at 180 degrees Celsius to keep warm for 8 hours; finally, after cooling to room temperature, transfer the liquid to a centrifuge tube, wash and centrifuge it with deionized water and absolute ethanol for 3 times, and place it in a vacuum at 60 degrees Celsius. Dry in a drying oven for 6 hours to obtain a uniform MoO 2 Nanospheres; Take 0.5g MoO 2 Add 1ml of dimethyl carbonate to the powder first, then add 21mg of lithium powder in an argon-protected glove ...

Embodiment 3

[0030] Adding 6wt% lithium powder to prepare MoO with different concentrations of oxygen-rich defects 2-x (0

[0031] Dissolve 1mmol of molybdenum acetylacetonate in a mixed solution of 30ml of absolute ethanol, 10ml of isopropanol, and 10ml of deionized water, and stir magnetically for 2 hours to form a molybdenum source precursor; then transfer the precursor to a polytetrafluoroethylene lining, Seal it in a stainless steel reaction kettle, and place it in a blast drying oven at 180 degrees Celsius to keep warm for 8 hours; finally, after cooling to room temperature, transfer the liquid to a centrifuge tube, wash and centrifuge it with deionized water and absolute ethanol for 3 times, and place it in a vacuum at 60 degrees Celsius. Dry in a drying oven for 6 hours to obtain a uniform MoO 2 Nanospheres; Take 0.5g MoO 2 First add 1ml of dimethyl carbonate to the powder, then add 32mg of lithium powder in an argon-protected glove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com