Material constitutive test method under complex stress condition

A technology of complex stress and testing methods, which is applied in the analysis of materials, testing the strength of materials by applying stable bending force, testing the strength of materials by applying stable tension/pressure, etc. It can solve the problem that the constitutive relationship cannot be established and the material cannot be fully reflected. Problems such as mechanical properties, inability to accurately predict molding defects and material constitutive relations, etc., to achieve accurate and referential test results, and to improve the application field and use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

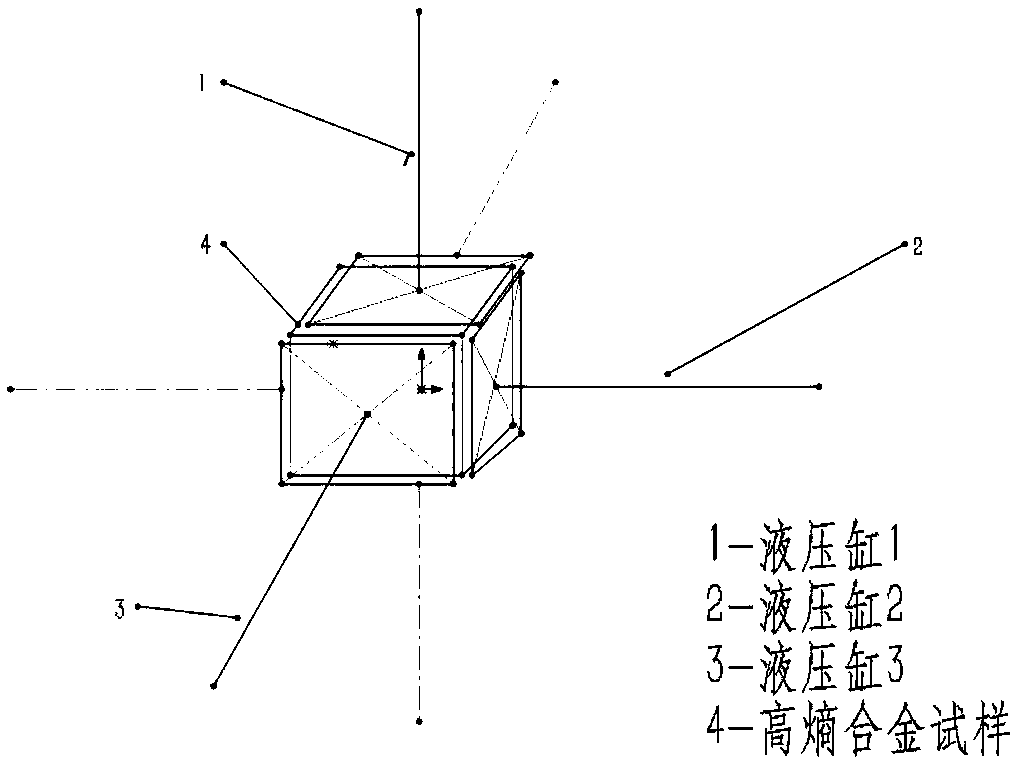

[0013] Take the two-way compression and one-way tension of the material at 100°C as an example to illustrate. The specific implementation steps are as follows:

[0014] (1) Open the chuck, clamp the sample on the three sets of chucks and fix it at the same time, control the temperature through the program, and heat the temperature of the high-temperature box to 100 °C.

[0015] (2) When the temperature of the workbench reaches the required temperature, by controlling the movement of the transmission shaft of the hydraulic cylinder, the hydraulic cylinders in the upper and lower directions and the front and rear directions are simultaneously compressed to provide pressure for the sample. When the pressure value reaches the required value, make the It stops moving and keeps the pressure value constant.

[0016] (3) Control the drive shafts in the left and right directions to start stretching movement, provide tensile force to the sample, collect data during the process of conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com