A rapid evaporation electrospray ion source and analysis method

An electrospray ion source and rapid evaporation technology, which is applied in the direction of ion source/gun, material analysis and material analysis through electromagnetic means, can solve the problems of small heating area, poor heat transfer efficiency, and low heating efficiency, and achieve improvement Effect of heating area, improving heat transfer efficiency, and increasing specific area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

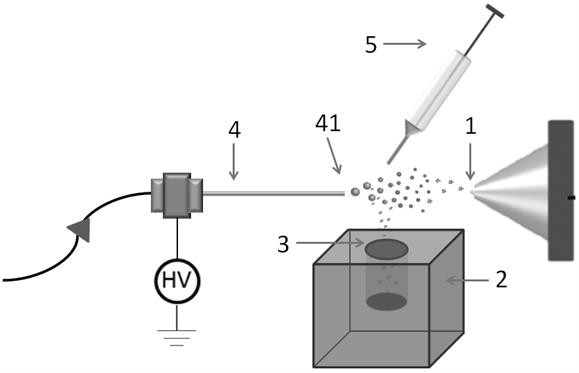

[0040] A fast evaporation electrospray ion source device (such as figure 1 shown): It consists of four parts: electrospray generating unit (4), heating unit (2), vaporization chamber (3) and sampling unit (5).

[0041] The mass spectrometer inlet (1) is located at the far right; the leftmost is the electrospray generator unit (4), and the tip (41) of the electrospray generator unit is located on the axis of the mass spectrometer inlet (1), and the distance from the mass spectrometer inlet (1) is about 3-10cm; the gasification chamber (3) is placed inside the heating unit (2), the outlet of the gasification chamber (3) is located below the axis of the mass spectrometer inlet (1), and the horizontal distance from the mass spectrometer inlet (1) is 0 -5cm, the vertical distance from the mass spectrometer inlet (1) axis is 0-5cm, and is located between the tip of the electrospray generation unit and the mass spectrometer inlet; the sampling unit (5) is located directly above the o...

Embodiment 2

[0048] This embodiment adopts the rapid evaporation electrospray ion source device described in Embodiment 1 ( figure 1 ) combined with a mass spectrometry system to analyze thermally unstable compounds, with mesaconitine as the detection object. The electrospray voltage was 3 KV, the spray solvent was methanol, and the spray solvent flow rate was 3 μL / min. The diameter of the gasification chamber is 3mm, the height is 3mm, and the temperature is set at 125°C.

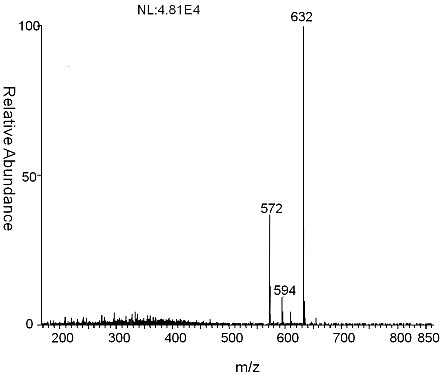

[0049] The method of operation is the same as in Example 1. Use a pipette to draw 6.5 μL of aconitine methanol solution with a concentration of 6mg / L and drop it into the hot vaporization chamber. The sample evaporates rapidly, and the sample vapor is ionized by electrospray at the mass spectrometer inlet (1), forming ions and entering the mass spectrometer is detected. In the normal spectrum mode, the spectrum is obtained as figure 2 As shown, compared with the thermal shock gasification technology (ZL20161001882...

Embodiment 3

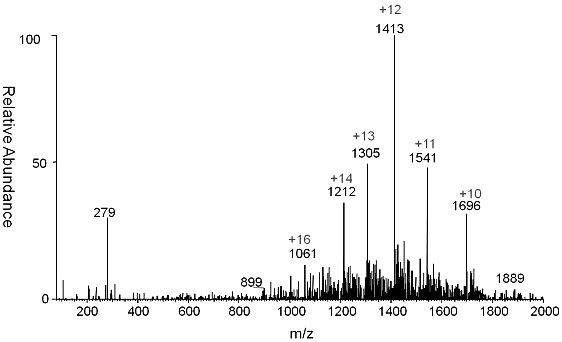

[0051] This embodiment adopts the rapid evaporation electrospray ion source device described in Embodiment 1 ( figure 1 ) combined with a mass spectrometry system to analyze biological macromolecules, taking myoglobin and cytochrome C as examples. The electrospray voltage was 4 KV, the spray solvent was methanol:water (30:70, v / v) solution containing 0.1% (v) acetic acid, and the spray solvent flow rate was 5 μL / min. The diameter of the gasification chamber is 5mm, the height is 5mm, and the temperature is set at 200°C. Myoglobin and cytochrome C were dissolved in water to prepare 59 μM and 100 μM aqueous solutions, respectively.

[0052] The method of operation is the same as in Example 1. Use a pipette to draw 6.5 μL of myoglobin and cytochrome C aqueous solution dropwise in the vaporization chamber, scan the mass spectrometry data, the results are as follows image 3 , 4 As shown, both myoglobin and cytochrome C produce multi-charged mass spectrum peaks, and the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com